How Sanitary Heating Systems Maintain Clean Environments

Heating is crucial for keeping environments clean and safe. Sanitary heating systems help regulate temperature without introducing contaminants, making them essential for hospitals, laboratories, and food production areas. These systems prevent the buildup of excess moisture, which can create an environment for bacteria or mold growth. Proper temperature control also ensures that sensitive materials, such as pharmaceuticals and medical supplies, remain in optimal condition.

Well-designed sanitary heating systems use corrosion-resistant materials and energy-efficient components to reduce maintenance and operational costs. They are built to comply with strict hygiene regulations, ensuring they do not introduce unwanted particles into the air. Many industries rely on them to maintain stable indoor temperatures without compromising safety.

- Helps control humidity and prevents bacteria growth

- Improves air quality in healthcare and food production

- Uses durable, easy-to-clean materials to maintain hygiene

- Reduces maintenance and operational costs over time

The Importance of Hygienic Cooling Solutions

Cooling systems are necessary for industries where temperature-sensitive materials and equipment must be protected. Hygienic cooling solutions ensure stable climate conditions in hospitals, pharmaceutical production, and research laboratories. These systems prevent temperature fluctuations that could damage stored medicines, biological samples, or sensitive electronic devices.

Maintaining proper cooling also helps control air circulation, reducing the spread of contaminants. With modern filtration and airflow management, hygienic cooling solutions keep indoor spaces clean and comfortable. They are often equipped with energy-efficient components that lower operational costs while ensuring long-term reliability.

- Keeps temperature-sensitive equipment and materials safe

- Reduces the spread of contaminants in controlled environments

- Supports air circulation to maintain clean indoor air

- Uses efficient cooling methods to lower energy costs

The Role of Cleanroom HVAC Technology in Critical Industries

Industries that require strict air quality standards, such as electronics manufacturing and pharmaceuticals, depend on cleanroom HVAC technology to maintain controlled environments. These systems filter air and regulate humidity, preventing particles from interfering with sensitive processes. Cleanroom HVAC solutions use advanced filtration systems, such as HEPA filters, to remove dust, bacteria, and other contaminants from the air.

A well-designed cleanroom HVAC technology setup includes sealed ductwork, controlled ventilation, and specialized air handling units. These components work together to stabilize air quality, ensuring compliance with hygiene regulations. Clean air reduces the risk of defects in high-precision manufacturing and protects research samples from contamination.

- Removes airborne particles that could interfere with production

- Maintains stable temperature and humidity for sensitive materials

- Meets regulatory requirements for cleanroom environments

- Ensures long-term reliability with minimal maintenance

How Sterile Environment Temperature Control Supports Safety

In hospitals and laboratories, sterile environment temperature control is critical to maintaining a clean and safe space. Temperature fluctuations can affect the performance of medical equipment, the stability of stored samples, and the comfort of patients and staff. Proper climate control ensures these environments remain within safe temperature and humidity ranges.

These systems also help reduce the risk of airborne infections by managing airflow and preventing stagnant air pockets. Sterile environment temperature control solutions often include advanced ventilation and filtration to clean the air. Healthcare facilities can improve patient care and operational efficiency with precise climate management.

- Keeps medical equipment and samples at safe temperatures

- Improves patient comfort in hospitals and clinics

- Controls airflow to prevent contamination

- Uses efficient ventilation to maintain clean air

HVAC Systems Designed for Medical and Cleanroom Applications

Healthcare and pharmaceutical industries rely on medical facility HVAC systems to ensure a safe, regulated indoor climate. These systems use specialized air filtration and humidity control to prevent contamination in operating rooms, laboratories, and clean production areas. Proper ventilation reduces the spread of airborne particles and maintains sterile conditions.

Efficient medical facility HVAC systems support hospitals by improving air circulation and patient comfort. By using advanced controls, these systems maintain a consistent indoor climate while reducing energy costs. Hospitals and cleanroom facilities benefit from reliable HVAC solutions that ensure compliance with industry standards and improve safety.

- Regulates air quality in medical and pharmaceutical facilities

- Reduces contamination risks in clean environments

- Provides precise temperature and humidity control

- Supports energy efficiency and cost savings

For industries that demand the highest standards in hygiene—such as food, beverage, and dairy production—sanitary heating and cooling equipment isn’t optional. It’s a fundamental part of maintaining safe, controlled environments where contamination can’t be allowed. Choosing the right supplier means getting equipment that meets strict regulatory expectations without sacrificing performance.

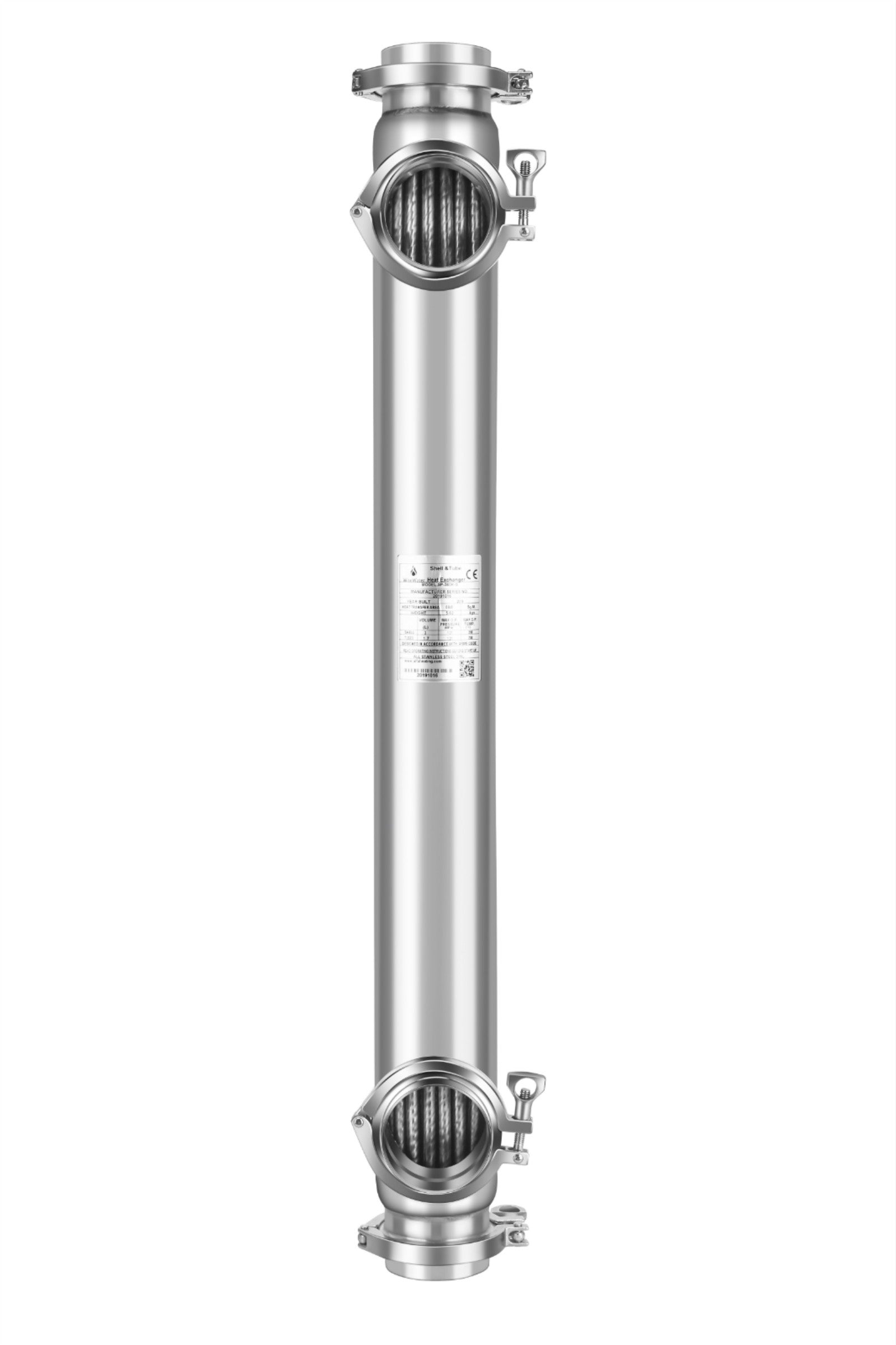

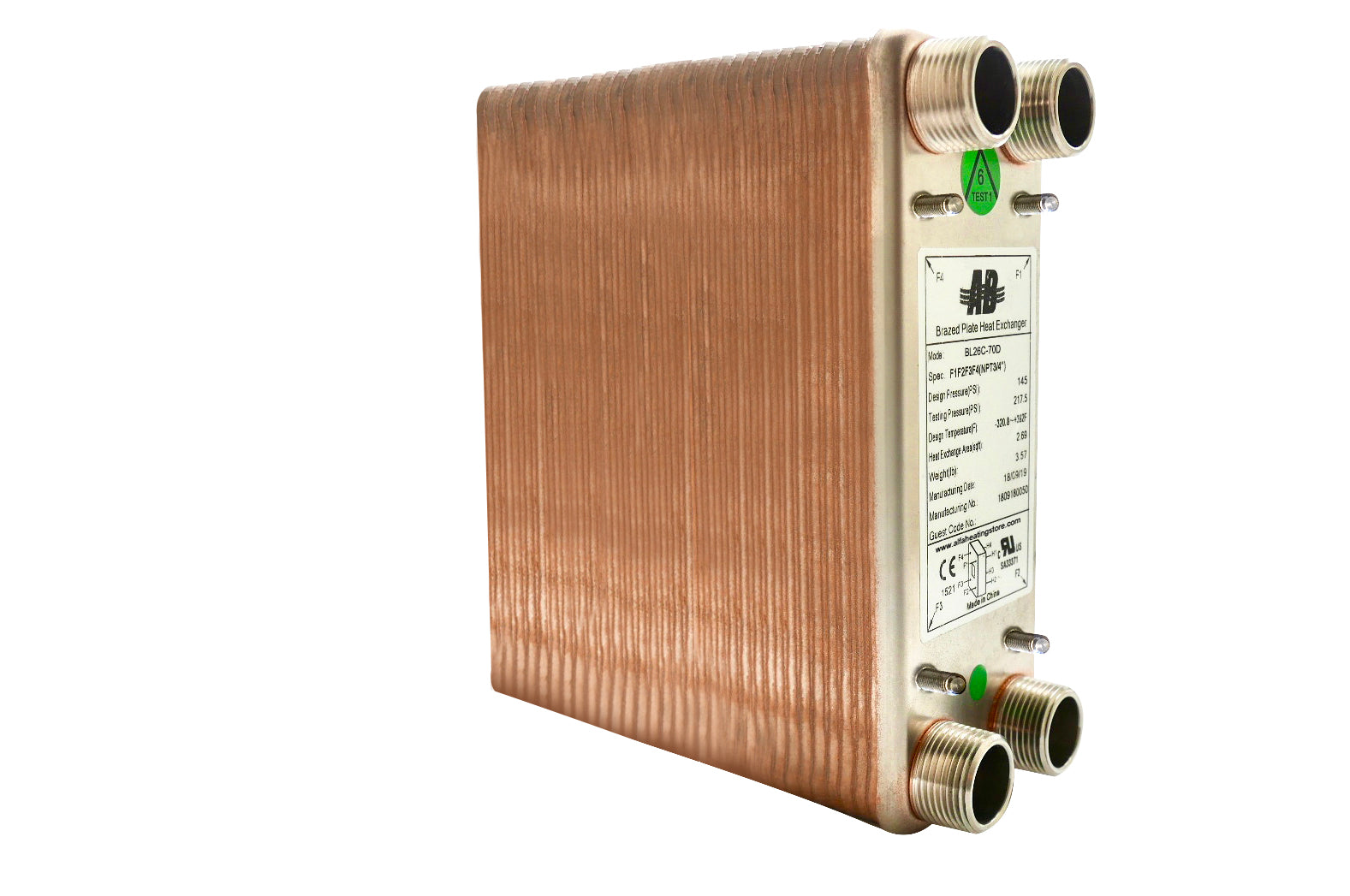

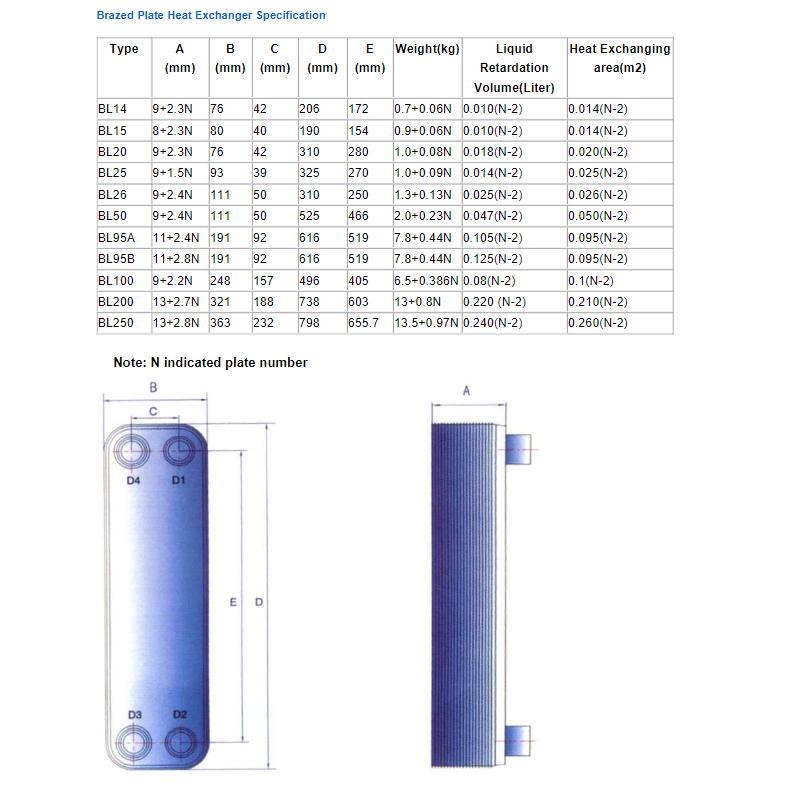

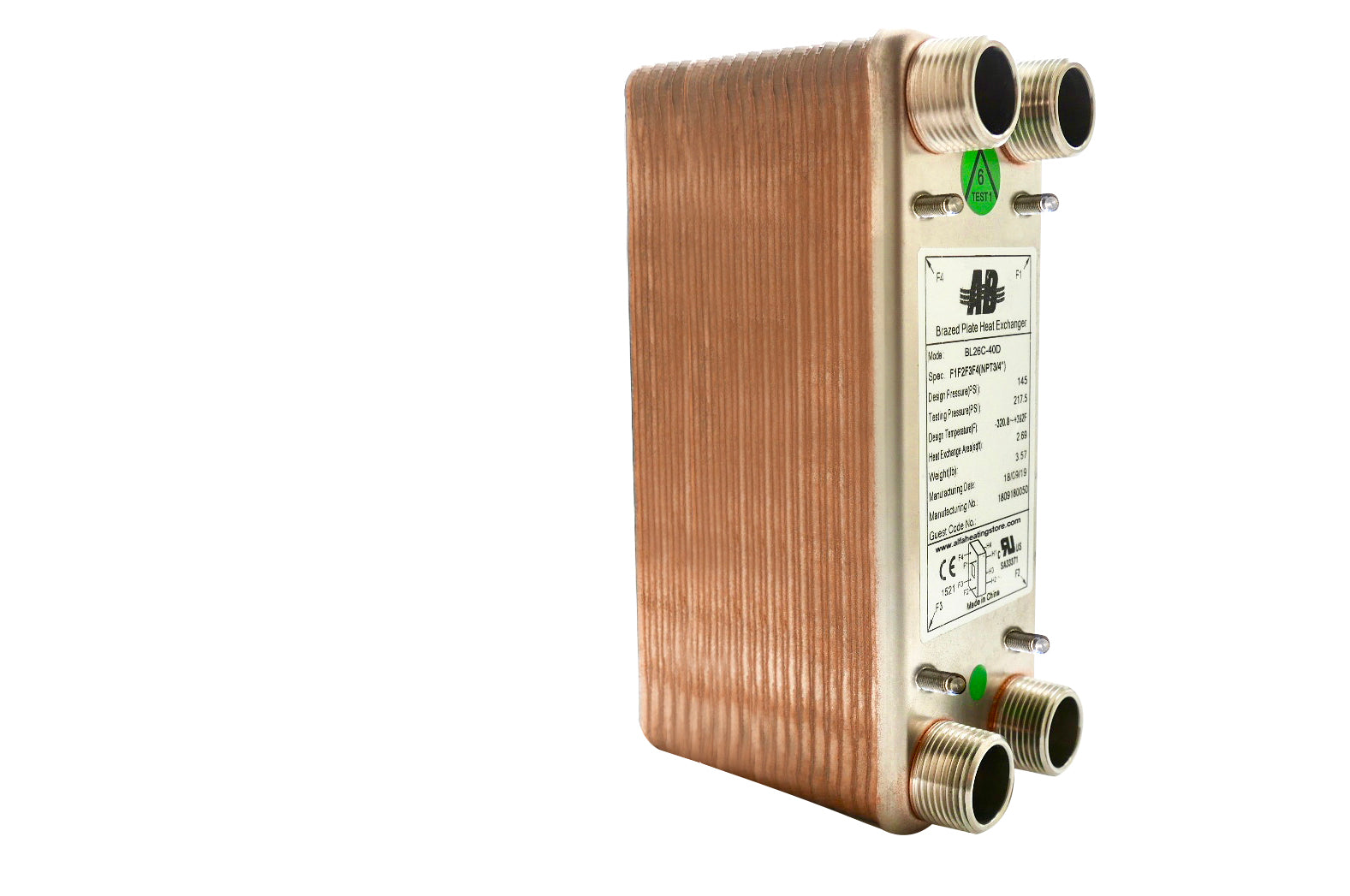

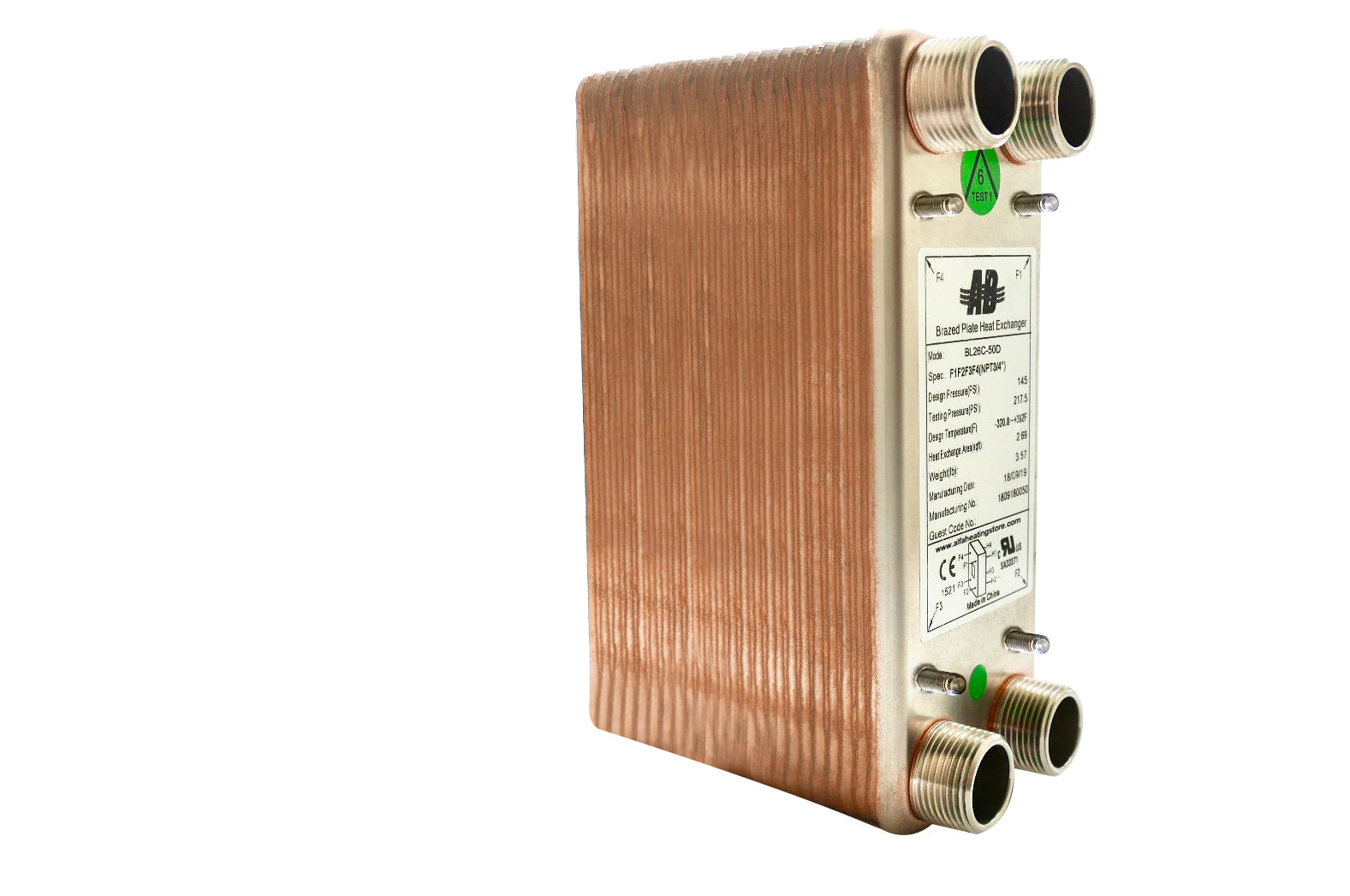

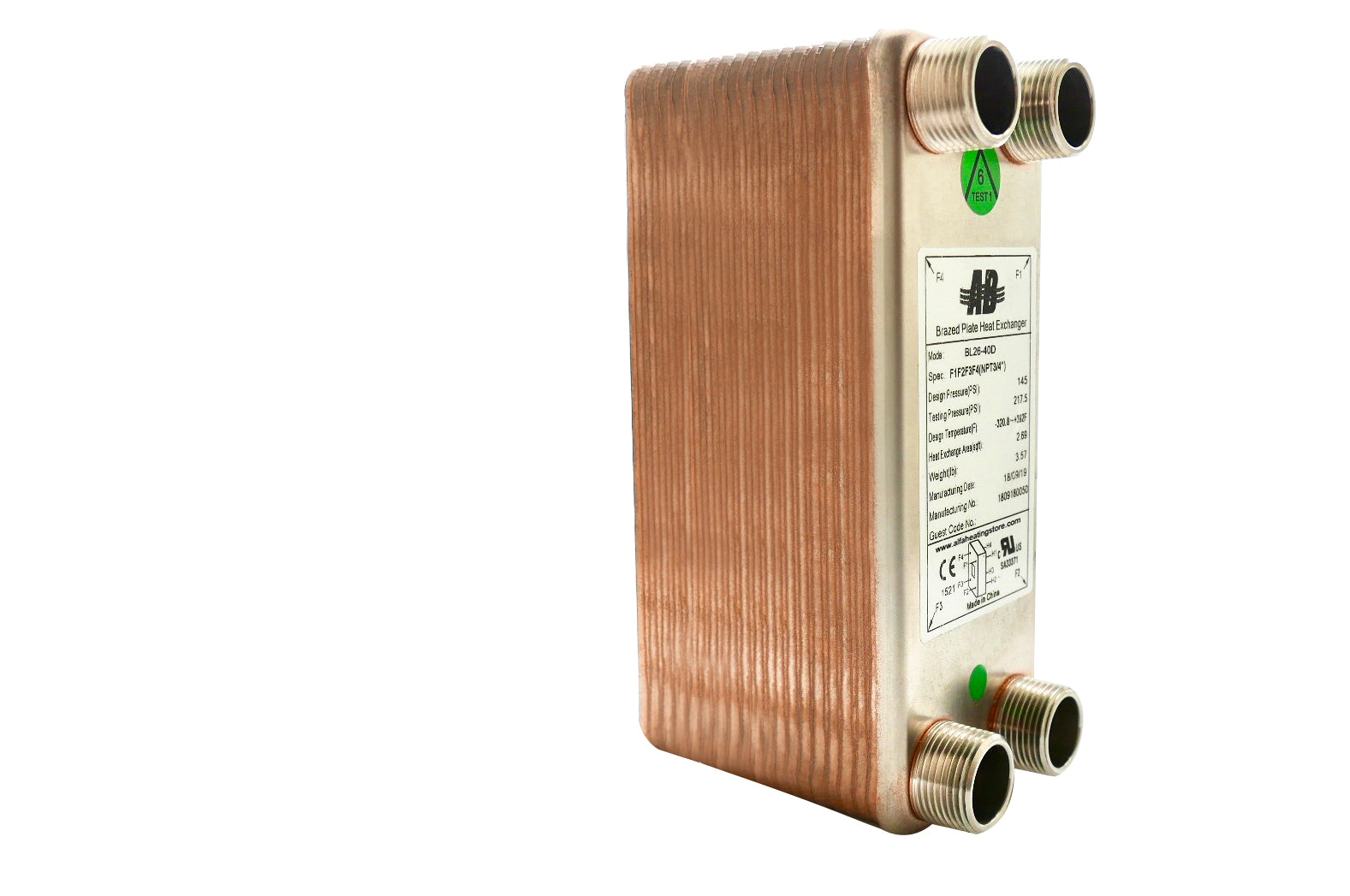

Alfa Heating offers a specialized range of sanitary heat exchangers designed specifically for hygienic processing. With an online collection that includes stainless steel shell-and-tube models and brazed-plate heat exchangers in multiple sizes, the product range supports operations ranging from small-scale to full-scale production.

Purchasing from Alfa Heating also means access to technical support and a streamlined ordering process. Each product is designed using corrosion-resistant materials like SS316L, paired with tri-clamp fittings for easy cleaning and maintenance. These details are essential for complying with industry standards while minimizing downtime.

Local suppliers may offer limited selection or off-the-shelf options, but Alfa Heating provides customizable configurations and consistently high build quality, making it suitable for both new installations and replacements. Orders can be placed directly through the website, where product specifications are clearly listed. For custom builds or large-scale orders, Alfa also provides consultation support to help determine the best solution for your application.

In environments where cleanliness is non-negotiable, not all heat exchangers are equal. The best sanitary heat exchangers combine efficient thermal transfer with design features that support easy maintenance and full system hygiene. Alfa Heating focuses on both.

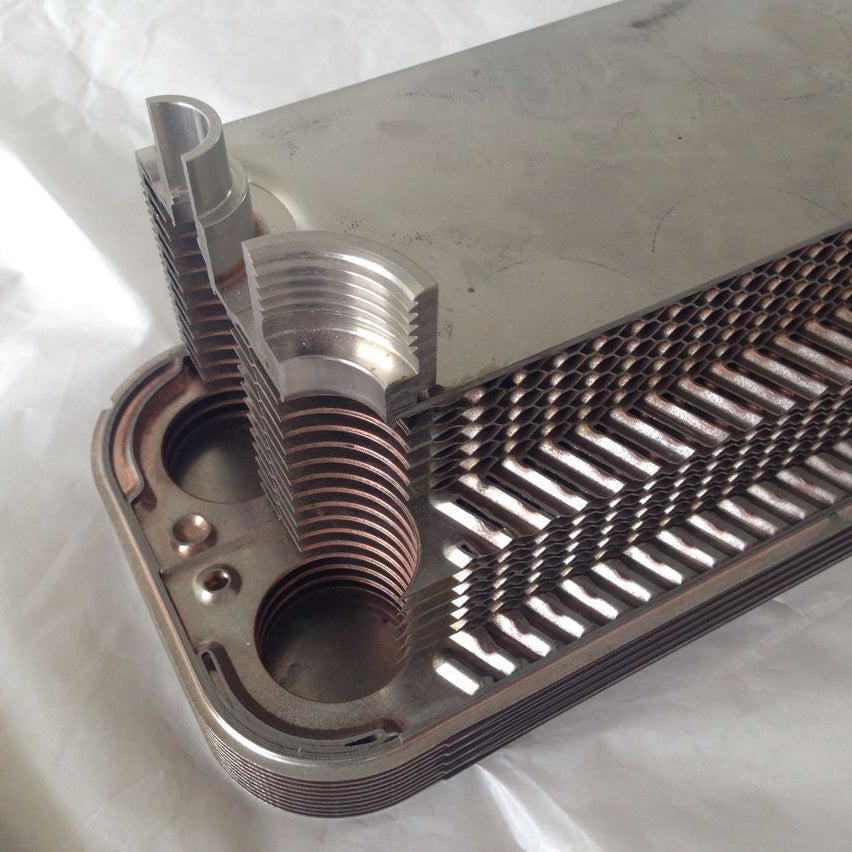

Shell-and-tube models with tri-clamp ends offer seamless integration with clean-in-place (CIP) systems, making them an excellent fit for food, dairy, and pharmaceutical applications. Their internal flow design minimizes pressure drops while supporting smooth product transfer. More importantly, all internal surfaces are fabricated from polished stainless steel to prevent microbial buildup.

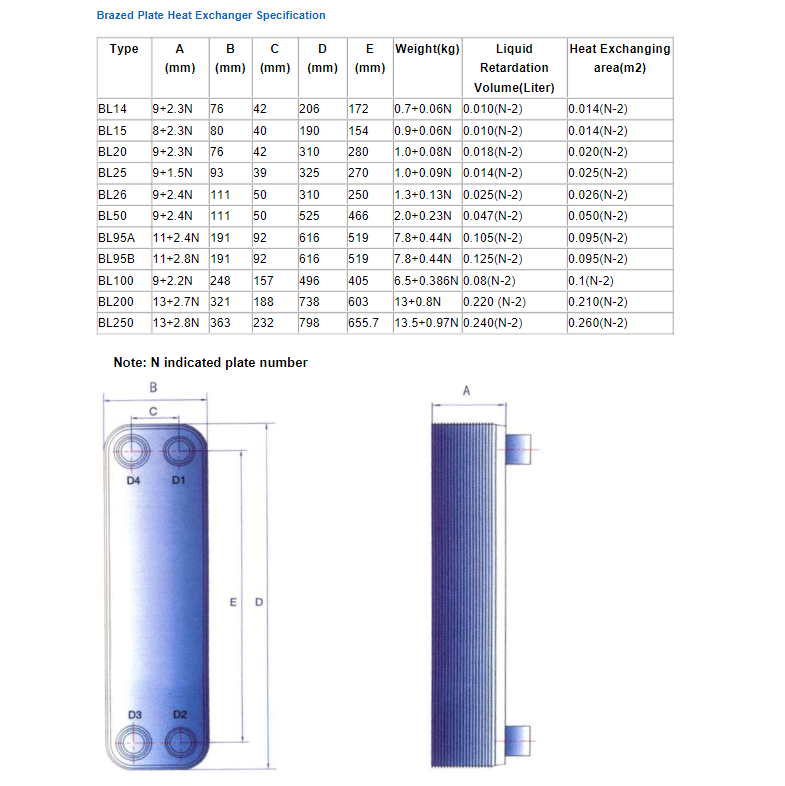

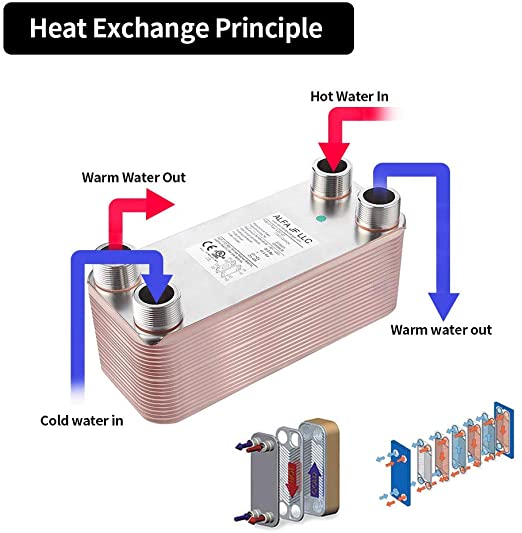

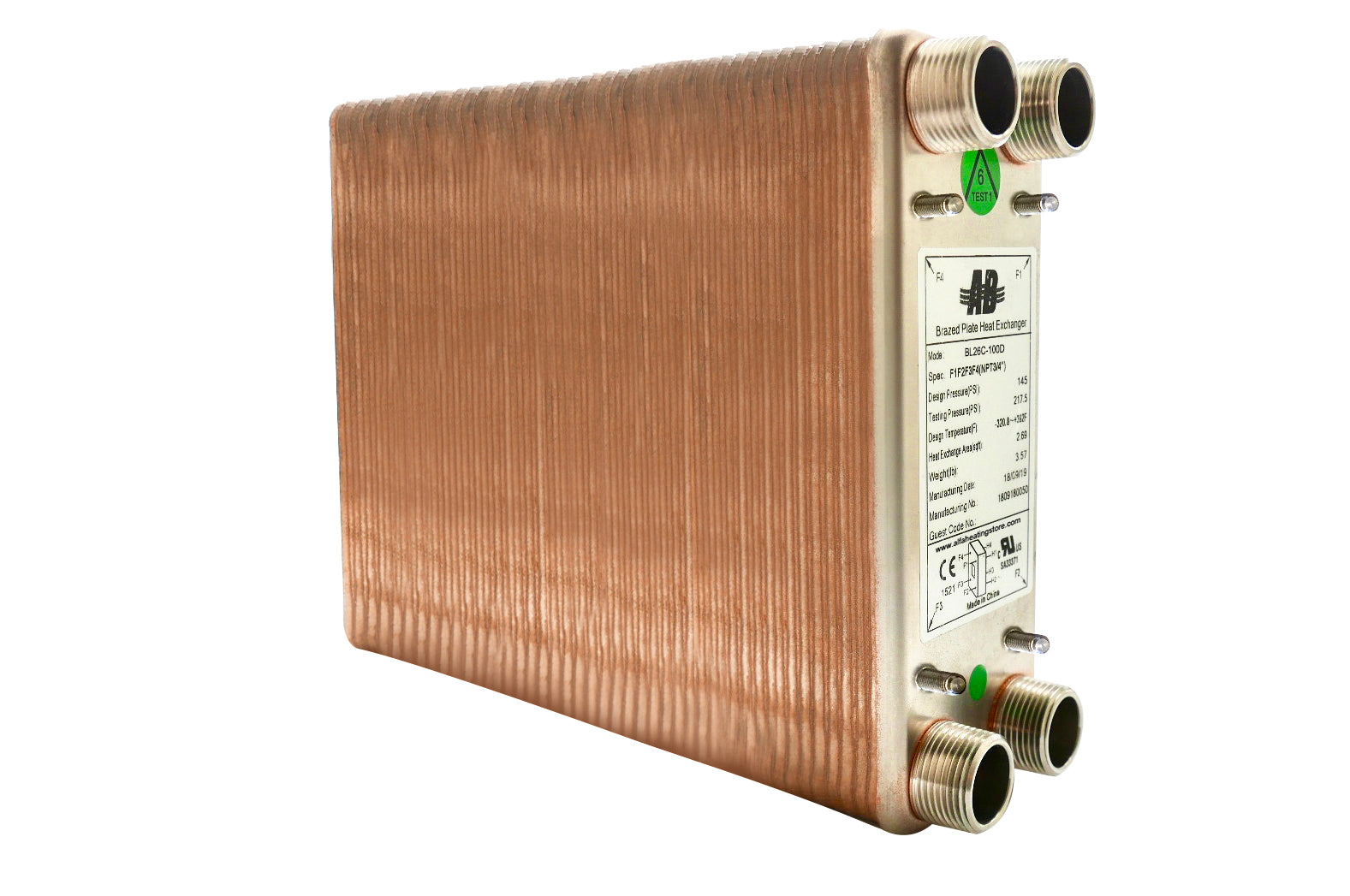

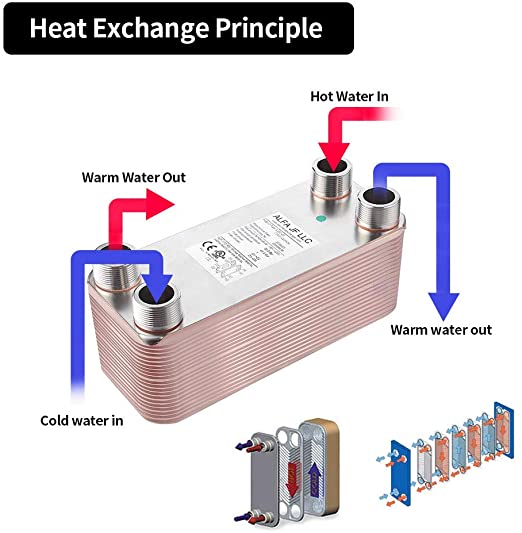

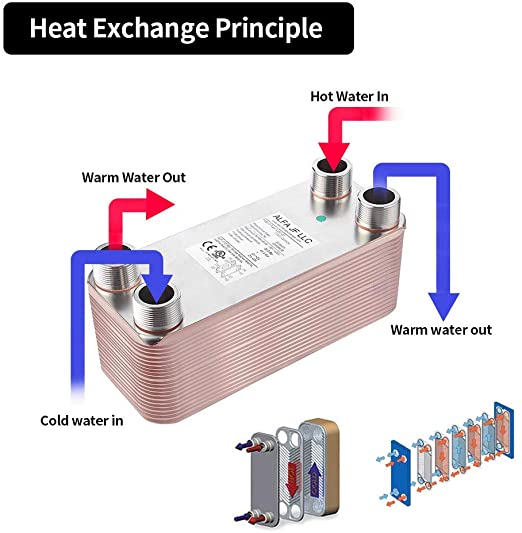

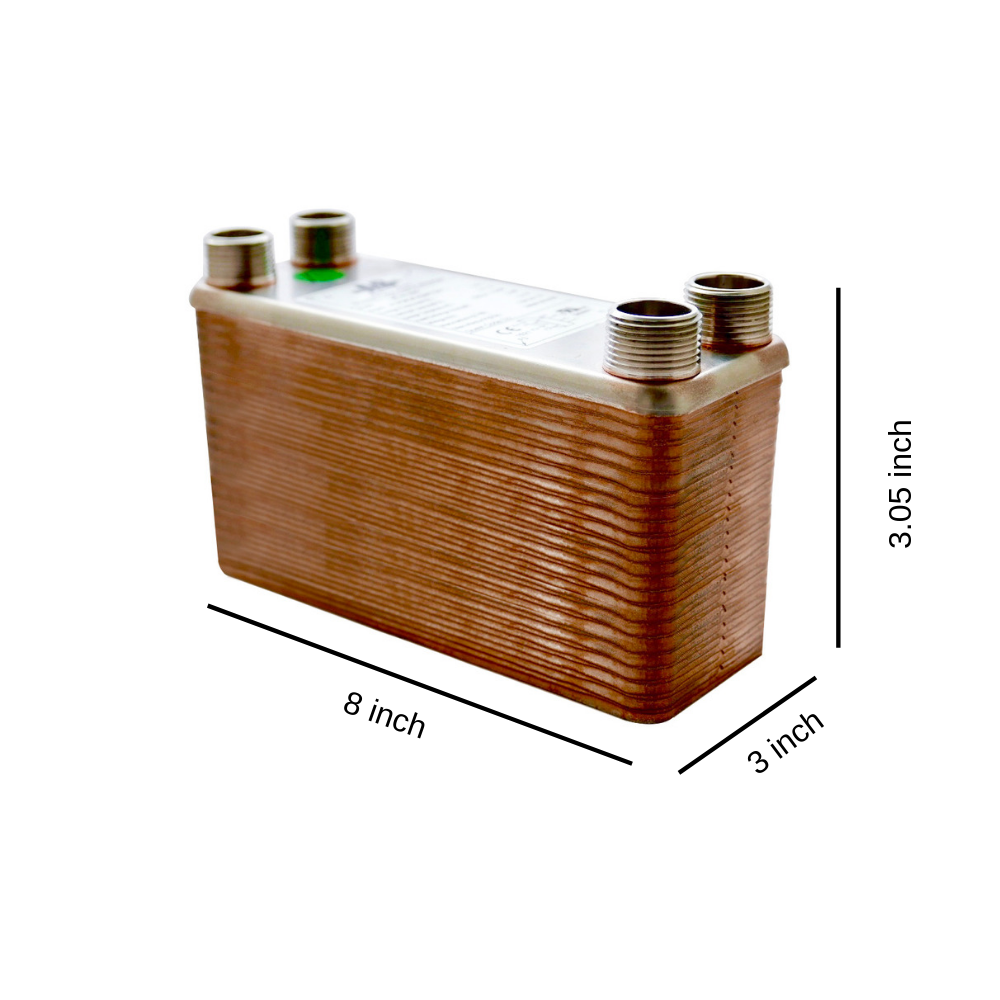

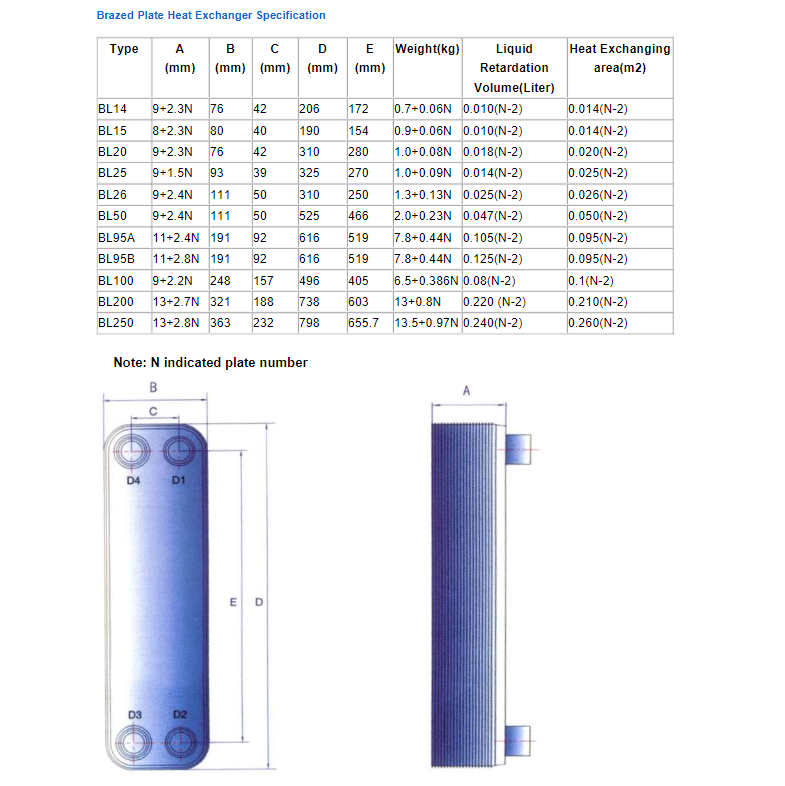

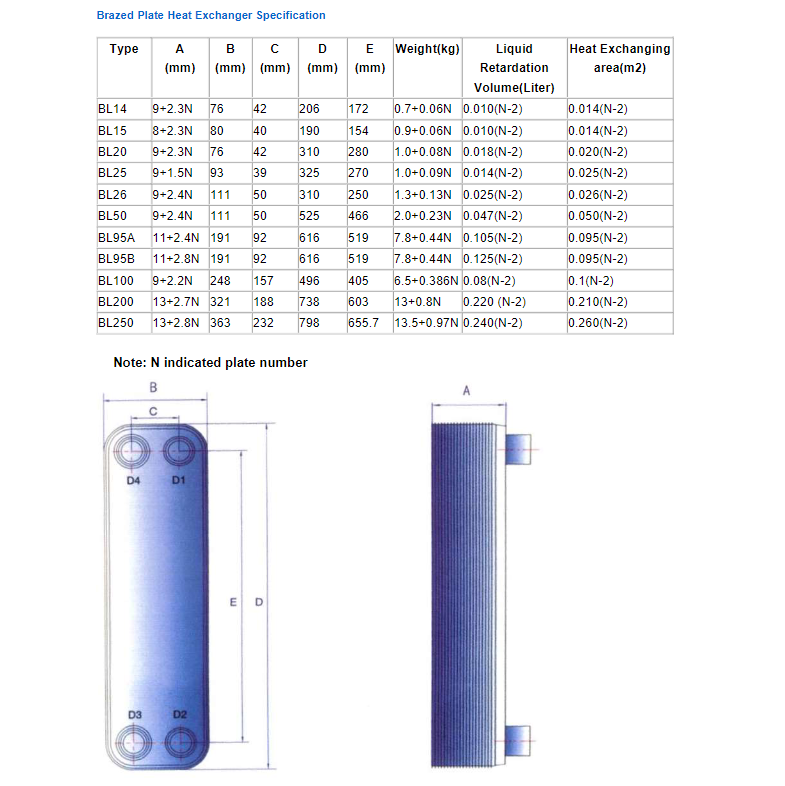

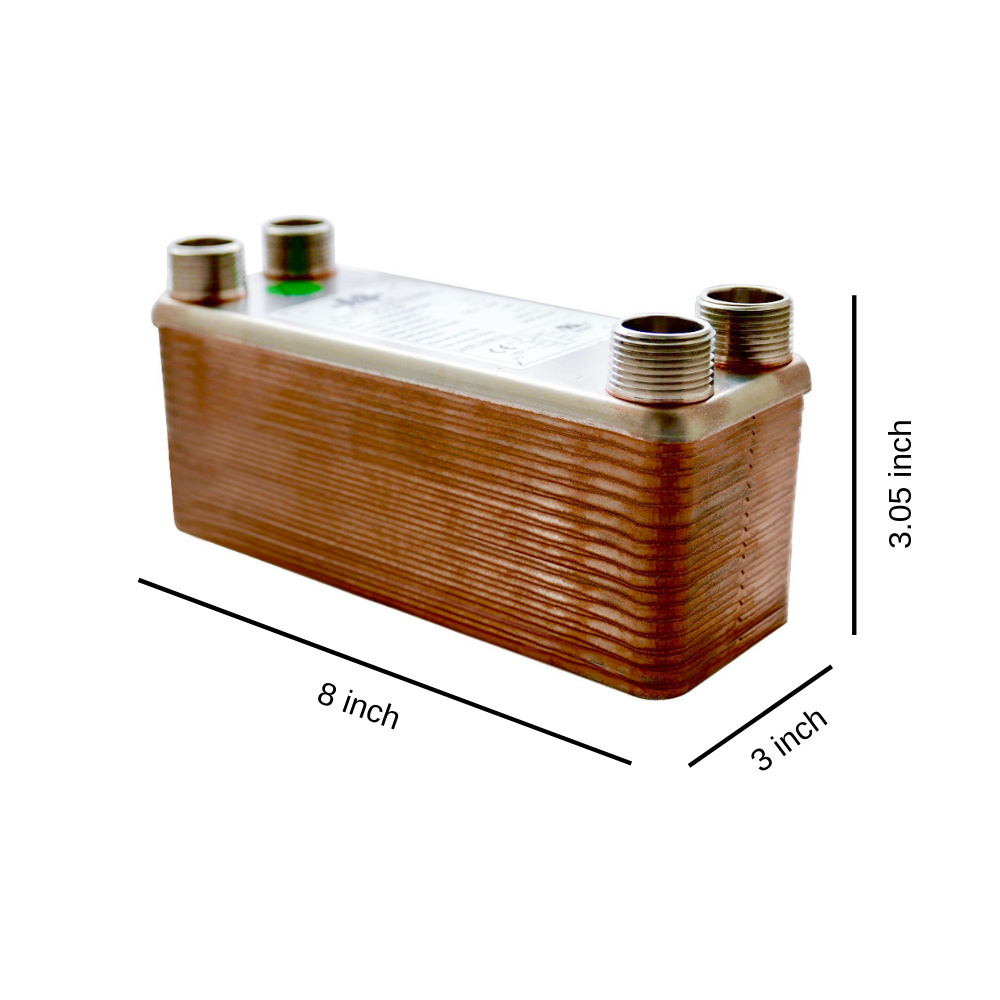

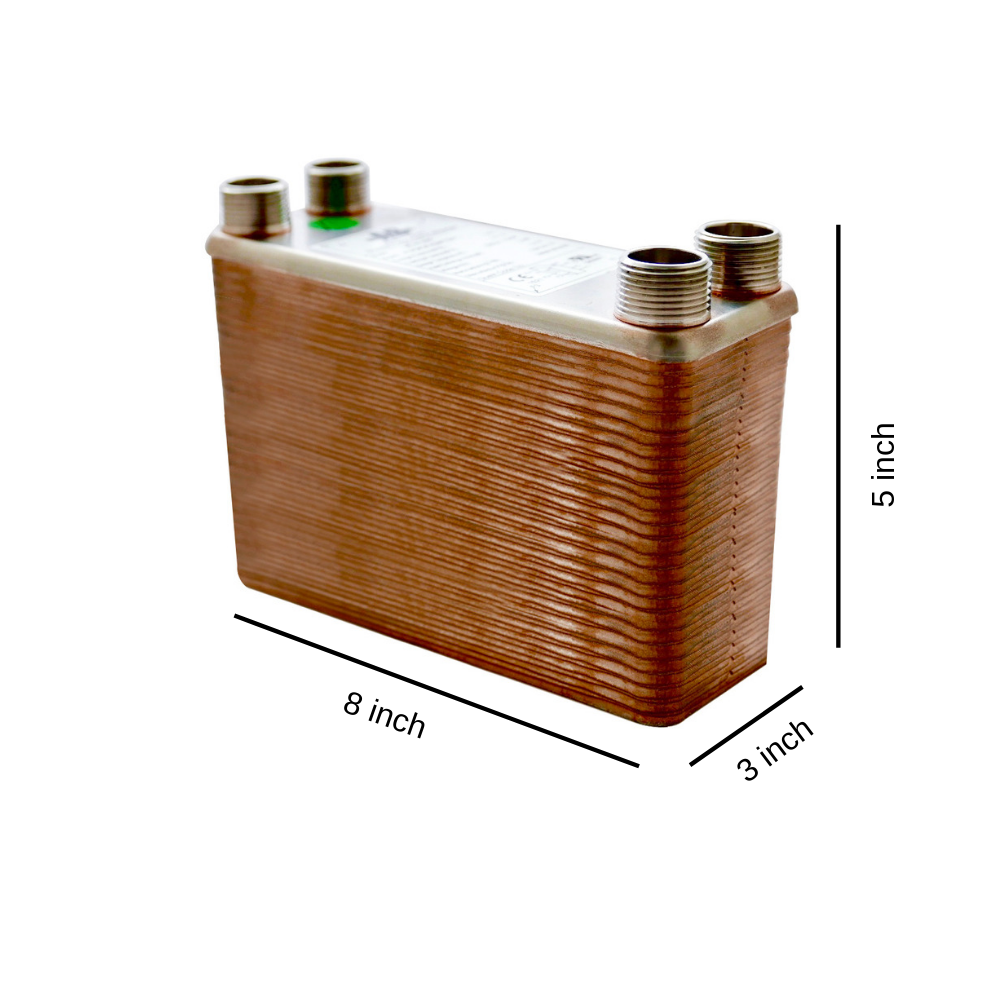

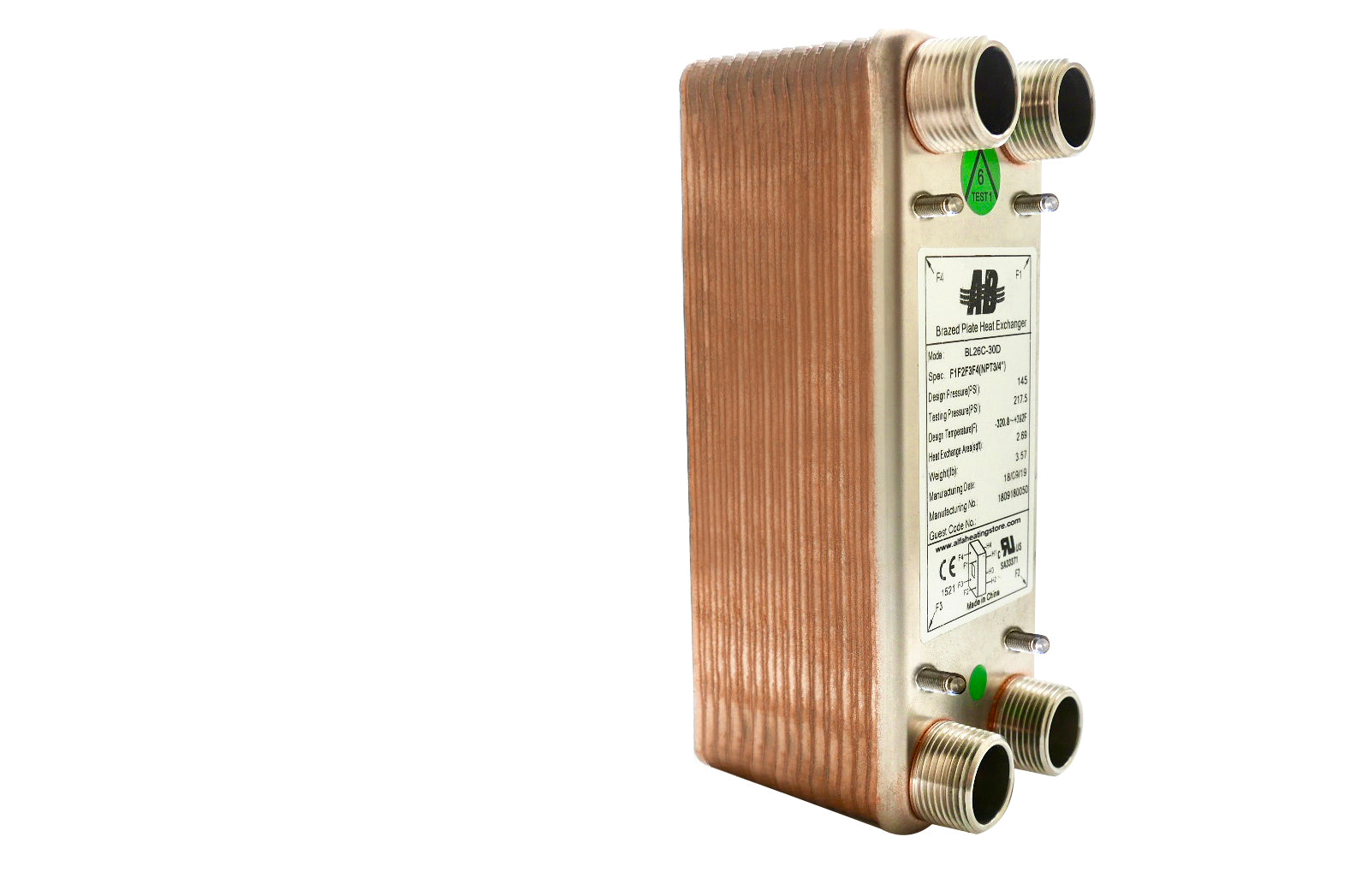

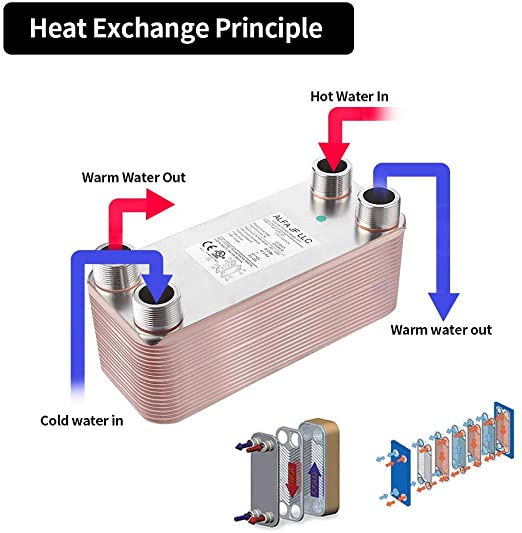

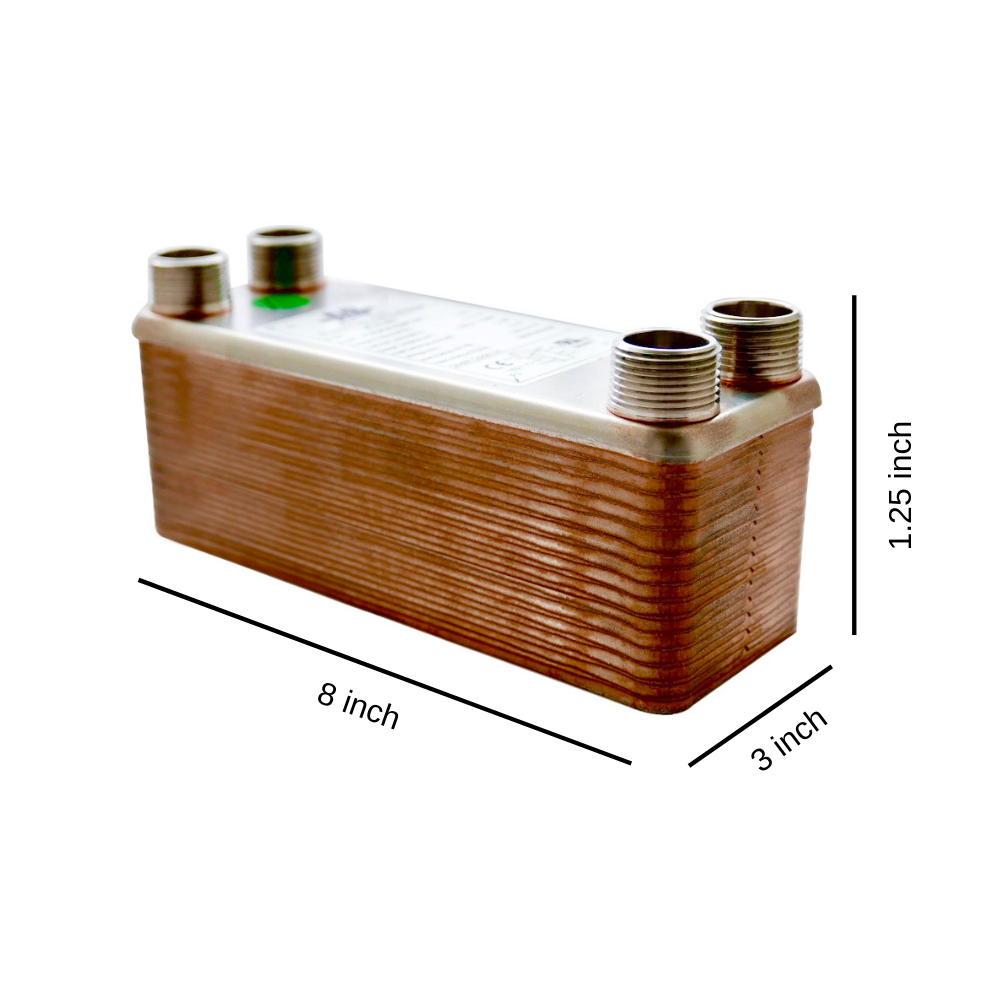

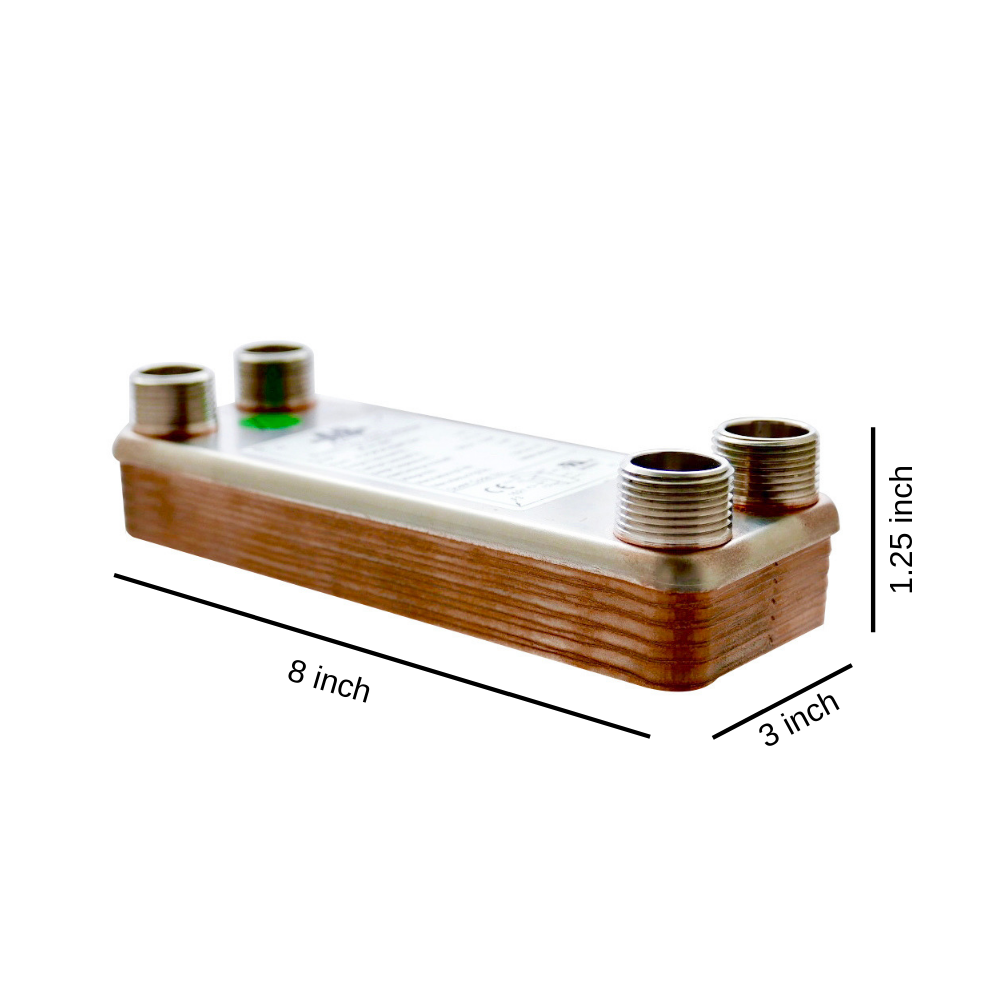

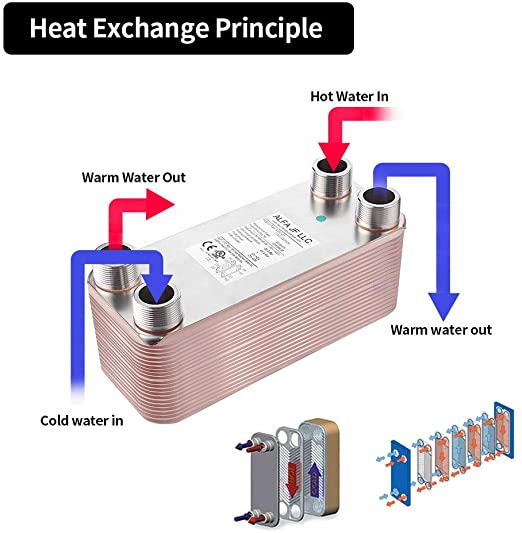

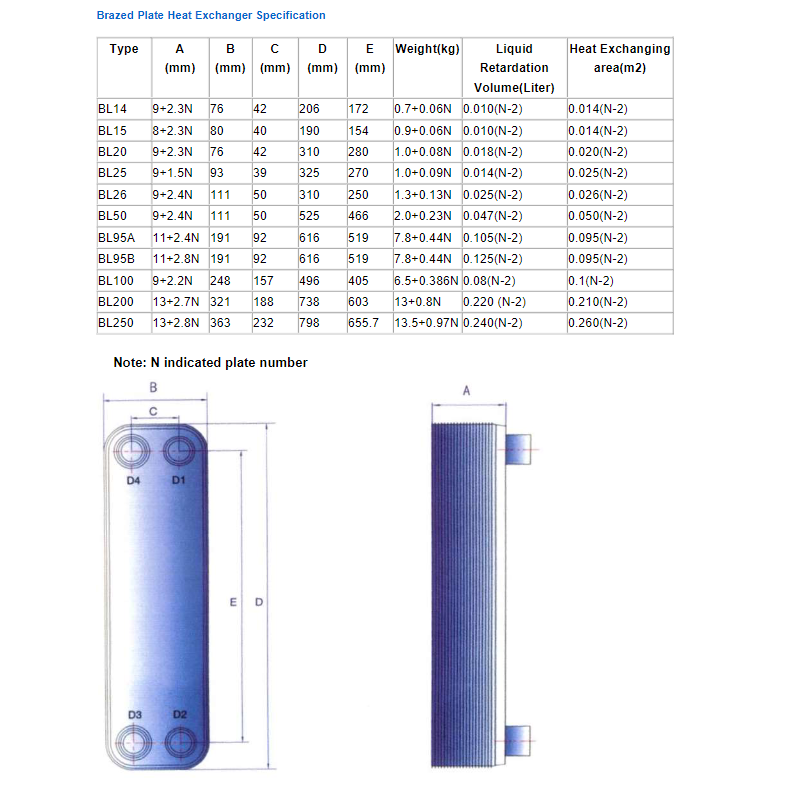

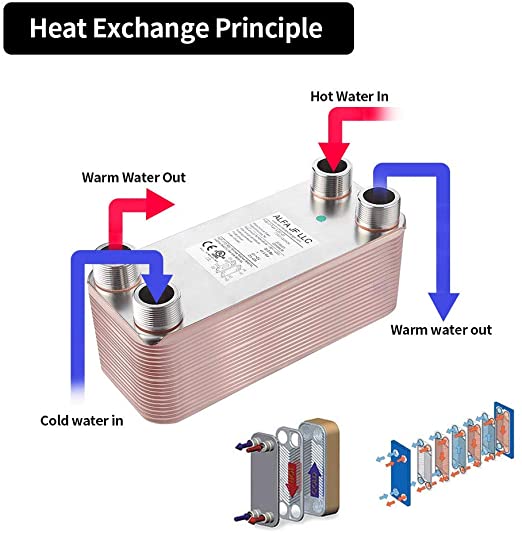

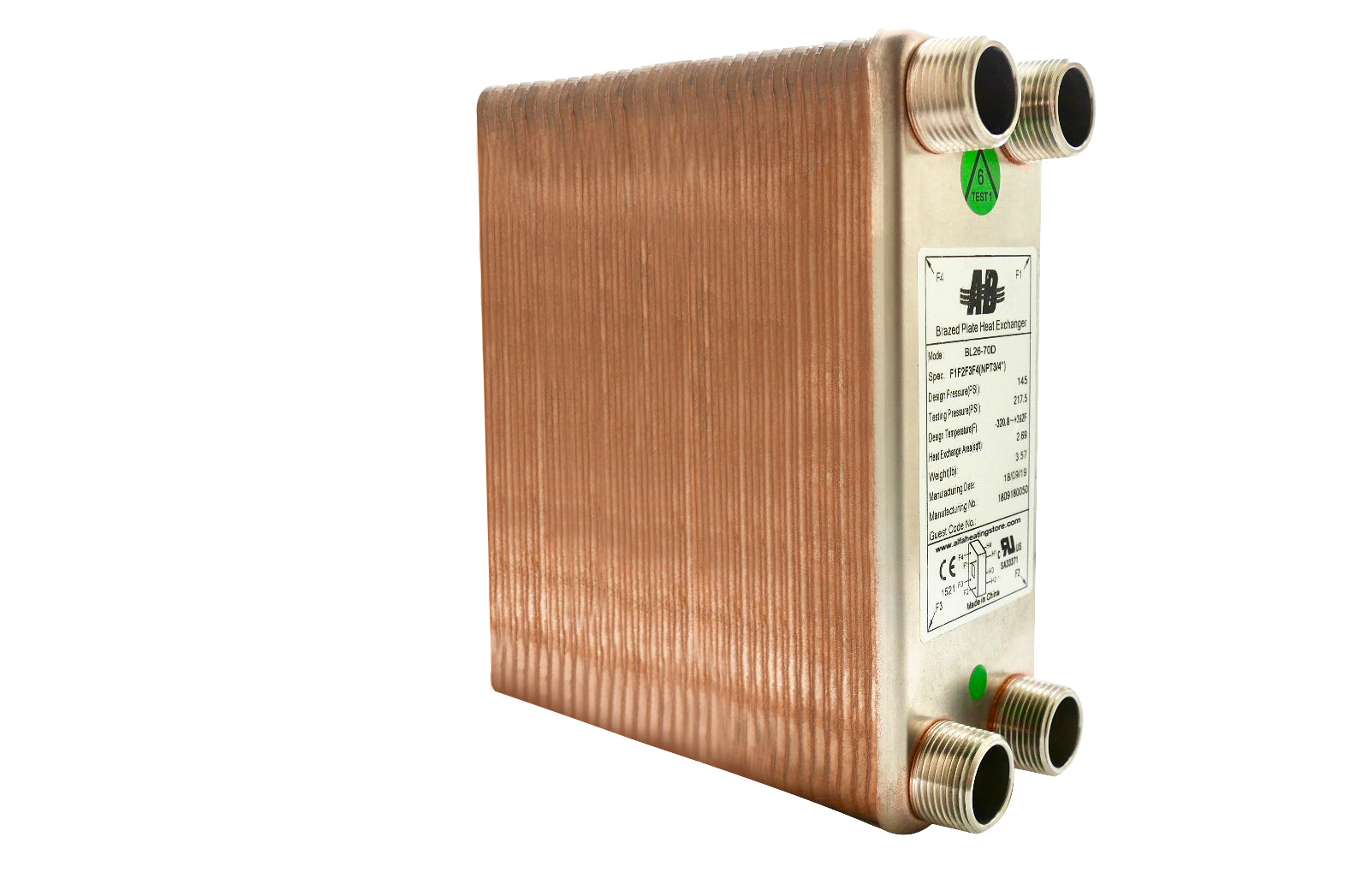

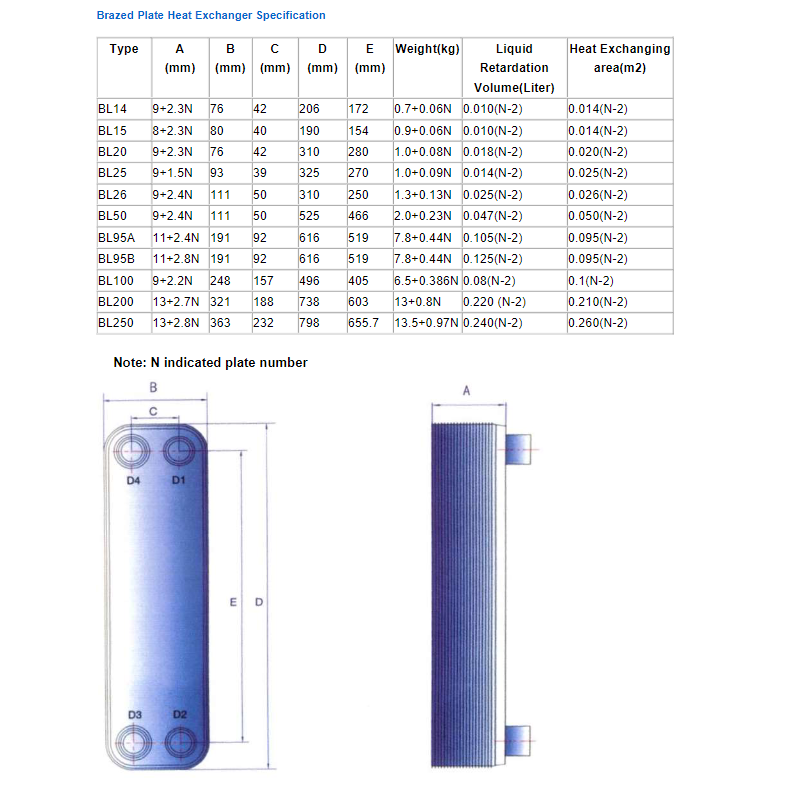

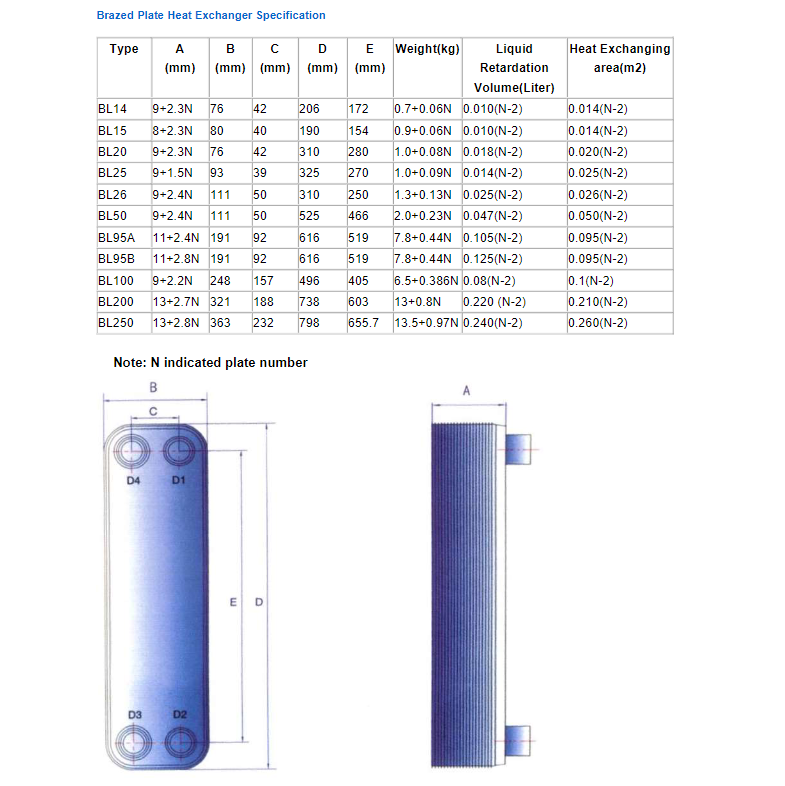

Brazed plate heat exchangers are another strong option. Compact and efficient, these units are ideal for systems requiring high performance in a small footprint. Alfa Heating's brazed plate designs are available in various sizes and configurations, giving engineers and operators the flexibility to fine-tune system capacity. The use of 316L stainless steel ensures corrosion resistance and compliance with food safety standards.

You don’t need to compromise on flow efficiency to maintain cleanliness. The right exchanger should support both. Key features to look for include:

- Sanitary tri-clamp fittings to simplify disassembly and inspection

- High BTU ratings to meet production throughput demands

Ultimately, the best unit is the one that meets your system requirements without introducing operational risk. Alfa Heating provides that balance by combining durable construction with application-specific designs.

In tightly regulated industries like dairy, food processing, and pharmaceuticals, sanitary heating and cooling systems do more than control temperature—they preserve the integrity of the final product and maintain system hygiene at every stage.

In food and dairy facilities, precise temperature regulation is used to pasteurize, chill, or maintain ingredients at safe storage levels. Without this control, spoilage or bacterial growth becomes a serious risk. Sanitary heat exchangers play a central role in this process, rapidly heating or cooling liquids while keeping product contact surfaces clean and sterile.

Pharmaceutical manufacturing demands an even higher level of environmental control. Climate-sensitive compounds must be stored and processed at exact temperatures. Any deviation could reduce effectiveness or cause contamination. Sanitary cooling systems maintain stable ambient conditions, while heating units support mixing, distillation, and sterilization workflows.

Each of these industries requires equipment that avoids cross-contamination. That means systems made from materials such as 316L stainless steel, configured for rapid drainage and full access during cleaning. It also means using components that can integrate into existing CIP procedures, allowing daily operations to continue without extended downtime.

What ties all these industries together is the need for precision, compliance, and reliability. Sanitary heating and cooling solutions help facilities meet strict hygiene regulations while also supporting efficient, cost-effective production workflows.