Keep your oil systems efficient and protected with reliable cooling. Explore brazed plate oil coolers built for compact setups and consistent heat exchange. Minimize downtime, control oil temperature, and support long-term system performance with a practical solution that suits your needs.

Maximize Heat Transfer in Limited Space

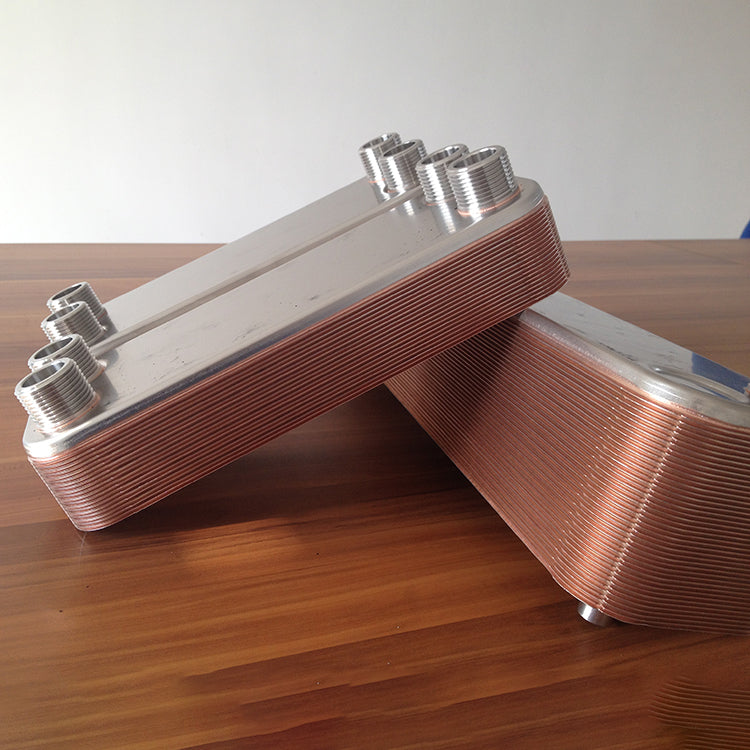

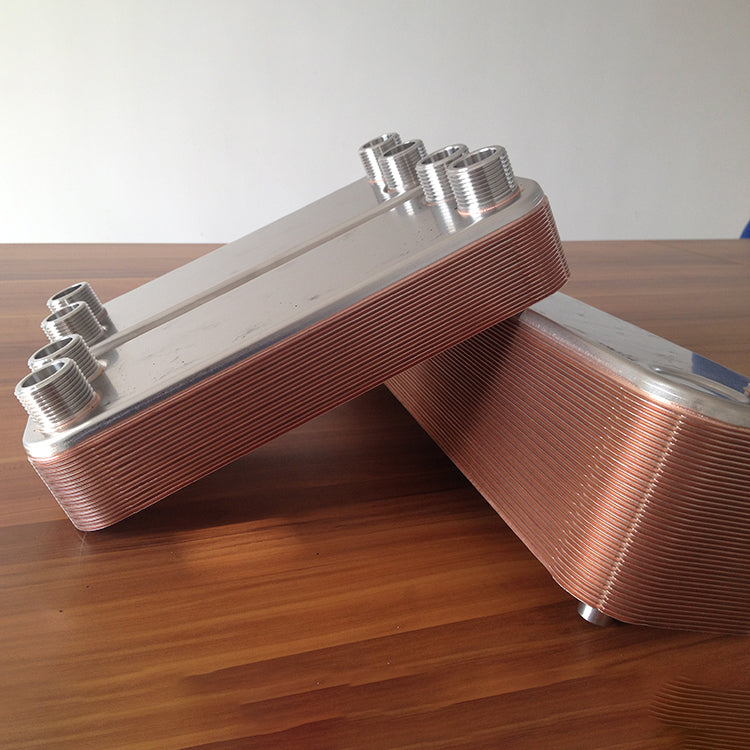

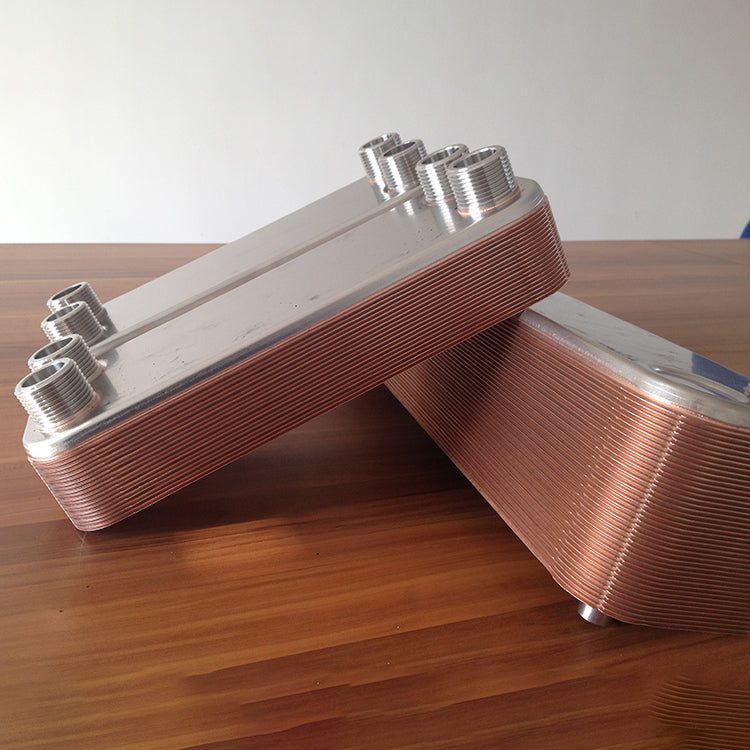

When choosing an oil cooling solution, performance and space often come into conflict. But with a plate oil cooler, you get both. These units offer excellent thermal exchange while maintaining a low footprint. Their multi-plate design increases the surface area, allowing for efficient heat transfer between the oil and cooling water without requiring a bulky structure.

The slim design fits into tighter systems without compromising function. That’s ideal for compact hydraulic, marine, or industrial machinery setups. More efficiency in less space = cleaner installation and better system control. The reduced weight also eases transport and installation.

Their internal channel structure ensures minimal pressure drops while maintaining stable oil temperatures, which helps preserve the performance and durability of nearby components. If you need a compact yet powerful way to manage heat, a plate oil cooler could be the right fit.

Durable Brazed Construction for Demanding Environments

One key factor that sets a brazed cooler apart is its durable, all-metal design. Instead of using gaskets or seals, these heat exchangers are permanently fused using a brazing process. That means fewer failure points and a lower risk of leaks, even under high pressure or thermal cycling.

This makes them especially effective in demanding applications, such as heavy-duty lubrication oil systems or closed-loop hydraulic circuits. The steel plates are tightly bonded to offer greater strength and heat tolerance, critical when dealing with high oil temperatures and fluctuating flow rates.

No gaskets = less maintenance over time. The internal flow paths are also optimized for turbulent flow, enhancing heat transfer and preventing fouling. That results in more efficient cooling and less system downtime.

Looking for a dependable cooling solution that doesn’t need constant attention? A brazed cooler is designed to withstand intense usage without requiring frequent intervention.

Space-Saving Performance Without Compromise

A compact oil unit doesn’t just mean smaller dimensions—it means smarter engineering. These heat exchangers are built to offer high thermal efficiency while using minimal material and space. That’s what makes them a go-to for many industrial setups that can’t afford bulky, complicated equipment.

Their space-saving form factor allows for close integration with other mechanical systems. At the same time, internal flow paths are structured to maximize heat transfer surface area. More efficient heat exchange = better overall system health.

Additionally, their lightweight and sturdy shell enable easier installation and reduced structural requirements. That’s especially useful for mobile systems and tight equipment layouts.

Stable Oil Temperatures for Reliable Equipment Operation

Keeping machinery at the right temperature isn’t just about cooling—it’s about control. A high-quality oil heat exchanger ensures a constant flow of clean, temperature-regulated oil. This matters most when you’re running sensitive equipment that can’t afford thermal fluctuations.

By transferring heat effectively to water or other fluids, these units stabilize oil conditions across all working phases. Better stability = longer-lasting pumps, valves, and bearings. This extends the time between oil changes and reduces the need for repairs.

The result is reduced downtime and increased reliability, especially in operations that run continuously. A well-functioning oil heat exchanger protects your entire system from premature wear and tear.

But how do these units handle the most extreme thermal demands? The answer lies in their flexibility with cooling fluids.

Thermal Versatility for Varied Applications

A thermal oil cooler is built for adaptability. It works with water, glycol, or other cooling liquids to extract heat from oils used in compressors, gearboxes, and hydraulic setups. That flexibility makes it an easy choice for industries with strict operating limits.

Depending on your setup, different sizes and flow rates are available to fine-tune the cooling output. The brazed-plate construction supports high thermal conductivity while maintaining a low overall footprint.

Designed to work across a range of pressures and fluid types, the thermal oil cooler combines resilience with performance. It’s ideal for installations that operate under varying loads or where oil quality must be maintained over extended periods.

Let’s wrap it up with a few practical points to help you choose the right model.

Choose the Right Solution for Your System

Not every system requires the same cooling capacity, but all benefit from stable oil temperatures. That’s why we offer multiple sizes of plate oil cooler units to match your flow and temperature range. From small equipment to large-scale systems, our models are built for integration and durability.

Here’s what to consider:

- Oil flow rate and operating temperature

- Cooling fluid type (water, glycol, or blends)

- Pressure limits and port dimensions

Each compact oil unit is engineered to perform with minimal maintenance and long service life. Combined with a brazed cooler design, it ensures stable and efficient thermal regulation for your system. And with their wide compatibility, these coolers make upgrading or replacing components easier than ever.

Your equipment’s health starts with temperature control. A high-quality oil heat exchanger or thermal oil cooler is a small investment that can deliver significant performance benefits.