How can industries improve heat exchanger efficiency while saving space and reducing costs? A plate-and-frame heat exchanger is a reliable solution for heating and cooling in various applications. It efficiently transfers heat between fluids, making it useful in HVAC, food processing, and power plants. Its compact design, easy maintenance, and scalability make it different from other heat exchangers. This article explains how it works, its benefits, and how to choose the right industrial heat exchanger.

How a Plate and Frame Heat Exchanger Works

Discover our most popular product categories – find what you need today!

- Air to Water Heat Exchangers

- Water to Air Heat Exchangers

- Plate Heat Exchangers

- Oil Coolers & Intercoolers

- Tankless Water Heaters

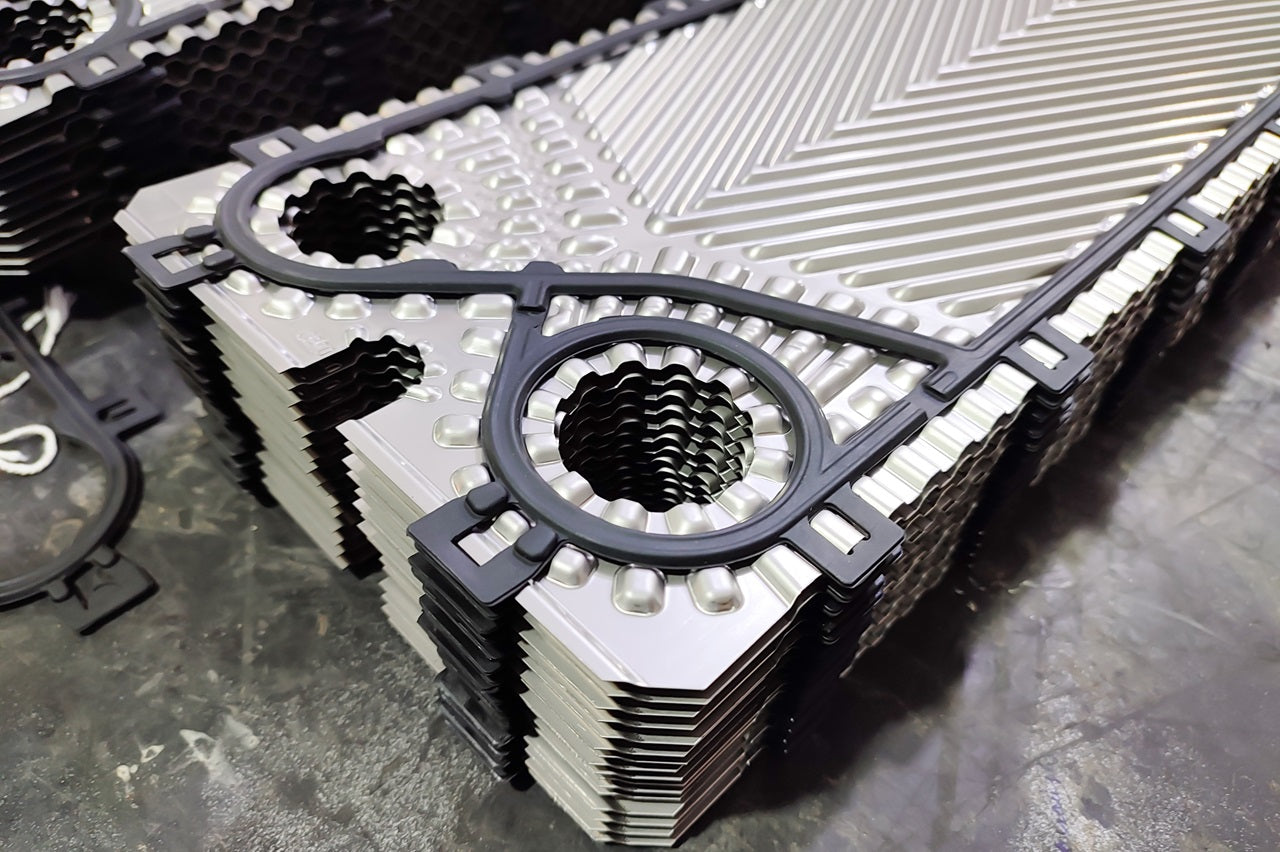

A plate and frame heat exchanger consists of multiple thin plates that create channels for hot and cold fluids. These plates increase the surface area for heat transfer, improving heat exchanger efficiency. The key working principles include:

- Parallel flow design – Fluids move between alternating plates to maximize heat transfer.

- Gasket or brazed sealing – Ensures no mixing of hot and cold fluids.

- Compact structure – Requires less space compared to traditional heat exchangers.

These features make them ideal for critical space, maintenance, and performance industries.

Key Benefits of Plate and Frame Heat Exchangers

The efficiency of an industrial heat exchanger depends on its design and application. A plate and frame heat exchanger offers several advantages:

- Higher thermal efficiency – Thin plates allow better heat transfer than shell and tube exchangers.

- Easy maintenance – The modular design allows easy disassembly and cleaning.

- Compact size – Saves space in industrial settings.

- Scalability – Additional plates can be added to increase capacity.

- Cost savings – Improved heat exchanger efficiency reduces energy consumption.

These benefits make them a preferred choice in industries requiring high-performance thermal management.

Common Applications in Industry

A plate and frame heat exchanger is widely used across industries due to its adaptability and efficiency. Some common applications include:

- HVAC systems – Regulates heating and cooling in buildings.

- Food and beverage processing – Maintains temperature in pasteurization and brewing.

- Chemical processing – Supports controlled reactions with precise heat exchange.

- Power generation – Helps in cooling systems and waste heat recovery.

- Pharmaceutical industry – Ensures proper temperature control during production.

A high heat exchanger efficiency is crucial for maintaining process stability and reducing operational costs in each application.

Choosing the Right Plate and Frame Heat Exchanger

Selecting an industrial heat exchanger requires careful consideration of several factors:

- Fluid type and properties – Consider viscosity, corrosion potential, and pressure levels.

- Temperature and pressure range – Ensure compatibility with system requirements.

- Material selection – Stainless steel and titanium are common for durability.

- Maintenance needs – Choose between gasketed or brazed exchangers based on cleaning requirements.

- Size and scalability – Ensure the unit can handle future capacity expansion.

Understanding these factors helps industries maximize heat exchanger efficiency while minimizing long-term costs.

Maintenance and Troubleshooting Tips

Regular maintenance ensures that a plate and frame heat exchanger operates at peak efficiency. Key maintenance steps include:

- Cleaning deposits – Scale and debris reduce heat exchanger efficiency over time.

- Inspecting gaskets – Worn gaskets can lead to leaks and efficiency loss.

- Checking for pressure drops – A sudden pressure drop may indicate blockages.

- Monitoring heat transfer performance – Deviations in expected temperature differences signal potential issues.

Proper maintenance reduces downtime and prolongs the lifespan of an industrial heat exchanger.

Why Plate and Frame Heat Exchangers Are a Smart Investment

A plate and frame heat exchanger provides an efficient, cost-effective solution for industries requiring reliable thermal management. Its compact design, high heat exchanger efficiency, and ease of maintenance make it an excellent choice. These heat exchangers optimize performance for HVAC, food processing, and power generation while reducing energy costs. Investing in the right industrial heat exchanger ensures long-term reliability and efficiency.