Plate & Heat Exchangers are the most common type of heat exchangers found in the industry today. Their popularity is one of the main reasons why these pieces are seen everywhere on the internet and there are so many tutorials on how you can repair and maintain these items. Well, ours is just another informative article for you to get acquainted with these know all about them. Whether you're an experienced engineer or just another enthusiastic do-it-yourselfer, we have presented all the information for you to learn everything about these brazed plate heat exchangers.

What are Plate Heat Exchangers and their Types?

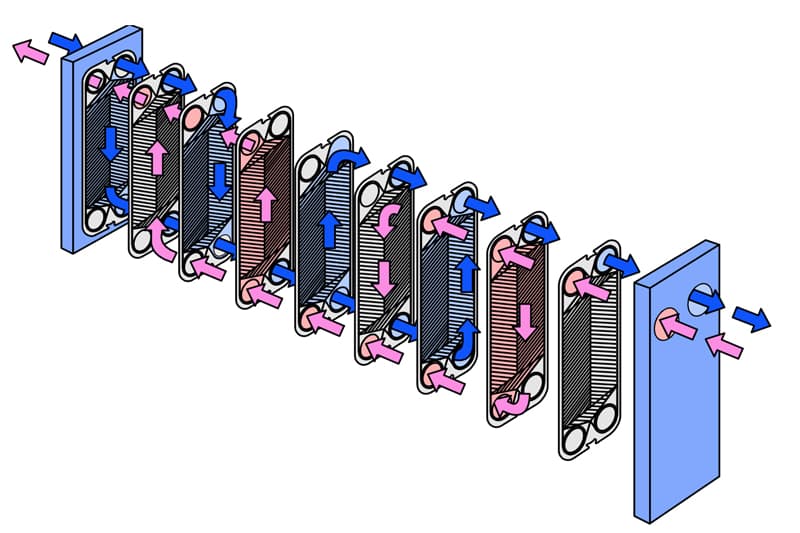

A plate heat exchanger, also known as a plate and frame heat exchanger, is a piece of equipment that functions to transfer heat from one liquid to another. It has several plates on one side of the device and an open space on the other side. The liquid flows through the open space while the plates are immersed in it. From making beer to heating up water, they can be used for just everything.

There are two basic types of plate heat exchangers:

- Vertical

- Horizontal

Vertical units are used where space is at a premium or where a process fluid must be exposed to air. Horizontal units, on the other hand, are typically more popular due to their efficiency and ease of installation.

How do Plate Heat Exchangers work?

If you're curious about how these plate heat exchangers work, there's no need to think about the same anymore. By gathering several facts from the internet and much by observing its working, we have gathered a piece of great information for you which will help clear all your doubts.

Their working is quite easy as they work by simply transfer of heat between fluids by means of a physical process. These fluids are forced past each other, and the plate is used as a surface for this contact. Because these are made by the use of metal, it becomes easy for fluids to pass through them.

In the former types of these devices, hot water was used which easily entered the bottom side of the exchanger and flowed upwards through it. But in the latest versions, cold water simply enters the top side and flows downwards. The two streams then collide in the center of the exchanger, where they exchange heat until both are at approximately equal temperatures.

What are some Industries that use them?

Plate heat exchangers are one of the most common types of heat exchangers in use today. From food and beverage production to chemical processing, and power generation, they're used in a variety of industries.

Conclusion

Plate heat exchangers are one of the most common types of heat exchangers used in industrial applications because they have high thermal efficiency and are effective at handling a wide range of temperatures. So, if you haven't experienced using them, it's high time you should do it. With great quality, they have you an experience of a lifetime.