Looking for a reliable solution to manage heating or cooling in your system? We offer quality heat exchangers and radiators for different setups. Choose from many types, sizes, and connection options to match your needs. Easy to install and built to last. Check out our full selection and get the right model for your project today.

Get More Efficiency from Every Heating System

Looking to improve energy use and heating performance in your home or facility? The right heat exchanger can make that difference. Our products are designed for various applications—home heating, hot water distribution, pool heating, and more—while keeping systems compact, efficient, and cost-effective. With models designed to handle various output levels and fluid types, we offer powerful and adaptable solutions.

Our lineup is engineered to suit both residential and commercial needs. These units ensure reliable thermal transfer, helping systems run smoother and more efficiently. You’ll find models built with different materials, such as stainless steel, copper, and titanium, to match your setup and durability requirements.

Higher performance = lower energy bills and fewer system breakdowns. Explore our range to find solutions built to deliver both now and in the long run.

Built to Support Domestic and Commercial Use

We offer systems easily integrated into everything from small home heating setups to larger industrial applications. Many models in our selection provide flexible port options and come in different configurations, like side-arm and shell-and-tube, to suit installation needs.

If you’re heating a floor system, managing a domestic hot water setup, or maintaining optimal temperatures for pools and spas, our designs can meet those challenges. Their compact construction makes them ideal even for tight mechanical rooms. Our thermal exchanger options are built to operate under pressure, handle high-temperature differentials, and offer consistent thermal transfer with minimal maintenance.

Smart engineering = fewer surprises and lower upkeep. Choose a unit that adapts to your demands, not vice versa.

Understand the Benefits of Plate Technology

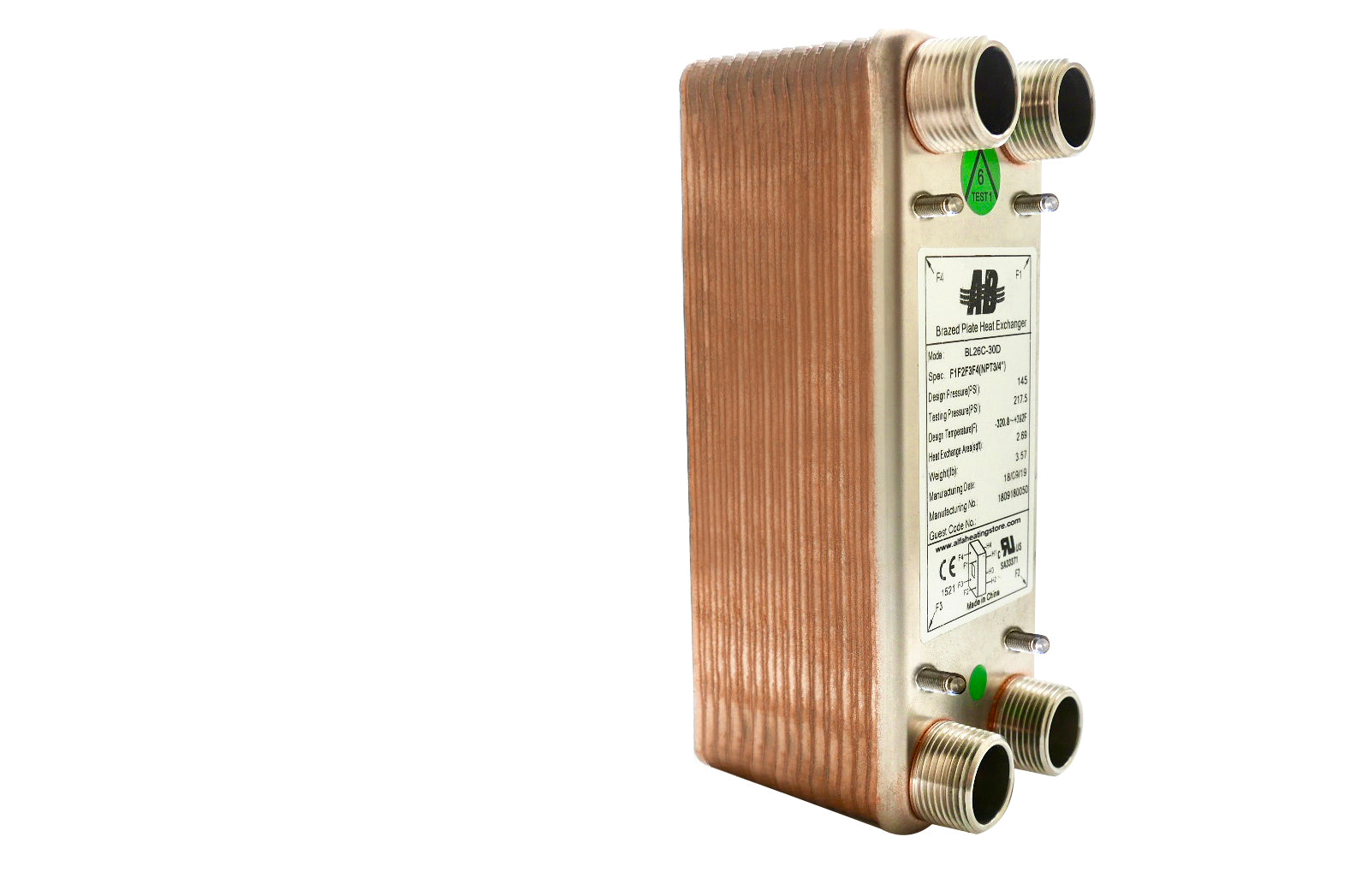

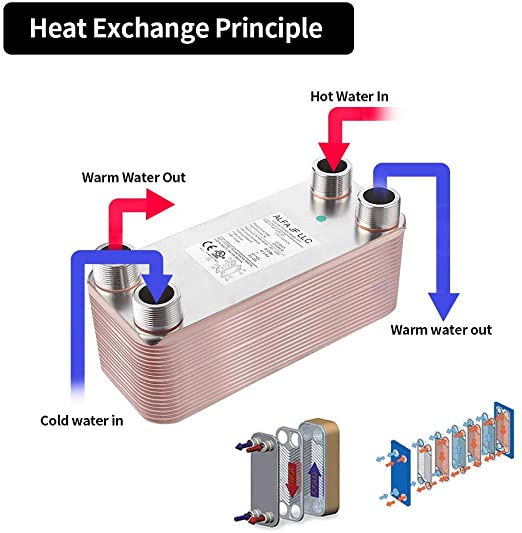

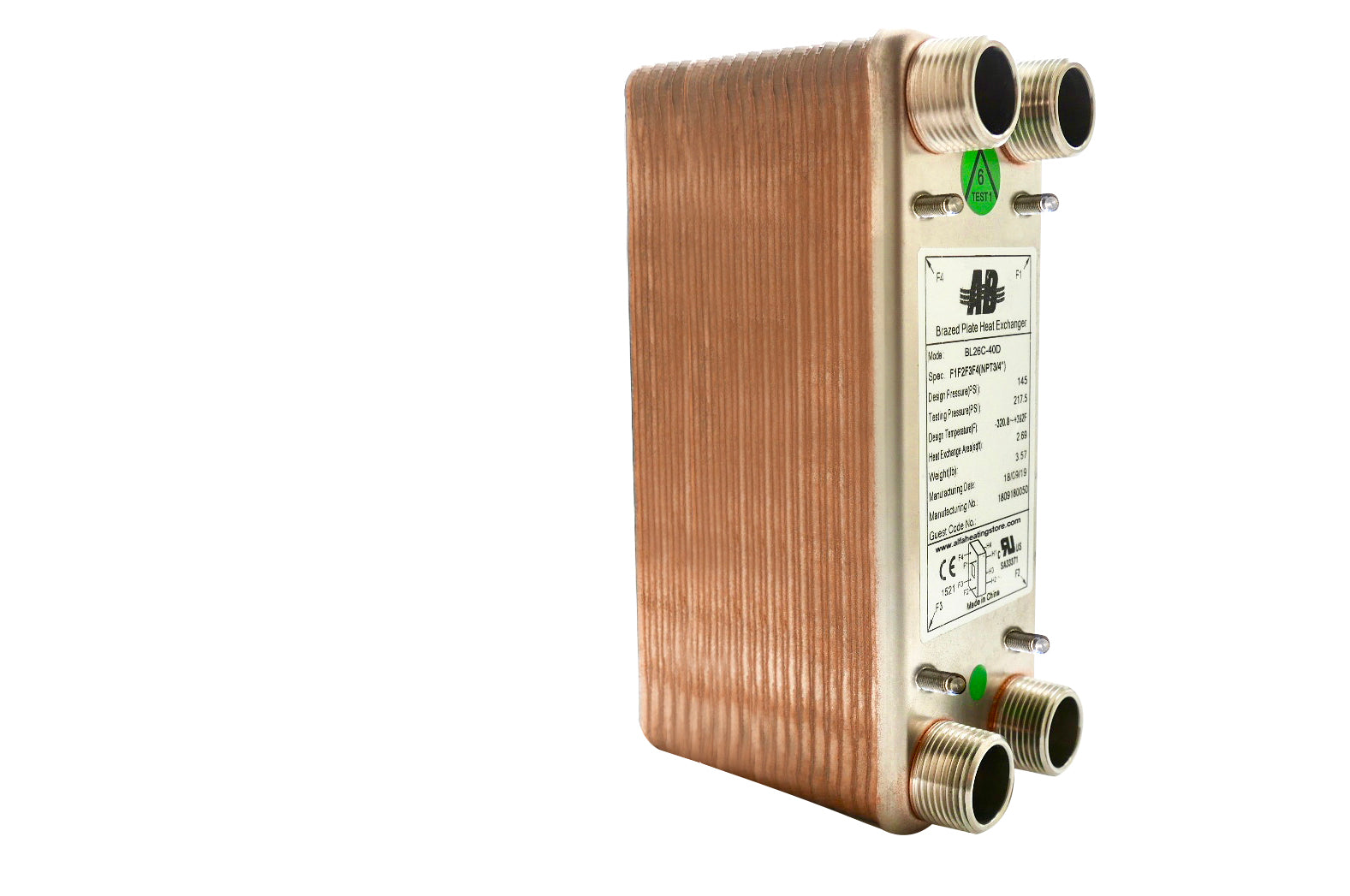

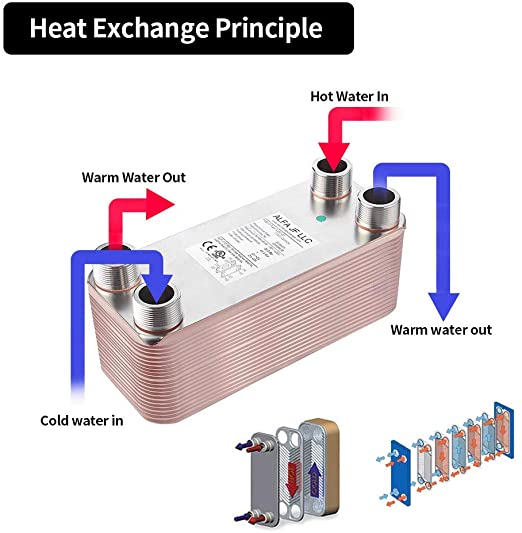

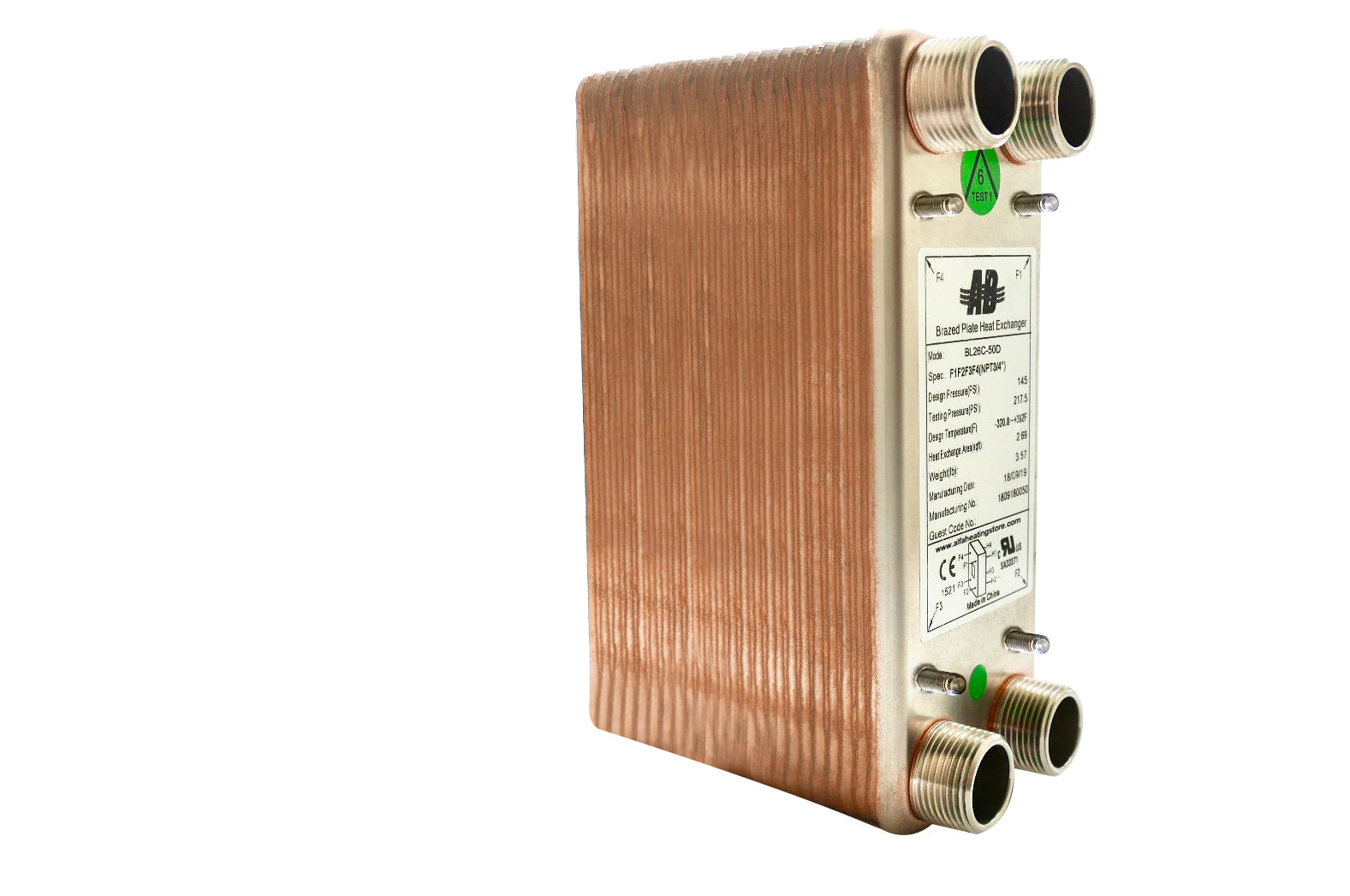

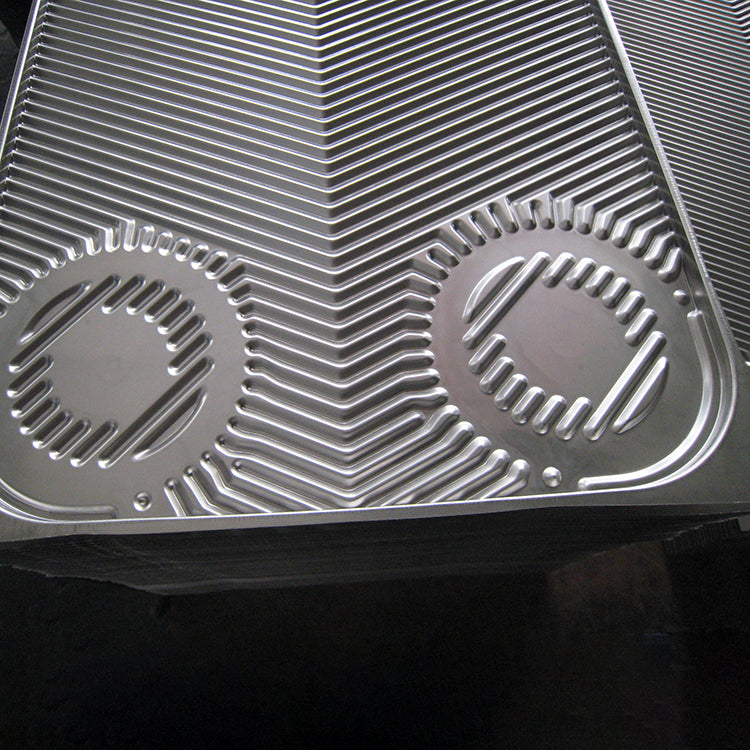

One of the standout solutions in our collection is the plate exchanger. These units use stacked metal plates instead of traditional pipe coils, significantly increasing surface area and heat transfer efficiency. They are ideal for use where space is limited, but thermal performance can’t be compromised.

Our plate models are often used in floor heating, domestic water, and cooling loops. Thanks to their efficient design, they can handle quick temperature shifts and maintain consistent flow without added bulk. Stainless steel construction also helps resist corrosion over time, especially in closed-loop systems.

More compact surface area = better efficiency in tighter spaces. These units deliver the performance you need without wasting valuable room.

Designed to Work with a Wide Range of Fluids

System compatibility matters. Our fluid heat exchanger options are engineered to work with water, glycol mixes, and other heating fluids, depending on the system setup. You can integrate them into closed or open systems without worrying about material degradation or transfer loss.

Applications include pool water, hydronic heating, solar systems, and snow melt setups. Choosing the right model is crucial to avoid performance bottlenecks and achieve steady, reliable thermal flow. All units are tested for pressure resistance and thermal performance, so you can count on consistent output from day one.

Better compatibility = more freedom in system design. Invest in equipment that works well with the fluids you’re already using.

Exploring the Impact of Industrial-Grade Solutions

We also supply products suitable for commercial buildings, manufacturing plants, and institutional heating systems. Each industrial heat exchanger we offer is built for high-capacity thermal transfer. These units are optimized for durability, large-volume flow, and ease of cleaning or replacement in high-demand setups.

They support HVAC integration, heat recovery systems, and even high-performance solar installations. Models rated for exceptionally high BTU outputs are available in various materials based on the application’s corrosiveness and pressure levels. Industrial quality ensures longer lifespans, less downtime, and better long-term savings.

Durability + performance = lower operational costs. These are built to meet the demands of challenging environments without compromise.

Choosing the Right Model

If you’re unsure which system suits your needs, identify your heating fluid, system capacity, and application type. We provide a wide range of sizes, connection types, and layouts so you can choose the best match without overpaying for excess capacity. Everything in our range is crafted for performance and longevity, from compact home units to heavy-duty commercial builds.

Each heat exchanger is made with precision and tested for performance. Every thermal exchanger in our lineup is selected to meet exacting quality standards. We aim to simplify your selection process by offering clear product specs and reliable customer support.

Have a setup in mind? Explore our selection and choose the right plate exchanger, fluid heat exchanger, or industrial heat exchanger for your next project.

FAQ

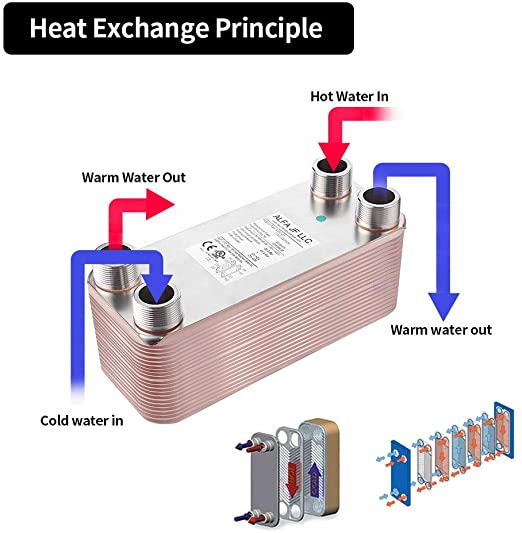

A heat exchanger is a device that transfers heat from one fluid to another without mixing them. It’s commonly used in systems where heating or cooling needs to happen efficiently across separate loops. For example, it might move heat from a hot water system into a pool or shift thermal energy from one part of a building to another.

The process relies on the principle of thermal conductivity. Fluids—such as water or glycol—flow through metal surfaces, typically made of copper, stainless steel, or titanium, which quickly transfer heat. The two fluid circuits stay isolated but exchange temperature through this barrier. This setup makes heat exchangers reliable and low-maintenance because the fluids don’t contaminate each other.

Many models are compact enough to fit in tight mechanical rooms or behind wall panels, and are designed to handle high pressures and temperature differences. Systems stay efficient without needing oversized equipment.

Some of the most practical uses include:

- Floor heating systems

- Domestic hot water setups

- Pool and spa heating

- Industrial process temperature control

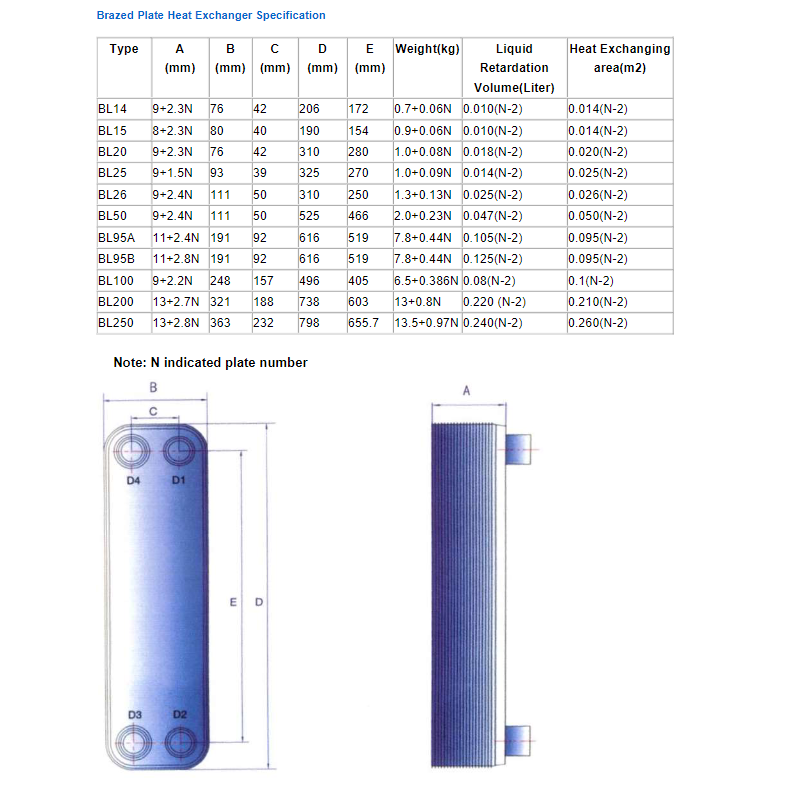

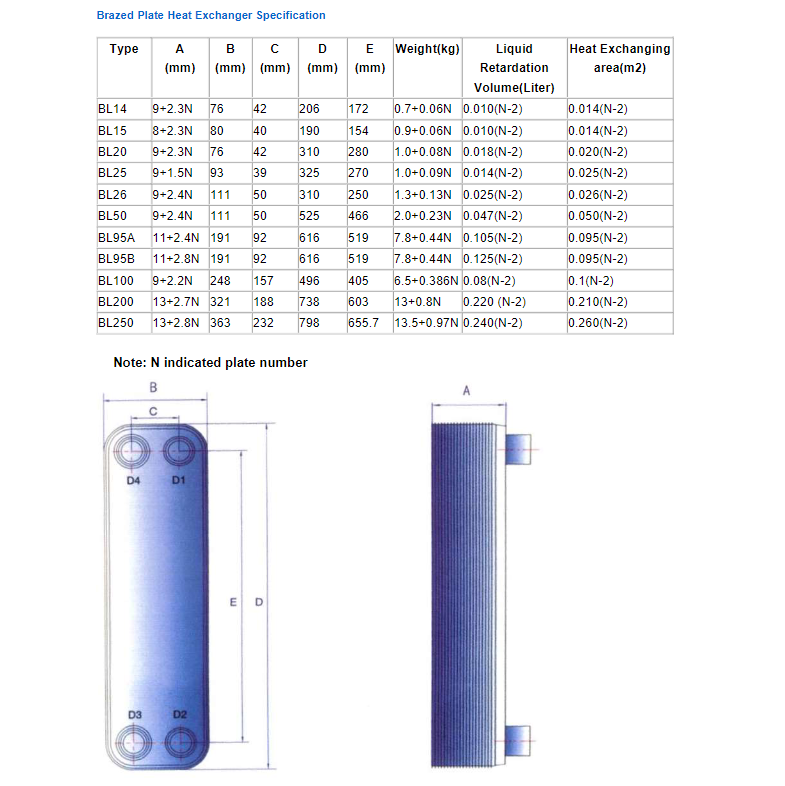

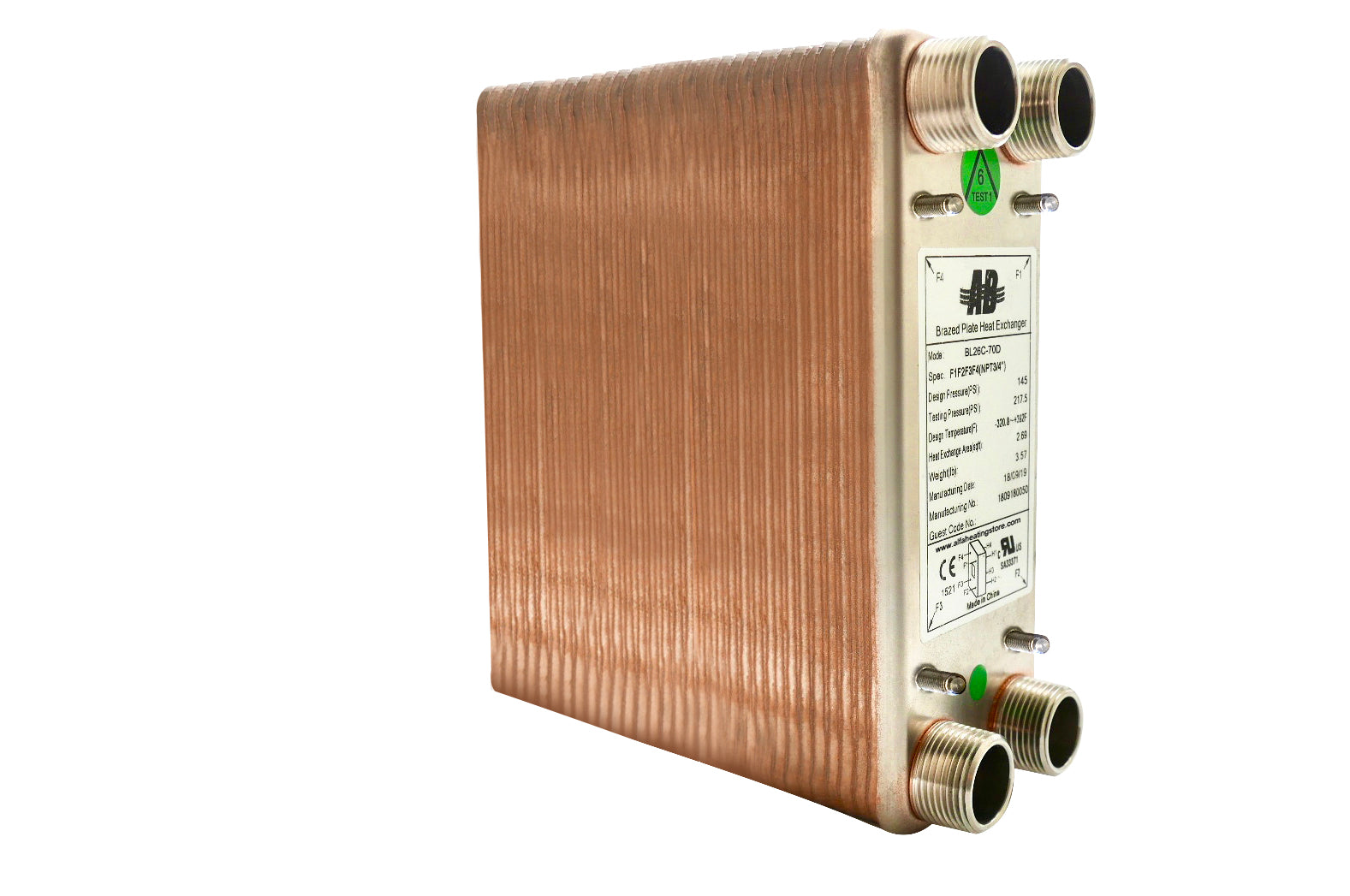

Heat exchangers come in a range of formats, each tailored to different needs. One of the most widely used designs is the brazed plate heat exchanger. It stacks multiple metal plates to create large surface areas within a compact frame, which improves heat transfer while minimizing space requirements. These are ideal for applications like water heating or hydronic systems.

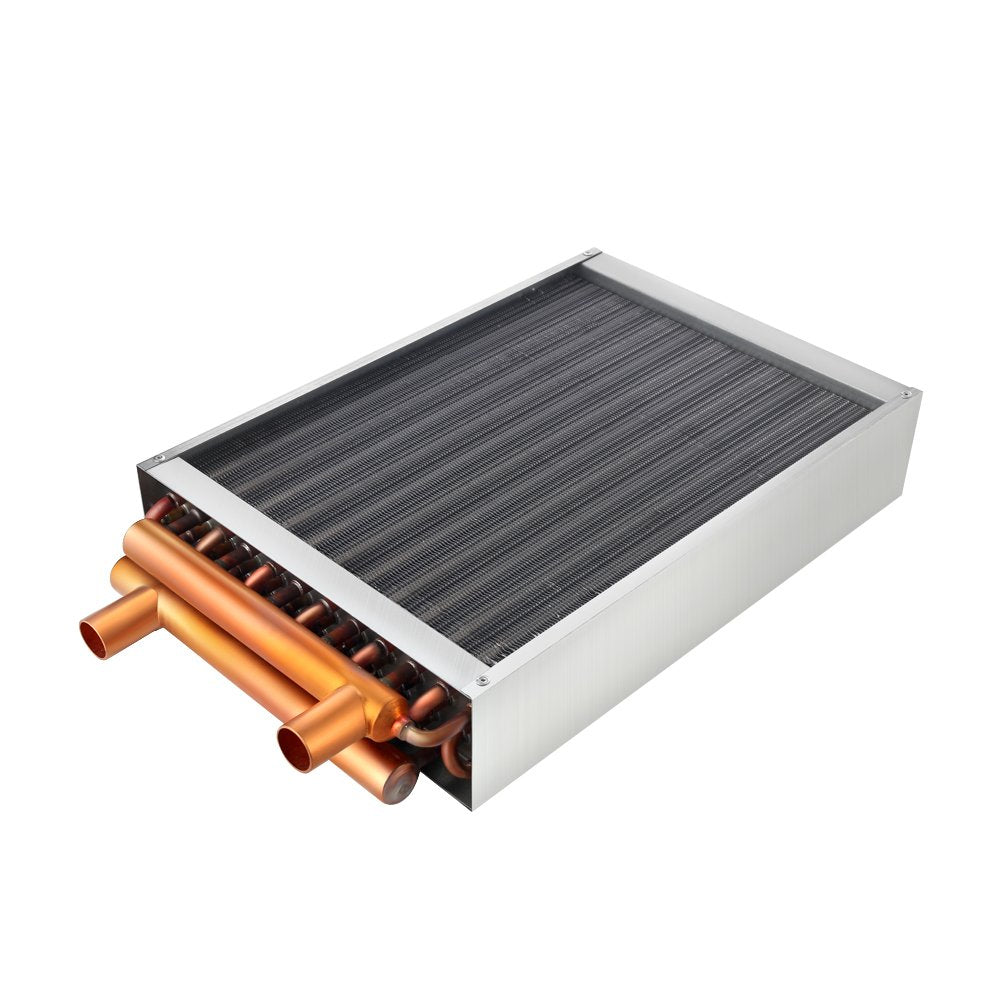

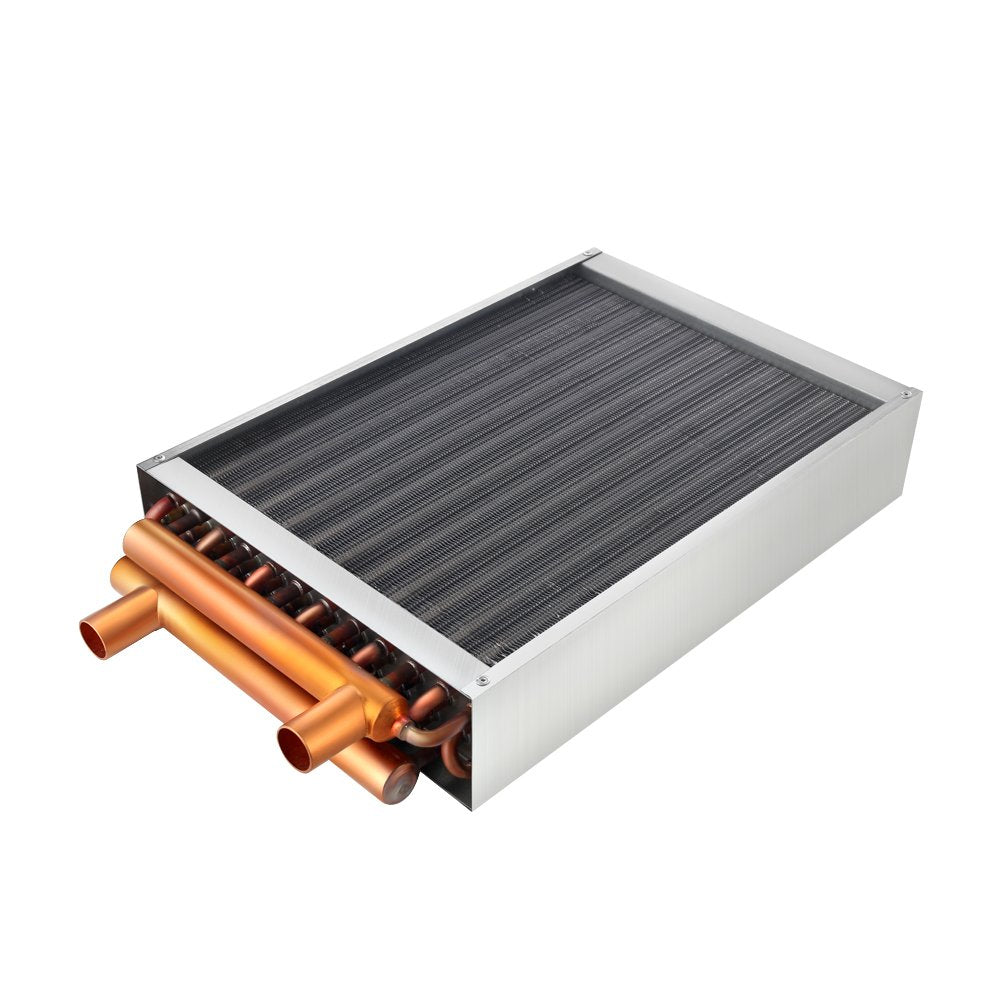

Air-to-water heat exchangers are another popular option. These use a fan or blower to move air across finned tubes carrying hot or cold fluid. They’re commonly used in HVAC and ventilation systems to regulate room temperatures efficiently.

Side-arm models work well for domestic water heating. They attach to your existing water heater and utilize either passive convection or pumped flow to transfer heat between the tank and external systems.

For swimming pools or corrosive environments, titanium or 316L stainless steel versions are preferred. These materials handle saltwater or chemical-treated systems without degrading over time.

Some setups require shell-and-tube or double-wall designs, especially in industrial or code-regulated environments. These add safety layers or allow for easier maintenance.

Start by identifying three main factors: your fluid type, heating or cooling capacity, and how the unit will be connected to your system. Once those are clear, it’s easier to narrow down the right heat exchanger.

Let’s break it down:

- Fluid type: Some heat exchangers work best with water, while others work with glycol or corrosive mixes, such as saltwater. For pools or spas, stainless steel or titanium is the ideal choice. For closed-loop systems, copper can be more than enough.

- Capacity: Look at the BTU rating to match your system’s needs. Undersized units won’t deliver enough heat transfer. Oversized ones take up space and increase costs without adding benefit.

- Connection ports and layout: Installation space matters. Some models come with same-side ports, others with opposite-side ports. Choosing the right layout saves time and hassle during setup.

Systems vary—so should your choice. A unit built for residential hot water won’t work well in a commercial boiler loop. A plate exchanger intended for floor heating may not withstand exposure to pool chemicals.

Material compatibility leads to a longer lifespan and improved performance. Investing in a heat exchanger that fits your exact setup keeps energy bills low and maintenance to a minimum.