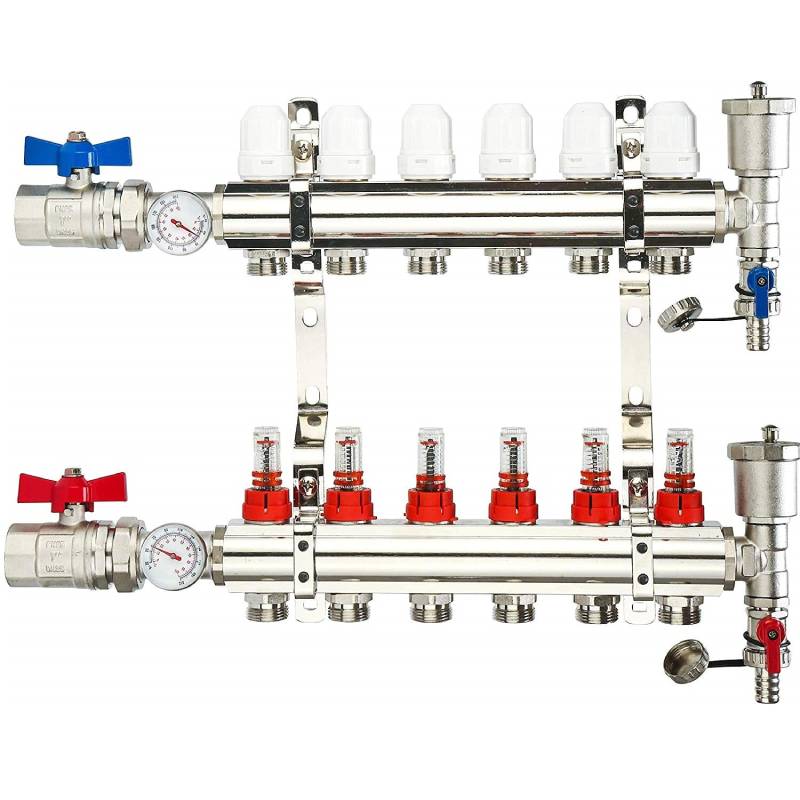

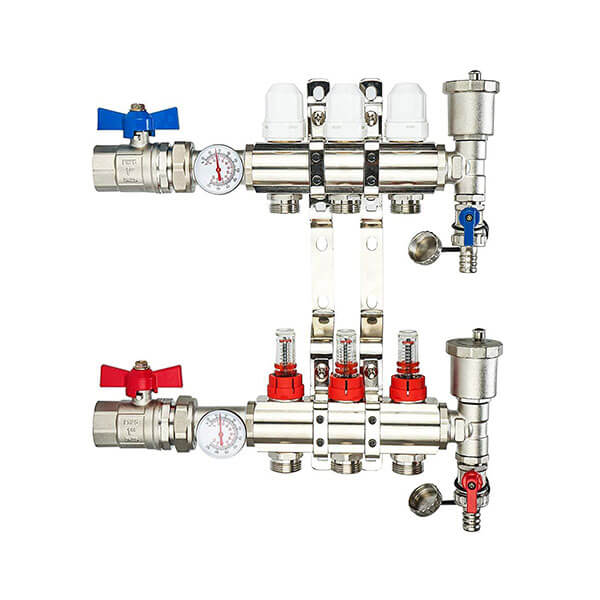

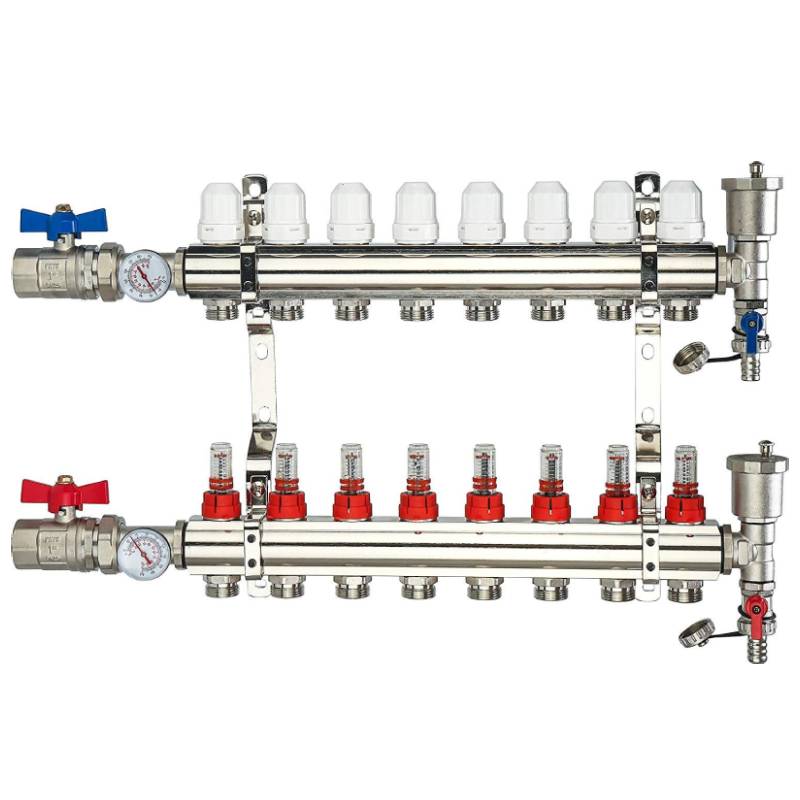

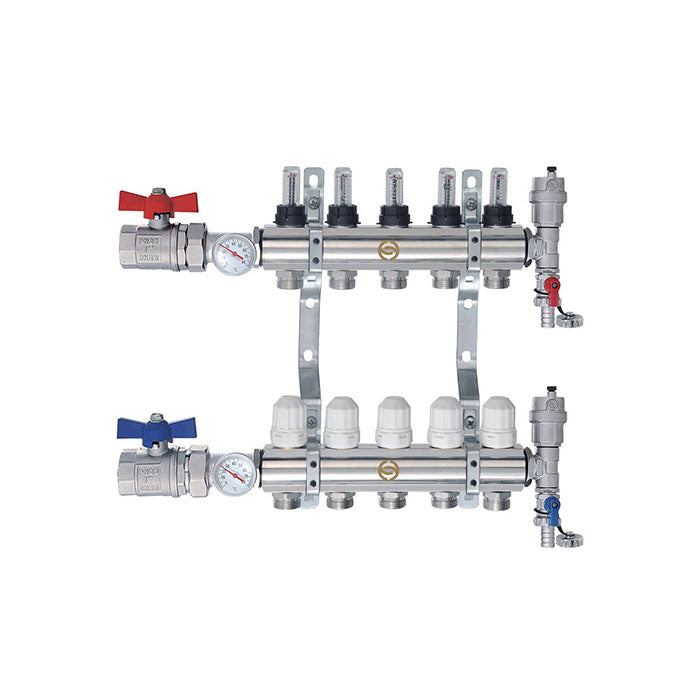

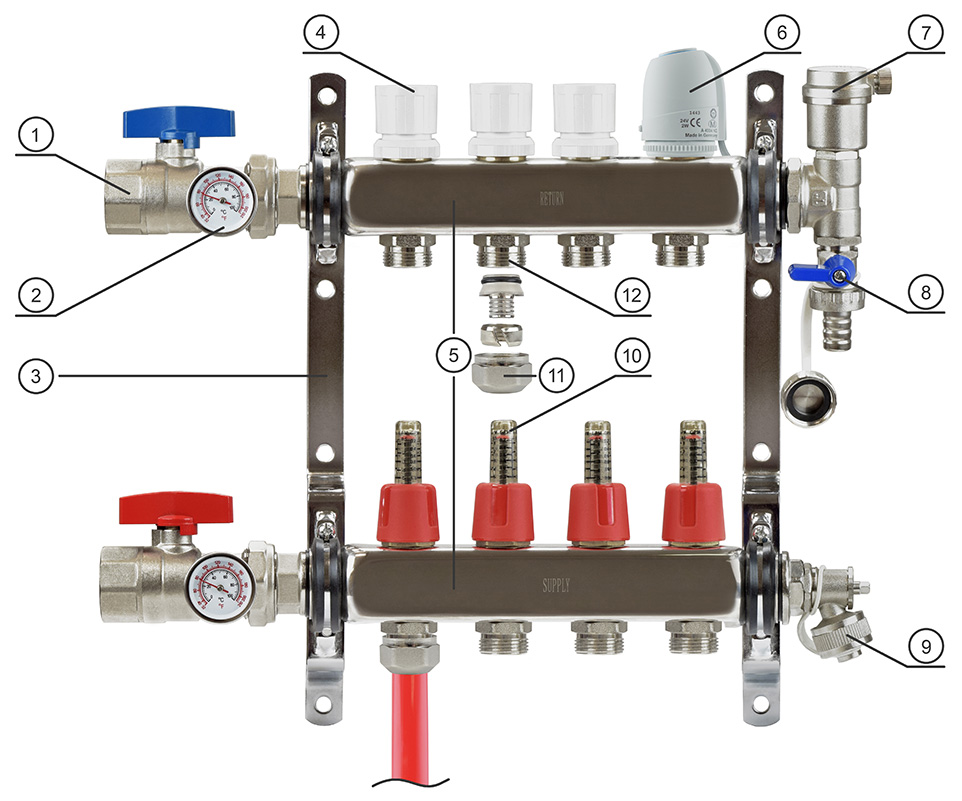

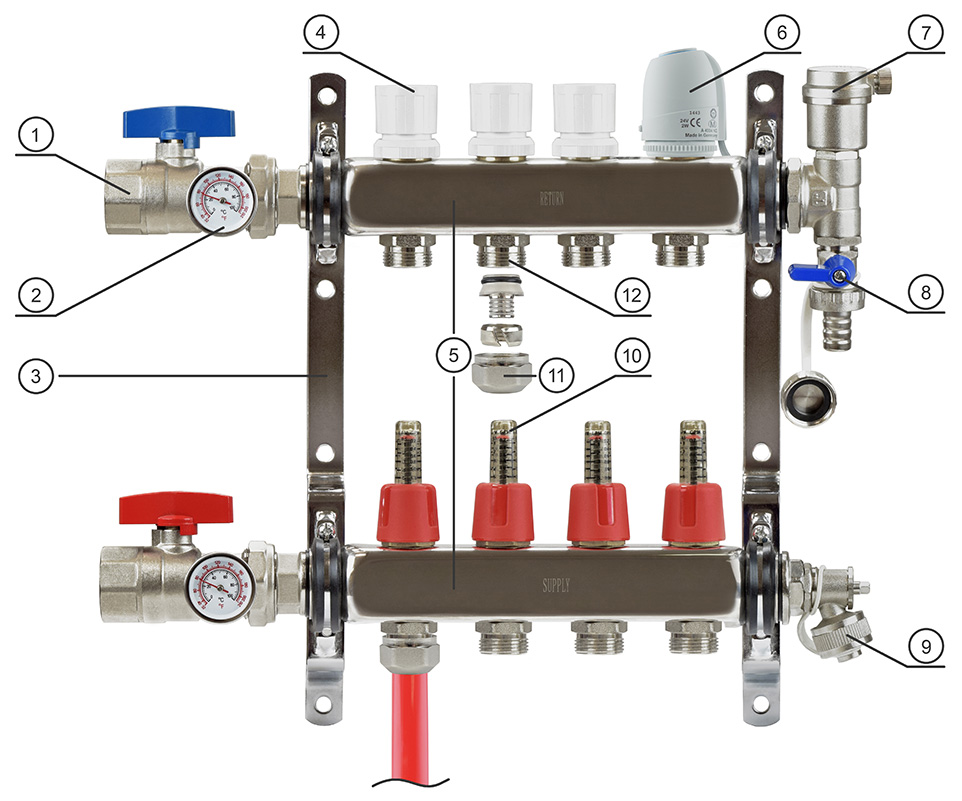

ALFA radiant heating system provide a central control for hot and cold water that feeds flexible PEX supply lines to individual fixtures. Brass manifold plumbing compared to rigid pipe plumbing systems, using this radiant floor heating systems is cheaper because of its size and ability to control many different zones from one place. Our radiant PEX manifold allows you to monitor the water's temperature and flow rate, set up automatic flow controls, drain the system, and more. This particular radiant hot water system is made of brass 57-3, has nickel-plating on the ball valve and air vent valve, and has 1" supply/return ports and 1/2" branch ports (can be converted to 3/4" by using adapters). It includes automatic air vent, shut-off valve, drain valves with outlet caps, temperature gauge, flow valve, balancing valve/manual wheel for supply and return trunks. Its nickeled brass material are higher thermal conductivity, faster heating and insertion into plastic pipes than stainless steel ones.

- Compatible to 1/2" pipes outlets

- Heavy duty stainless steel mounting bracket

- Flow Valve (Meters) - indicates the flow of heat that is distributed throughout the system.

- Shut-Off Valves include 1" NPT connections and temperature gauges to monitor supply and return temperatures.

- 3/4" Drain Valve has adapters and cap for draining and filling of heating system conveniently. With the automatic air eliminators/ air vent, air can be purged from the radiant heat system.

- (1/2 in Adapters Not Included.) -Drop us a message if you need 1/2" or 3/4" Adapters.

Details

- Temperature Gauge, displaying both Fahrenheit (120F) and Celsius (80C) for your convenience

- 1 extra cap on both drain valves can be used to put an outlet on standby

- Manual valves allow adjustment of flow rate

- Shut-off valves on both supply and return outlets

- Drain valve can be used as an extra plumbing outlet

- Zone valve can be used to control different zones

- Air vent valve for purging air during the water filling process.

The underfloor heating system is needed for every household. If you live in cold areas, a radiant manifold underfloor heating is what you need to survive the freezing temperature. Manifold is the system through which you can control the floor heating system. Radiant Manifold consists of an underfloor piping network. The hot water is distributed across the floor to provide warmth. It flows back to the boiler from a separate network to heat again and repeat the cycle.

More About Manifolds for Radiant Heating from WiseWater Alfa Heating Company

The radiant floor manifold is cheaper compared to the other fixed piping heating system. The radiant Manifold has a sizing range to suit your preference. Manifold has a temperature gauge and manual valves for easy temperature control. Moreover, you get the feature to adjust the flow rate and an auto system to drain the water in this radiant floor heating system. The hydronic radiant floor heating manifold is supported by the heavy-duty stainless steel mounting bracket. The nickeled brass material used for this radiant heat manifold guarantees higher thermal conductivity and heats faster.

Manifold Components

A Manifold has multiple components. They are as follows:

- Removable Ball Valves: This shut-off ball valve is part of each manifold system. The valve is easily removable for convenience during cleaning and repairing.

- Thermostat: Radiant heat manifolds have good quality thermostat both on the supply/ flow and return tube to check and adjust the temperature

- Manual Valves: You can balance and set the flow of the Manifold manually through manual valves to maintain the ideal temperature in your house.

- Supply and Return Tubes: The heating boiler in the radiant hydronic floor heating manifold system has two main tubes. The first tube is known as the Supply or Flow tube. The water flows back to the heater via the tube called 'Return Tube'.

- Air Vent: Prevents and removes the air bubble in the radiant floor manifold.

- Main Drain Vale: To fill and drain the water in a hydronic radiant floor heating manifold.

- Adapter and connectors: Connects PEX pipes to the system. (Buy separately)

- Flow Meters: To adjust the pressure and the flow of water in the supply tube.

Sizing

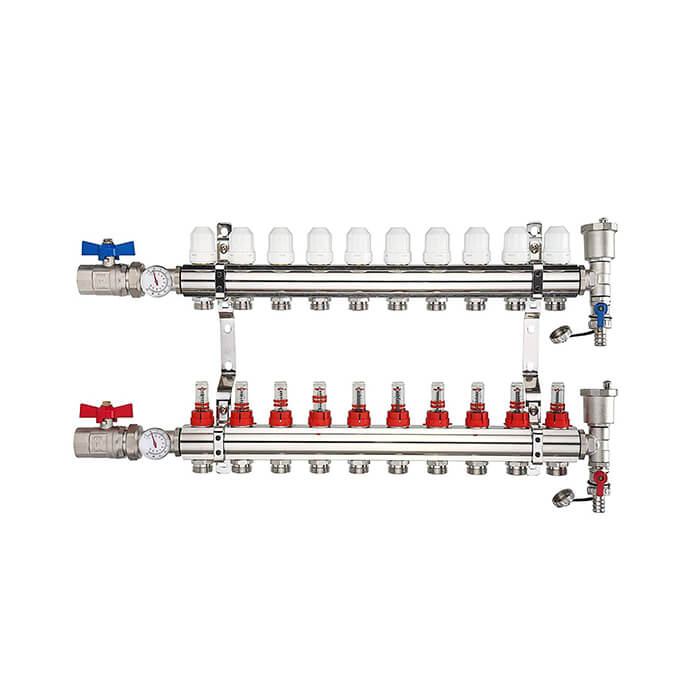

Radiant manifold use 'PEX pipes' that are cost-efficient, can be installed quickly compared to the other methods, and the risk of flames is lower than any other manifold system. A wide range of radiant heat manifolds is available. Refer to the standard sizes below to find the perfect hydronic radiant floor heating manifold for your house.

- Radiant Heat Manifold Brass 2 -3 Loop outlet, Ideal for the space range between 600sq - 800sq feet.

- Radiant Heat Manifold Brass 4 Loop outlet will be sufficient for 800sq - 1200sq feet.

- Radiant Heat Manifold Brass 5-6 Loop outlet, Ideal for the space range between 1000sq- 1300sq feet.

- If the area you want to cover is between 1300sq- 1700sq feet, Hydronic Radiant Heat Manifold Brass 7-8 Loop Outlet is the best to keep the area warm.

- Radiant Heat Manifold Brass 8-9 Outlet for 1700sq - 2000 sq feet floor area.

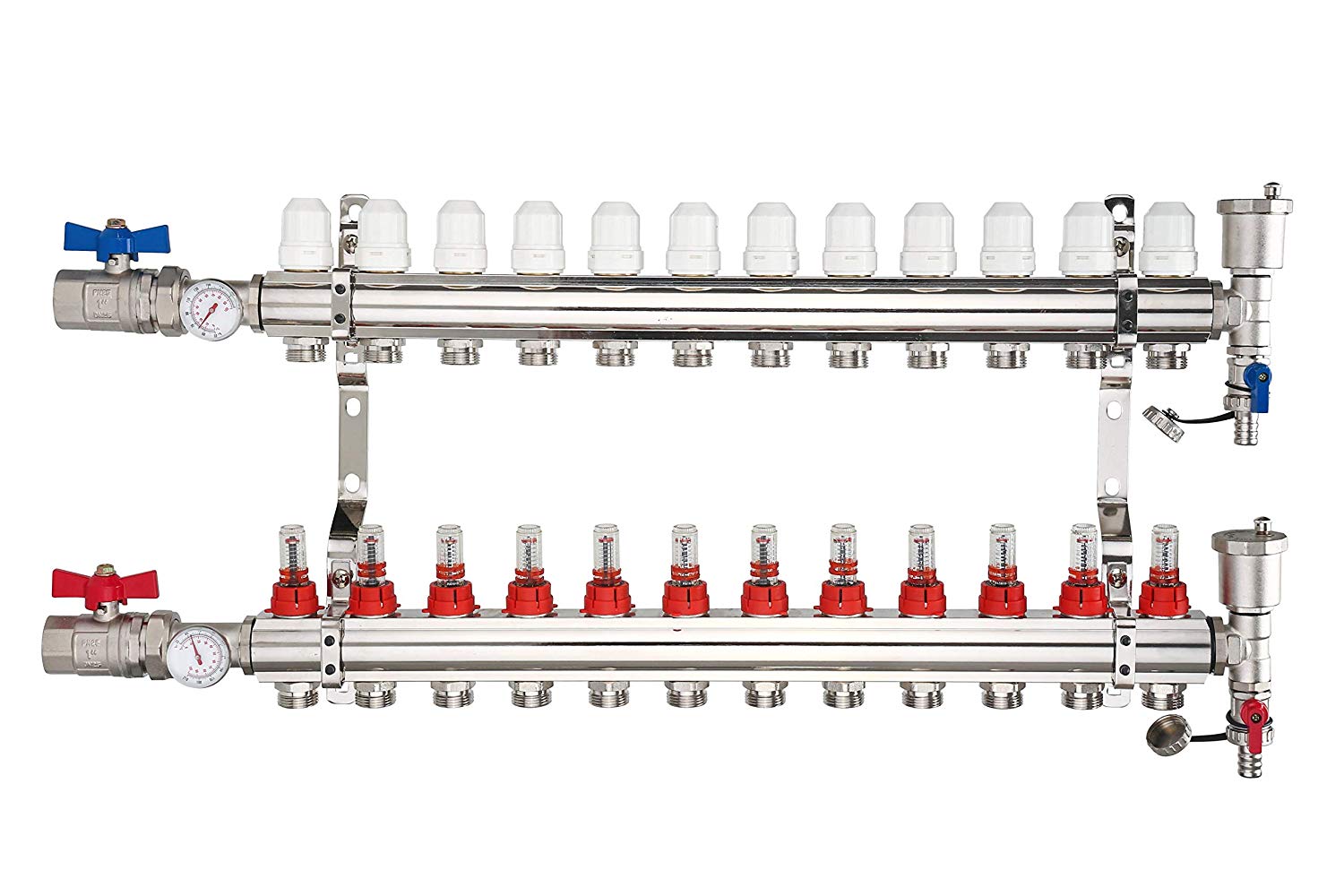

- For the bigger places, Radiant Heat Manifold Brass up to 12 Loop outlets is available. This hydronic heating manifold can warm an area of nearly 2500sq feet.

Installation of WiseWater Alfa Heating Company Manifold

Radiant manifolds are easy to install. The nickeled brass material used for the heating manifold system can be inserted in the plastic pipes easily as compared to the stainless steel one. You can get a heavy stainless steel frame that can be fixed to any wall. This radiant heat manifold comes pre-assembled, which saves time. Only the best Radiant Manifold that passes the pressure test is sold.

To install the hydronic heating manifold, no additional PEX tools are needed. You are required regular pliers to connect the PEX tubing to the Manifold.

- First, fix the Manifold to the bracket.

- Connect the valves.

- Fix the pipes.

- Release the air with an air vent before using your radiant heating manifold, and it is ready to use.

Things to Consider Before Installation

Have a Plan: Before getting started with installation, have a proper plan of where do you want to place your radiant heating manifold. Having a map will be helpful and will guide you on where to place the pipes.

Measure the area: You should have an estimate of the area you want to cover with a hydronic radiant floor manifold before buying and installing. There are different sizes available for Manifold. It influences the pricing of the Manifold and how efficiently heating the Manifold will work for you.

Construction: If your house has big windows, it affects the heat your house absorbs. Consider a professional's help to understand how insulation works.

Budget: Always plan your budget. It will help you to find the best radiant manifolds on a budget without compromising the quality.

Frequently Asked Questions

With Manual valves, you can adjust a radiant heat manifold.

- First, remove the caps of the Supply or Flow tube of the Manifold.

- Then turn the valves anti-clockwise to decrease the flow rate and vice versa to increase the flow rate.

- Adjust each circuit, following these steps, as per your need.