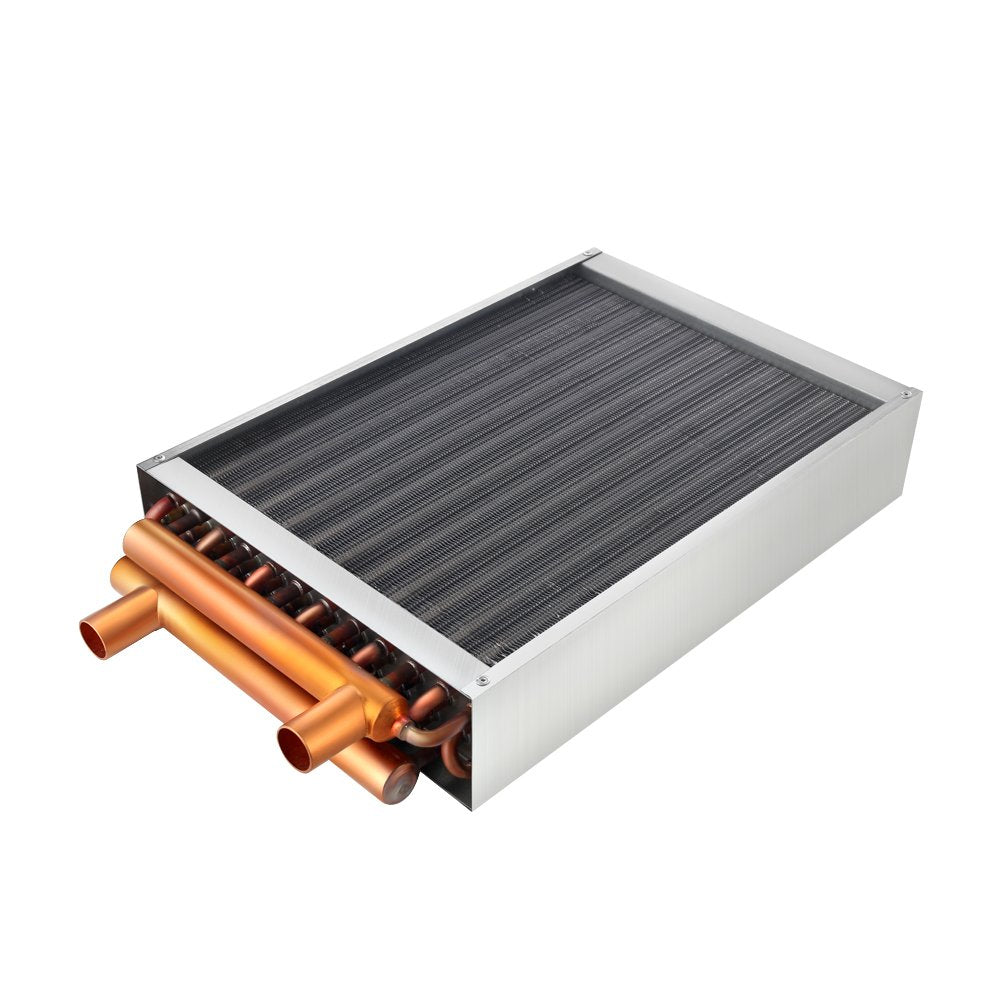

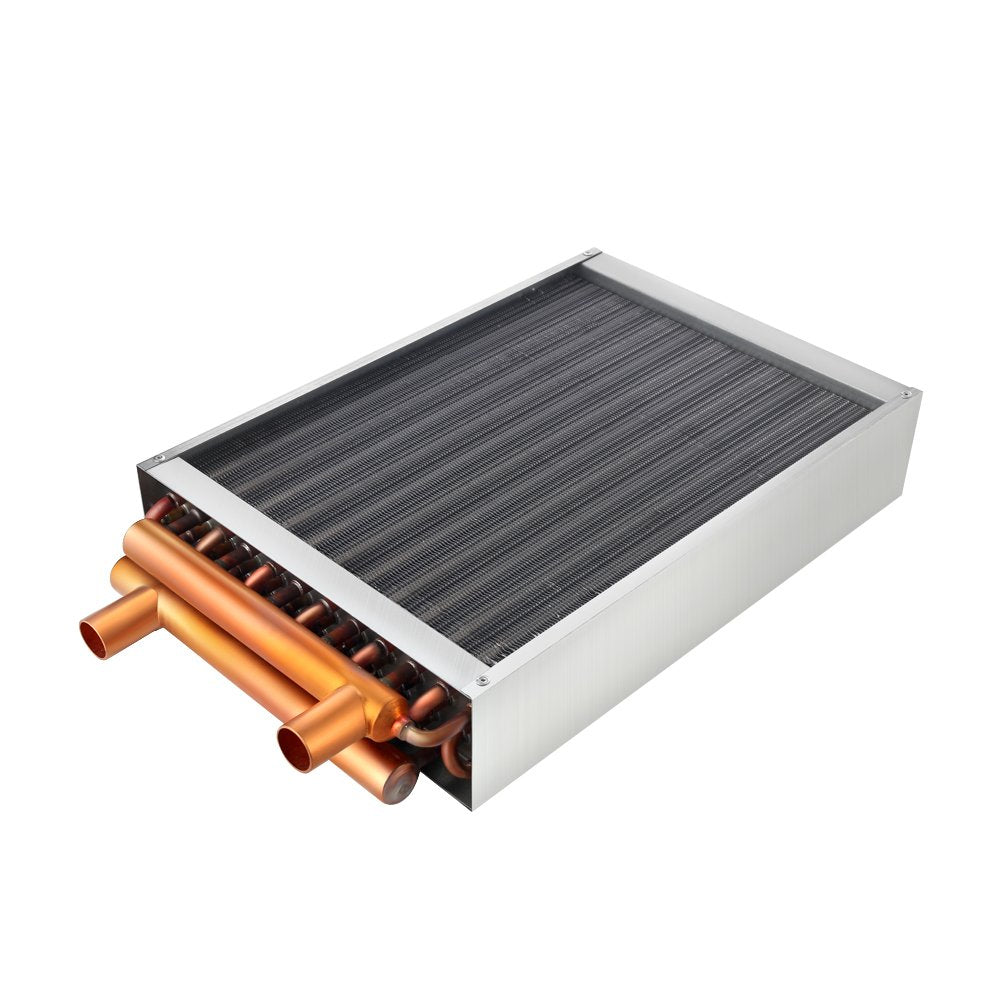

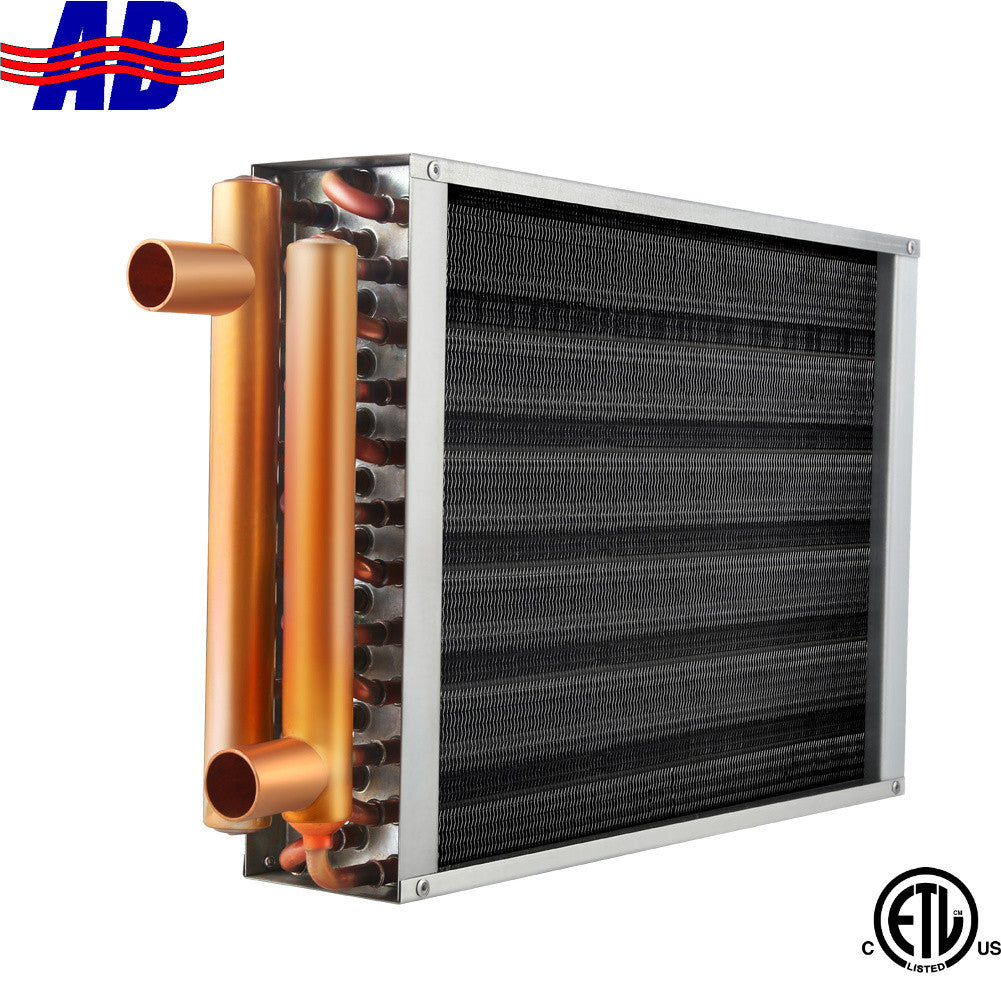

ALFA uses aluminum for fin material for higher heat conductivity. Fin density is an impressive 12 fins per inch. This unique design allows for heating loads of 50,000 to 60,000 Btu per square foot. Even though the fin density is high, the flow resistance through the coils is surprisingly low. Consists of 1 supply and 1 return copper manifolds with smaller diameter copper tube coils running from side to side on the heat exchanger. The tube coils are accompanied by aluminum fins, which purpose is to maximize heat transfer between water and air mediums. The structure is encased in a metal frame to reinforce the construction of the air to water heat exchanger. As hot water or other suitable solution enters the supply manifold of the water to air heat exchanger, it is separated into the tube coils, which carry it throughout the heat exchanger to the return heat exchanger. The process is similar with cold water or other cooling liquid when the heat exchanger is used for cooling applications.

All ALFA heat exchangers go though a strict quality control and a high pressure leak test to assure quality and long-lasting performance.

FAQ

An air-to-water heat exchanger is a compact, highly efficient device used to transfer thermal energy between air and water systems. These units are commonly installed in HVAC setups, boilers, wood furnaces, or any system where heat needs to move from a water-based source to air — or vice versa. ALFA’s models are built using 3/8” copper tubes paired with high-density aluminum fins, creating a powerful combination that maximizes heat transfer while minimizing size and resistance.

These heat exchangers are especially useful in residential and public building installations due to their lightweight design, metal-encased structure, and high thermal output. With performance ranging up to 240,000 Btu, they deliver reliable heating or cooling in a variety of system types.

The fin structure matters. A 12 fins-per-inch density means more surface contact between air and the water-carrying coils. More contact = more heat transfer and better efficiency. Even at high performance levels, these units maintain low flow resistance, which helps keep operation steady without straining pumps or blowers.

Suppose you’re working with an outdoor boiler, an indoor wood furnace, or planning to integrate liquid cooling into your HVAC setup. In that case, these exchangers are made for seamless connection and strong thermal performance.

The process is surprisingly straightforward. Hot or cold water flows into the supply manifold, entering the copper coils inside the exchanger. These coils are surrounded by aluminum fins that rapidly absorb and release thermal energy. As air passes over the finned surface, it picks up heat (or loses it), depending on the temperature of the water inside the tubes.

Every unit contains one supply and one return copper manifold. Inside, multiple parallel coils allow the water to spread out evenly, maximizing the contact area. That’s where the aluminum fins step in — boosting heat exchange by creating more surface for interaction between the flowing air and the heated (or chilled) water.

It’s not just for heating. The same design works in reverse for cooling, provided the system is paired with a chilled water source. Cooling capacity and heating capacity are both dictated by flow rate, fin design, and temperature differences — all optimized in ALFA’s selection of exchangers.

High fin density = efficient energy transfer in both directions. This simple mechanism delivers powerful results without requiring any moving parts, making these units durable and low-maintenance.

Yes, you can — and in many cases, it’s the most efficient option. If you’re using a boiler, outdoor wood furnace, or any system that circulates heated water, these exchangers can easily be integrated with your forced air HVAC system. ALFA’s units are designed to slide into existing ductwork, usually mounted in front of the air handler or blower, allowing heated or cooled water to regulate the air temperature in your entire home.

This approach offers better temperature control and more flexibility compared to some traditional electric-only systems. You’ll also benefit from:

- Lower running costs when paired with high-efficiency boilers or alternative energy sources

- Compact sizing that fits into tight mechanical spaces

- High Btu output without the bulk of older technology

Before installing, it’s important to size your unit correctly. Bigger isn’t always better. Instead, match the exchanger size to your blower capacity and water temperature. Most ALFA models range from 12” x 12” to 22” x 24”, covering a broad range of airflow and heating demands.

Related Heat Exchangers

- Water to Air Heat Exchangers

- Water to Water Heat Exchangers

- Plate Heat Exchangers

- Plate Heat Exchangers (Copper Brazed)

- Brazed Plate Heat Exchangers

- Brazed Plate Condenser

- Shell and Tube Heat Exchangers

- Side Arm Heat Exchangers

- Swimming Pool Heat Exchangers

- Pool Heat Exchangers

- Marine Heat Exchanger

- Electrical Heat Exchangers