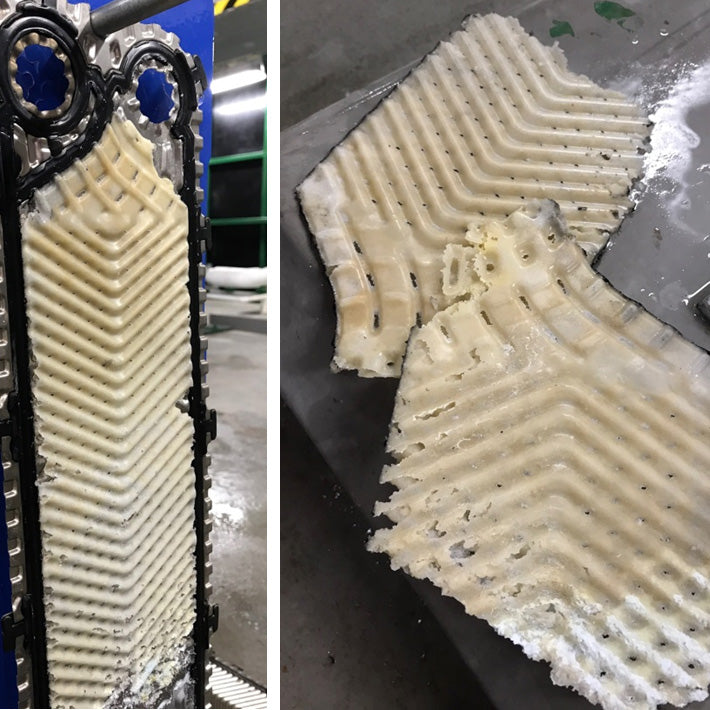

The plate heat exchanger is a widely used cold exchange equipment in the atmospheric and vacuum distillation workshop of a refinery. It costs a lot of money to deal with the scaling of heat exchangers every year, and even affects the production when the problem is serious. According to the deposition mechanism of the scaling layer, the fouling can be divided into particle fouling, crystal fouling, chemical reaction fouling, corrosion fouling and biological fouling.

1) Particle fouling: the accumulation of solid particles suspended in the fluid on the heat exchange surface. This kind of fouling also includes the precipitation layer formed by the gravity action of large solid particles on the horizontal heat exchange surface, that is, the deposition of the so-called precipitation fouling and other colloidal particles.

2) Crystallization fouling: the deposit formed by the crystallization of inorganic salts dissolved in the fluid on the heat exchange surface, usually during supersaturation or cooling. Typical fouling such as calcium carbonate, calcium sulfate and silicon dioxide on the cooling waterside.

3) Chemical reaction fouling: the fouling produced by chemical reaction on the heat transfer surface. The heat transfer surface material does not participate in the reaction but can be used as a catalyst for chemical reactions.

4) Corrosion fouling: fouling caused by corrosion of heat exchange surface by corrosive fluid or corrosive impurities in a fluid. Generally, the degree of corrosion depends on the composition of the fluid, the temperature and the pH value of the treated fluid.

5) Biological fouling: in addition to seawater cooling devices, general biological fouling refers to microbial fouling. It may produce slime, which in turn provides conditions for the propagation of biofouling. Under suitable temperature conditions, biofouling can produce a considerable thickness of the fouling layer.

6) Solidification fouling: fouling formed by solidification of fluid on supercooled heat exchange surface. For example, when water is below zero, it solidifies on the heat exchange surface to form ice. The uniformity of temperature distribution has a great influence on fouling.