Plate heat exchangers were originally manufactured in the 1920s and are now widely employed in a variety of industries.

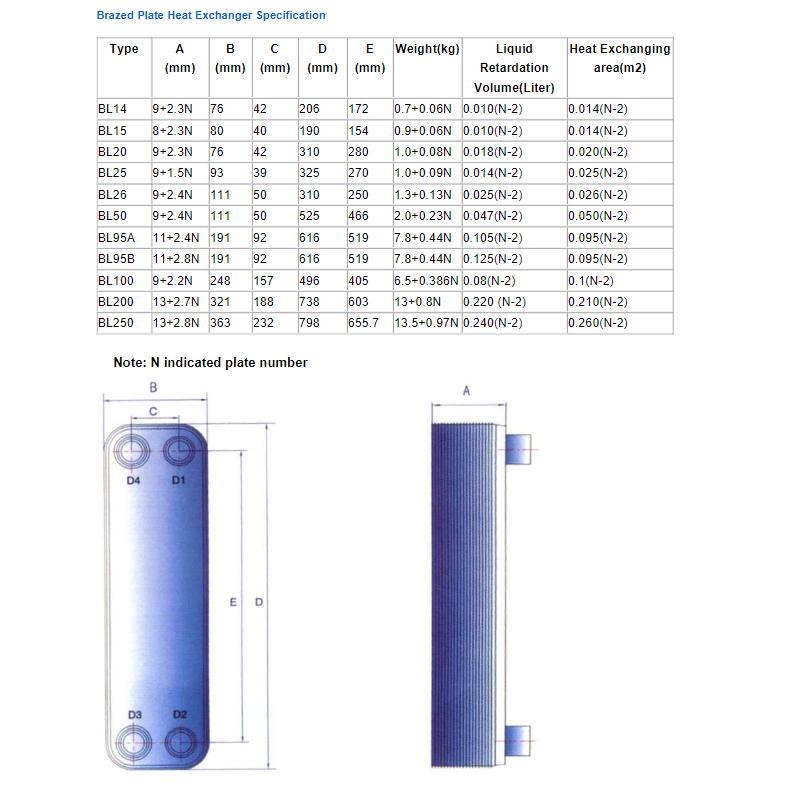

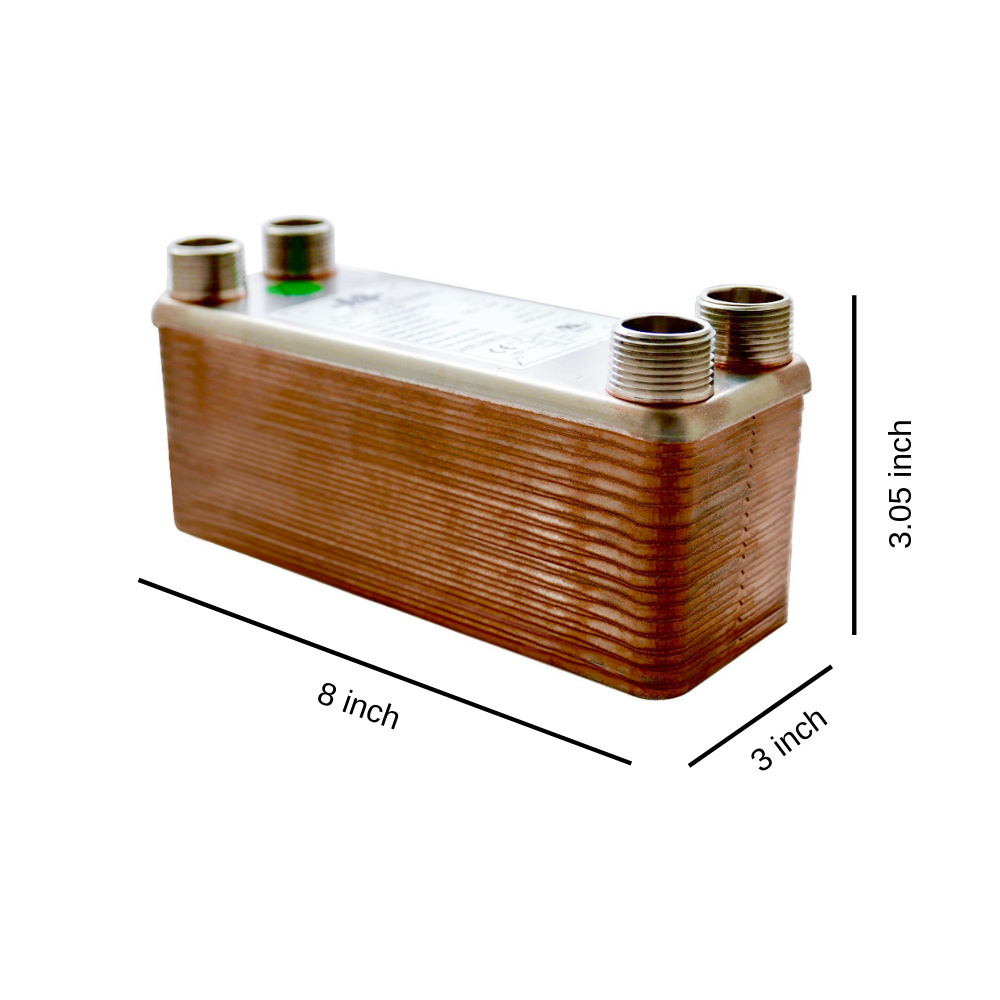

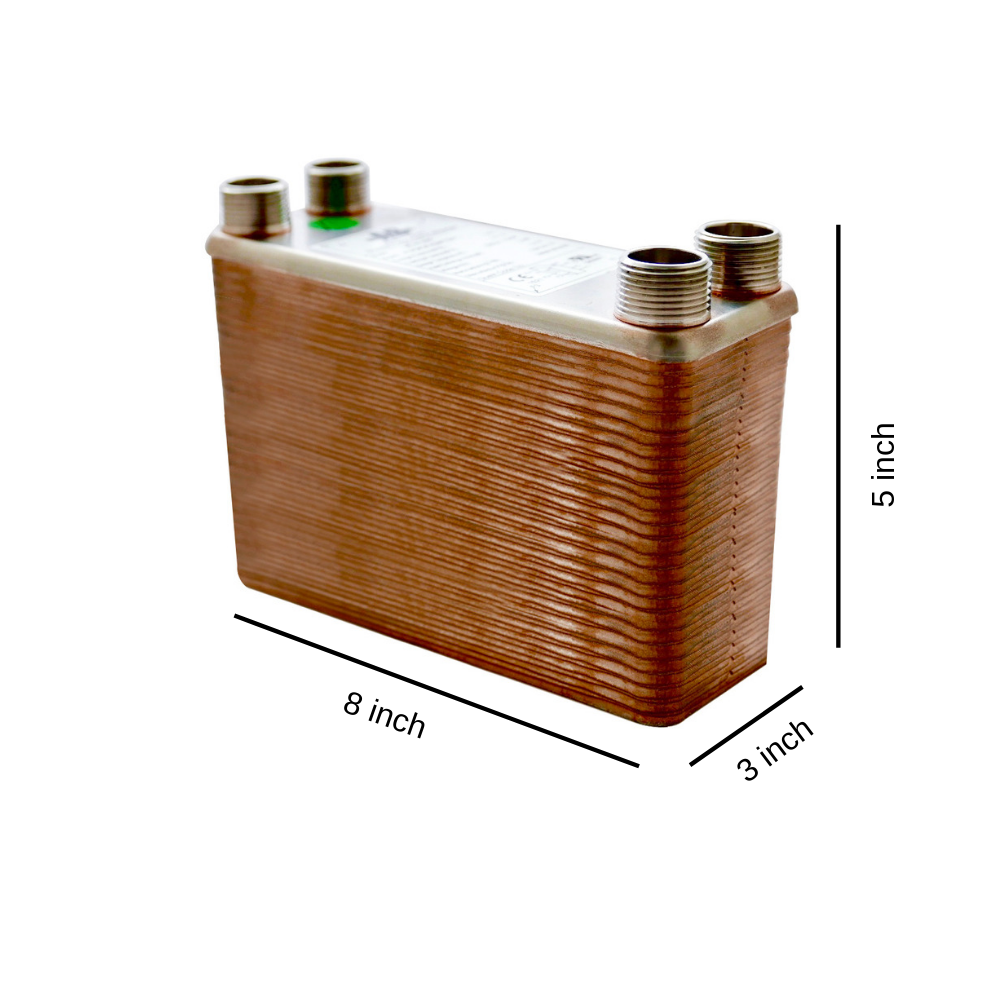

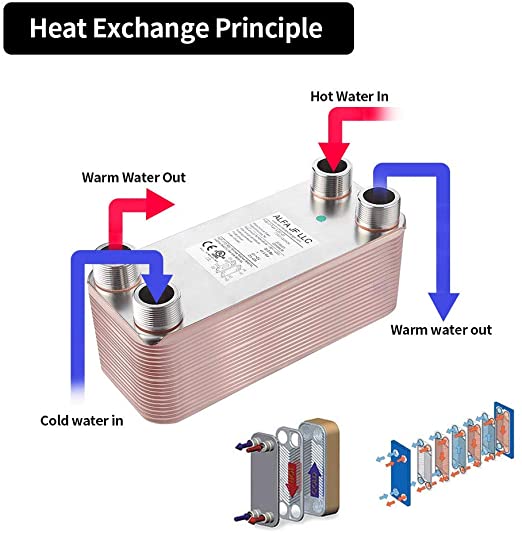

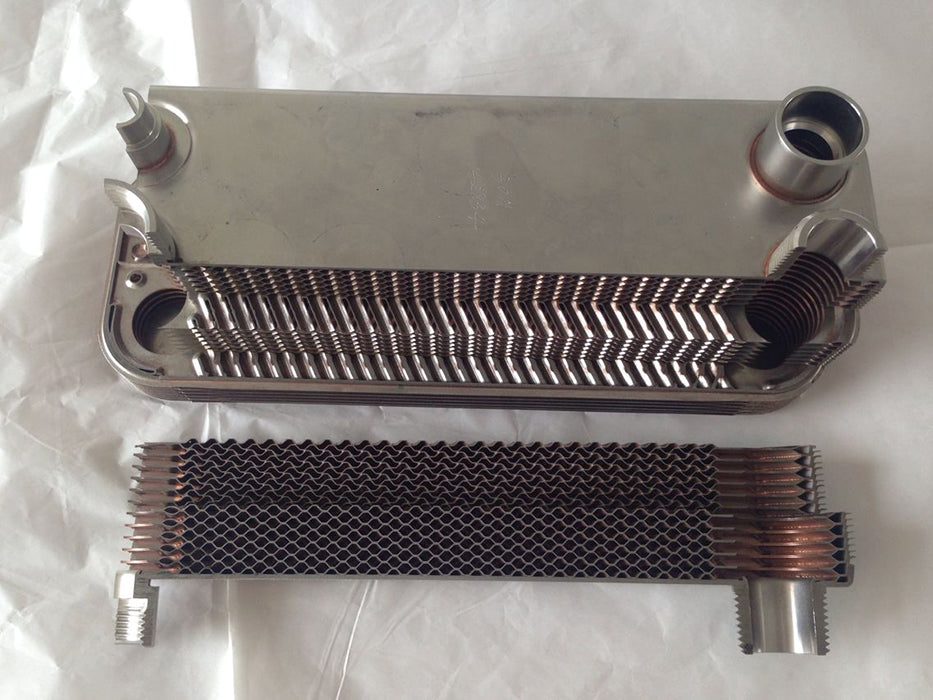

A plate exchanger is made up of several parallel plates that are stacked one on top of the other to generate a series of channels through which fluids can flow.

The channel in which the fluid flows is formed by the gap between two adjacent plates. The whole system and working of a plate heat exchanger are quite complex.

What is a Plate Heat Exchanger?

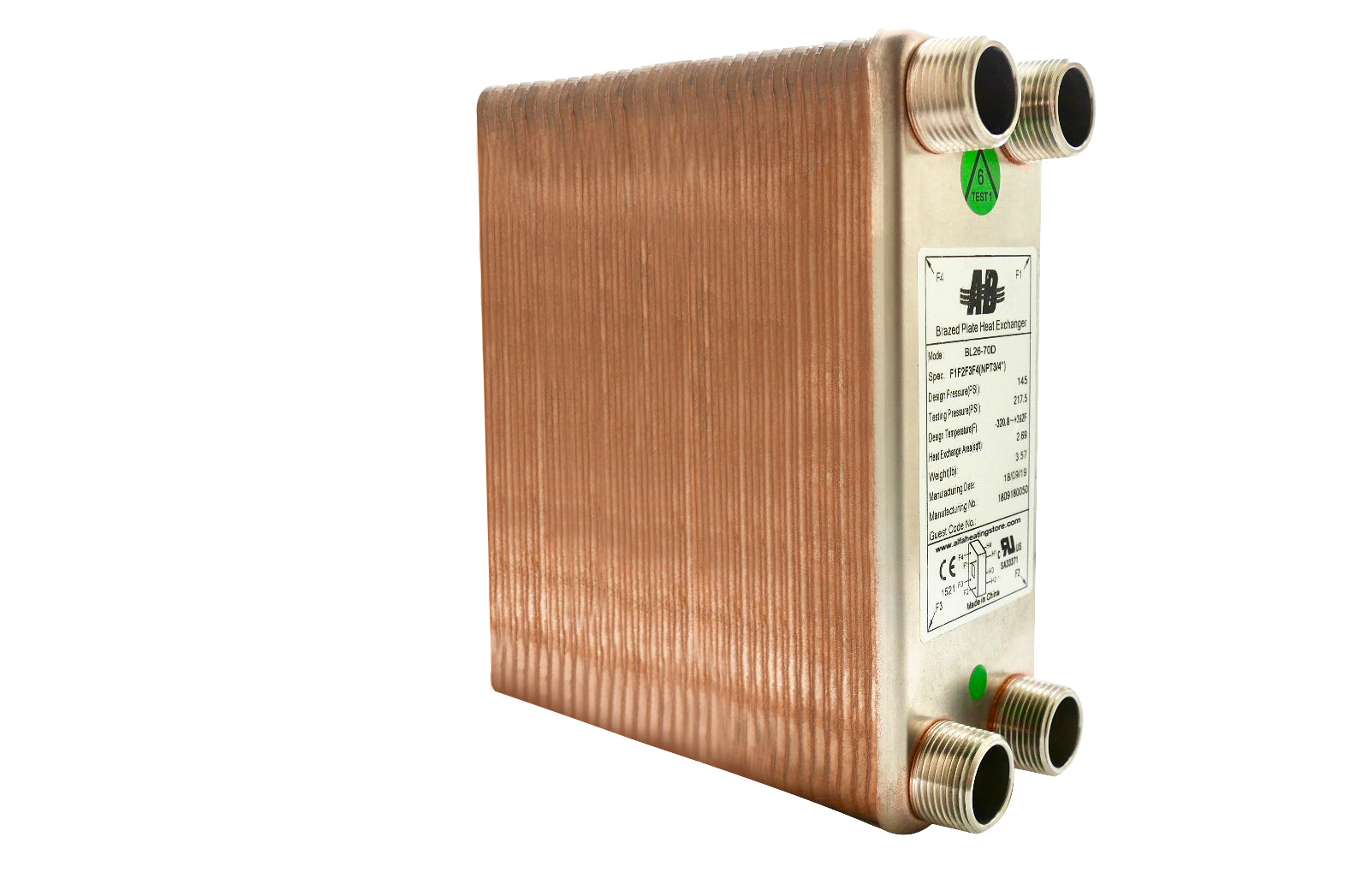

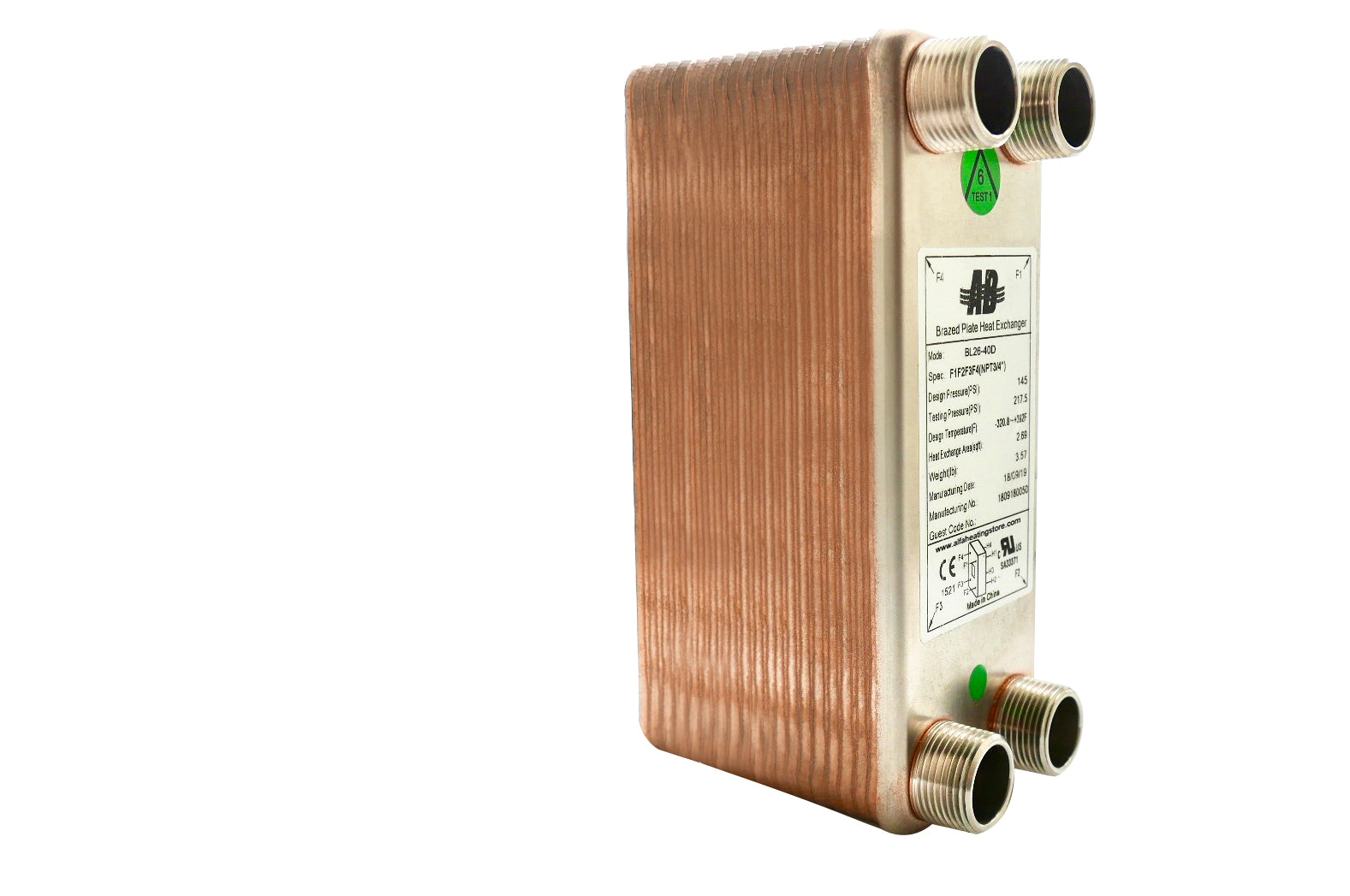

A plate heat exchanger transfers heat from one fluid to another through a series of metal plates. These plates in this exchanger are stacked on top of each other to form a series of channels through which fluid can flow. The plate heat exchanger was introduced by Richard Seligman in the 1920s.

The fundamental advantage of plate heat exchangers over traditional heat exchangers is that the fluid is dispersed across the plate, exposing the fluid to a wider surface area. This accelerates the rate of temperature change by increasing the heat transfer rate.

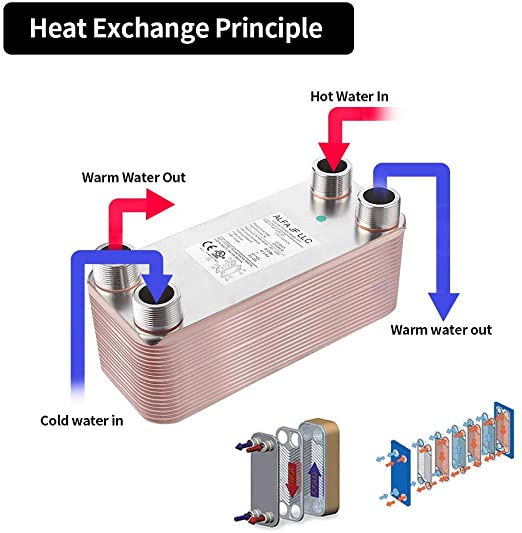

How it Works

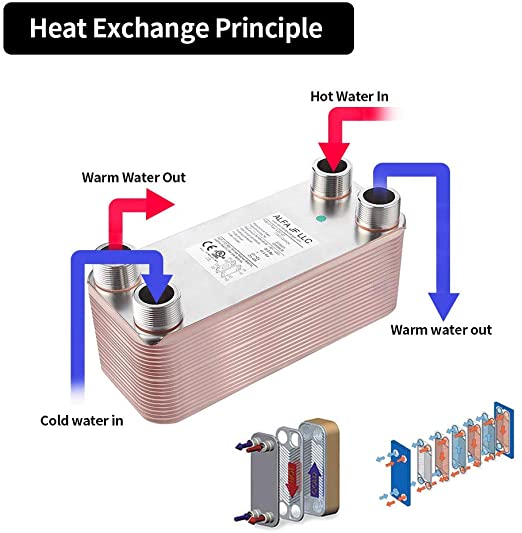

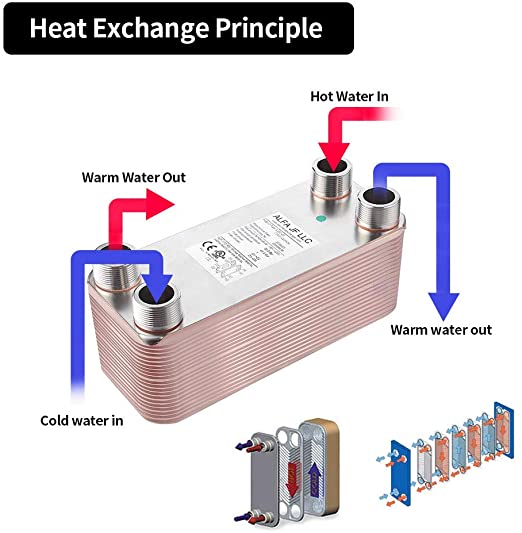

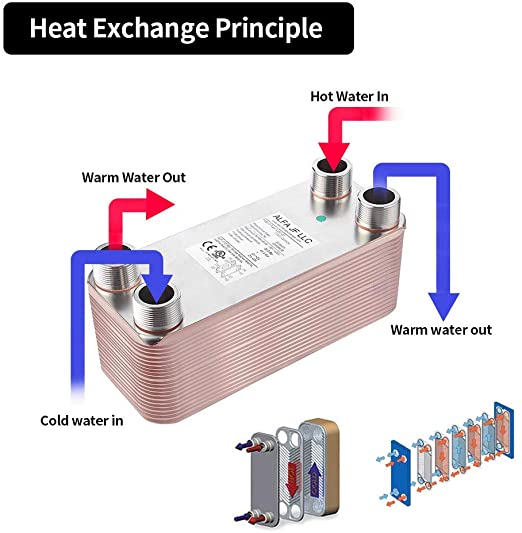

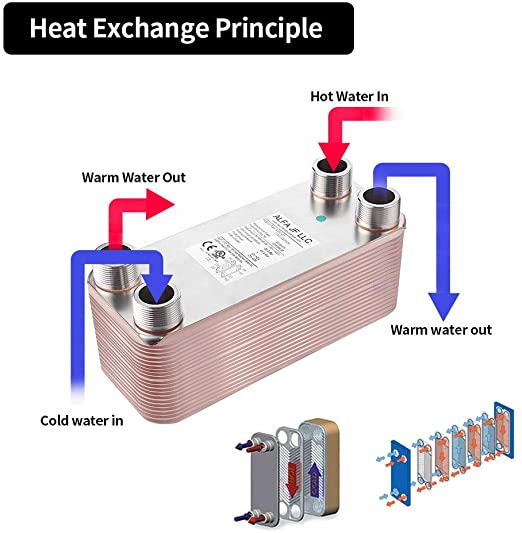

The plate heat exchanger operates on the thermodynamic concept. Each plate in these exchangers has a restricted, hollow tubular casing.

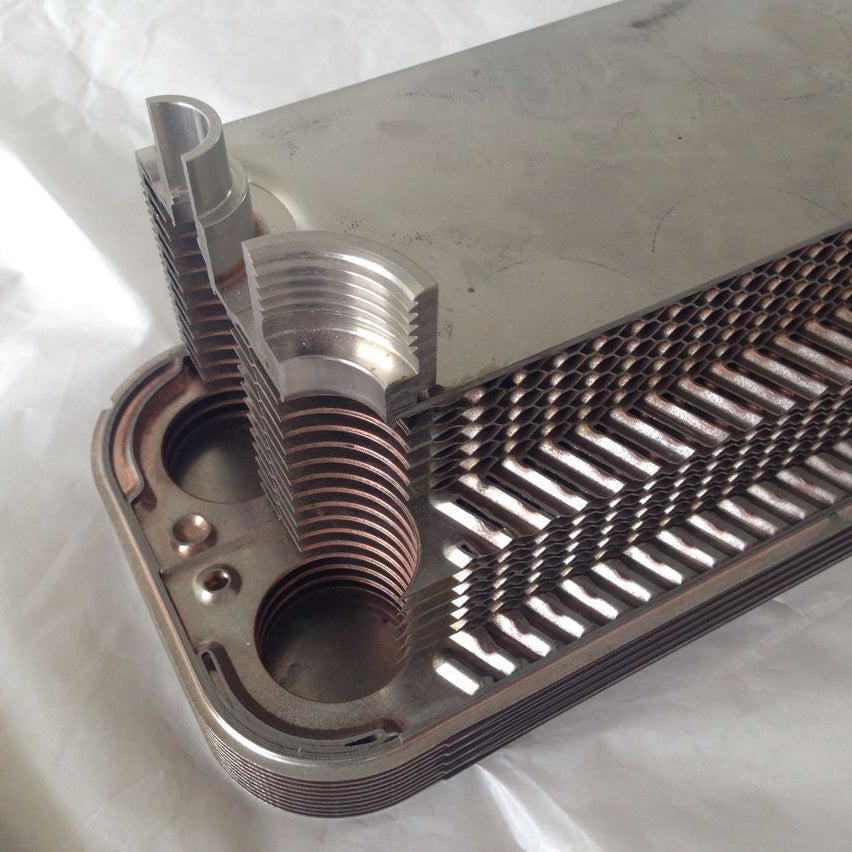

The plates are positioned in such a way that tiny rectangular channels are formed, allowing heat to be exchanged via half-pieces. Between any of these twisted and restricted channels, the operational fluid flows.

To regulate fluid flow, the plates of this exchanger are encircled by gaskets. These gaskets are arranged such that just one type of liquid, such as water or oil, is distributed on one plate, while another fluid, such as lukewarm water, is distributed on the next plate.

Benefits of Choosing Plate Heat Exchangers from WiseWater Alfa Heating Company

Here are some of the advantages of purchasing plate heat exchangers from WiseWater Alfa Heating Company which make them one of the most viable options when it comes to heat exchangers –

- Efficiency - One of the most significant benefits of plate exchangers is the efficiency that comes with their small size. These types of heat exchangers are made up of multiple perforated plates attached to the equipment's frame, resulting in a design that makes use of the entire body in the heat transfer process. This pure surface design causes a lot of turbulence and wall shear stress, which results in a lot of heat transmission, making them very efficient.

- Flexibility - Another benefit of plate heat exchangers is that they can readily adapt to capacity variations, ensuring that the size and quantity of plates necessary for your application are never an issue. Plate heat exchangers can have additional plates added or removed to improve or reduce transfer capacity.

- Serviceability - Plate heat exchangers are considered easy to clean and maintain since their plates may be removed without totally unplugging the heat exchanger. When your plate exchanger requires maintenance, a professional only needs to remove the plate pack and clean it. If the plate has to be replaced, your device won't be down for long because its plates can always be switched out thanks to its improved design over other types, which allows for easier access.

How to Choose Plate Heat Exchangers:

Plate-and-frame heat exchangers come in a variety of configurations. A gasket plate-and-frame configuration is the most prevalent in the market.

A fully synthetic rubber gasket is inserted between the plates to produce fluid channels in a gasket plate-and-frame system. Due to the operating limits of the sealant, this design may be limited in terms of temperature, pressure, and fluid compatibility. If the design considerations for a process application allow for a gasket plate-and-frame layout, make sure the fluids that pass through the unit are suitable for the seals. The gasket plate-and-frame exchanger assembly has an easy-to-clean design, and the fouled plates are easy to replace.

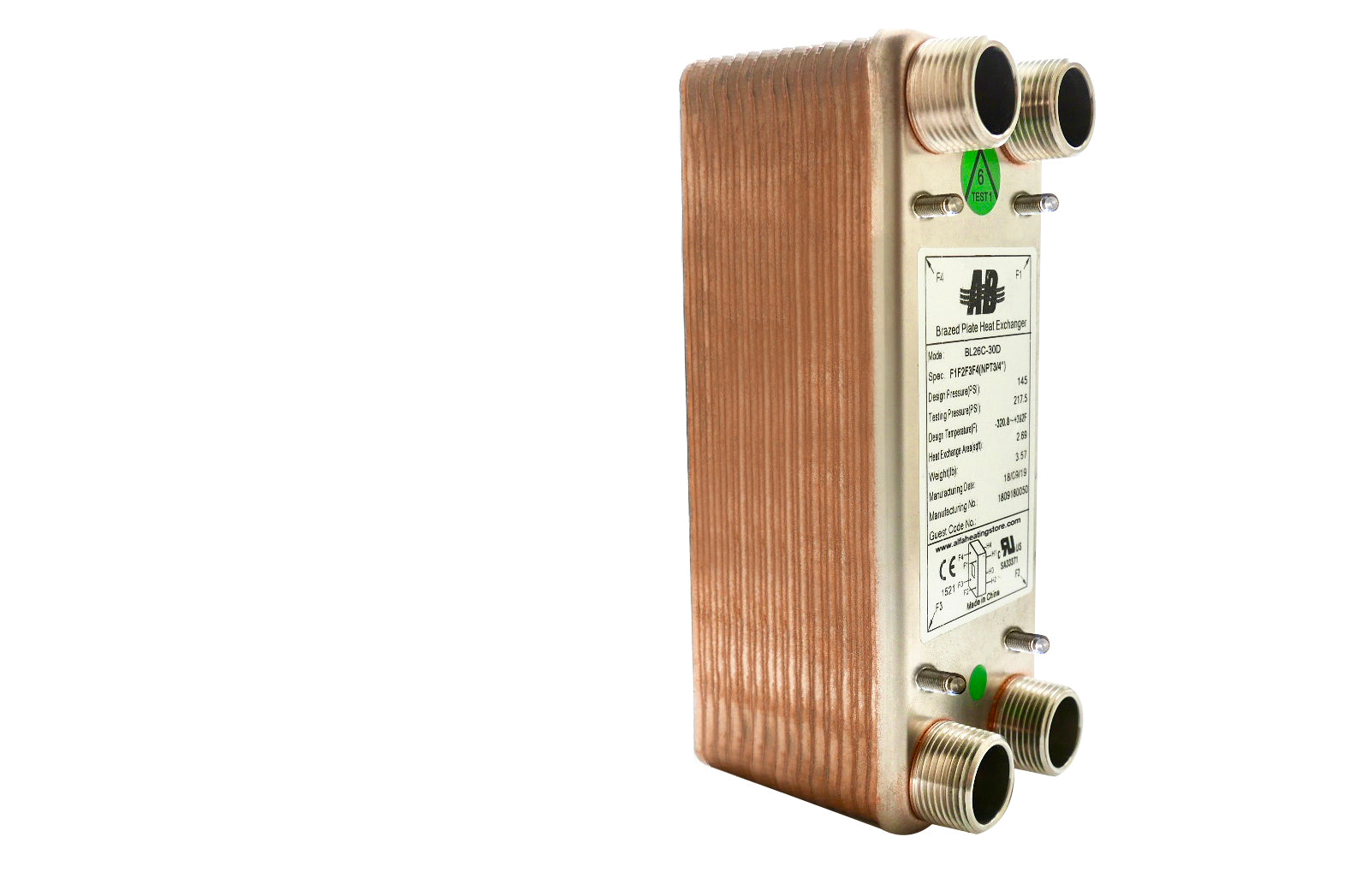

An all-welded unit is a second alternative for a plate heat exchanger. This design does not have the temperature and pressure limits of a gasket design since it is not built with gaskets. Several process applications employ welded plate exchanger layouts.

The all-welded construction provides superior corrosion resistance in addition to increased operational design parameters. All-welded devices need more work to clean than gasket plate types. When properly maintained, they are not prone to fouling and can provide long-term serviceability. There's also no risk of leakage with the all-welded design, which might be a concern with the gasket designs for plate heat exchangers.

Related Heat Exchangers

- Air to Water Heat Exchangers

- Water to Air Heat Exchangers

- Water to Water Heat Exchangers

- Plate Heat Exchangers

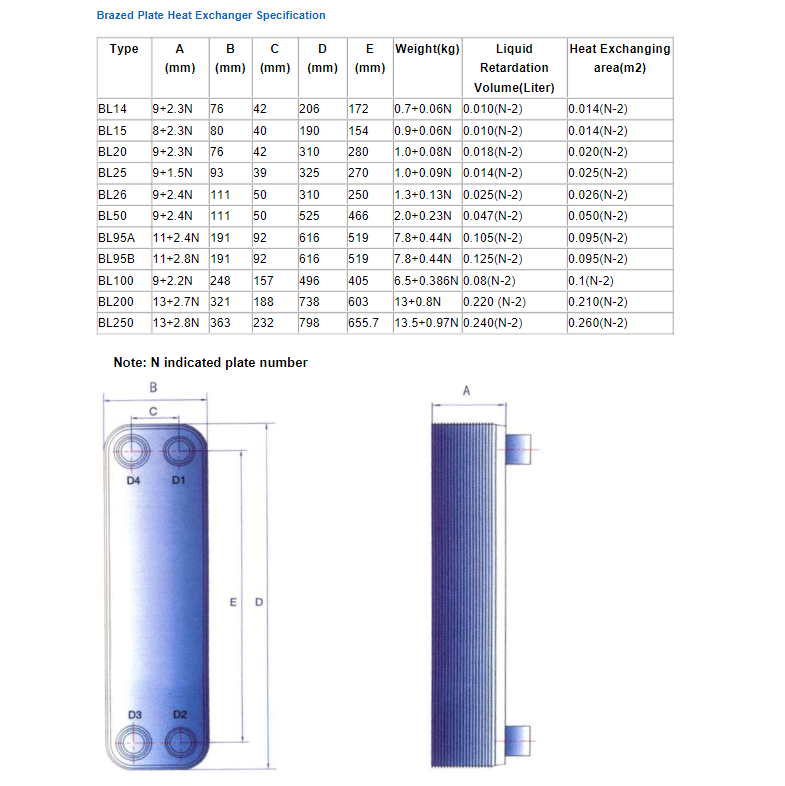

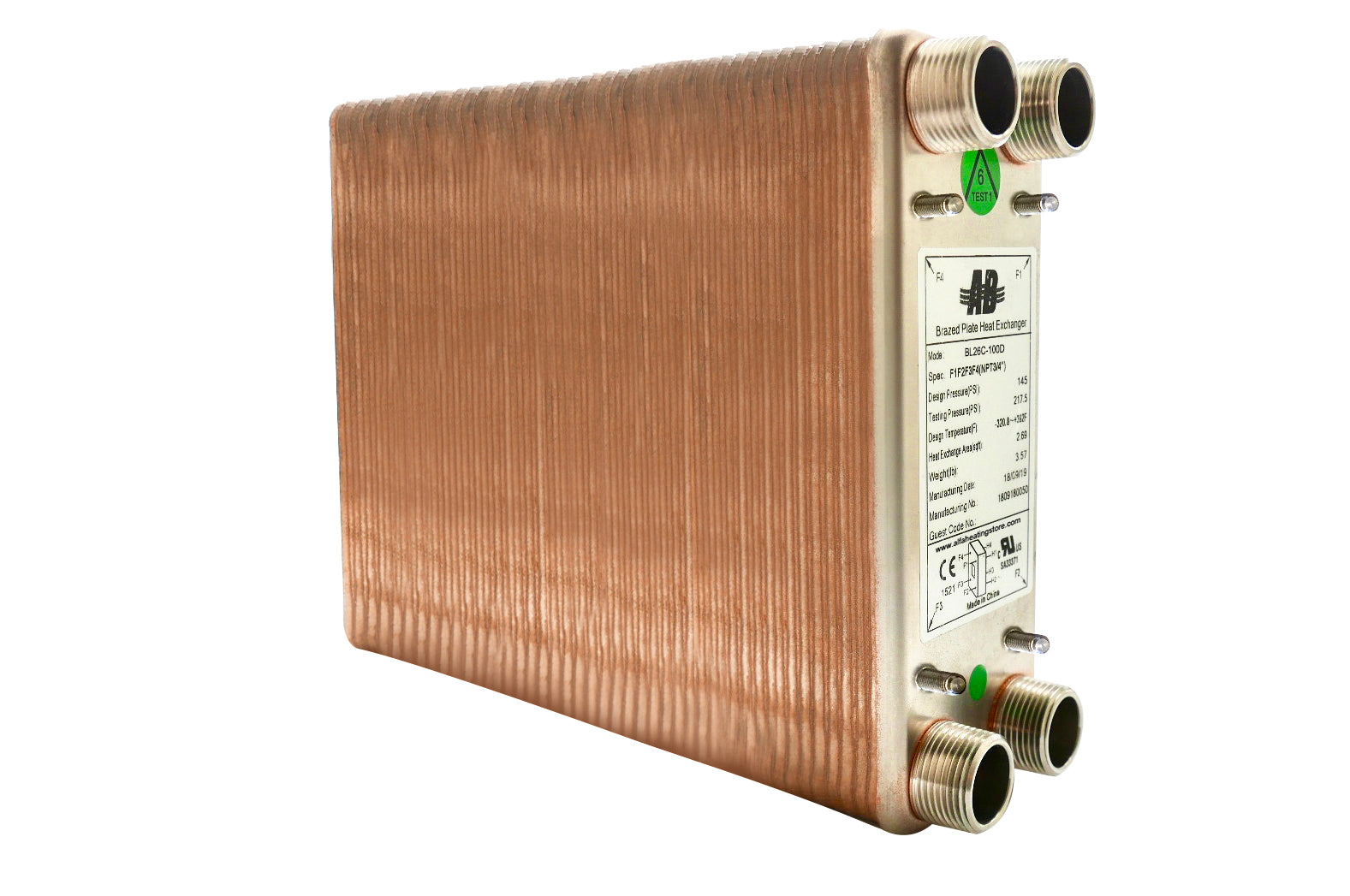

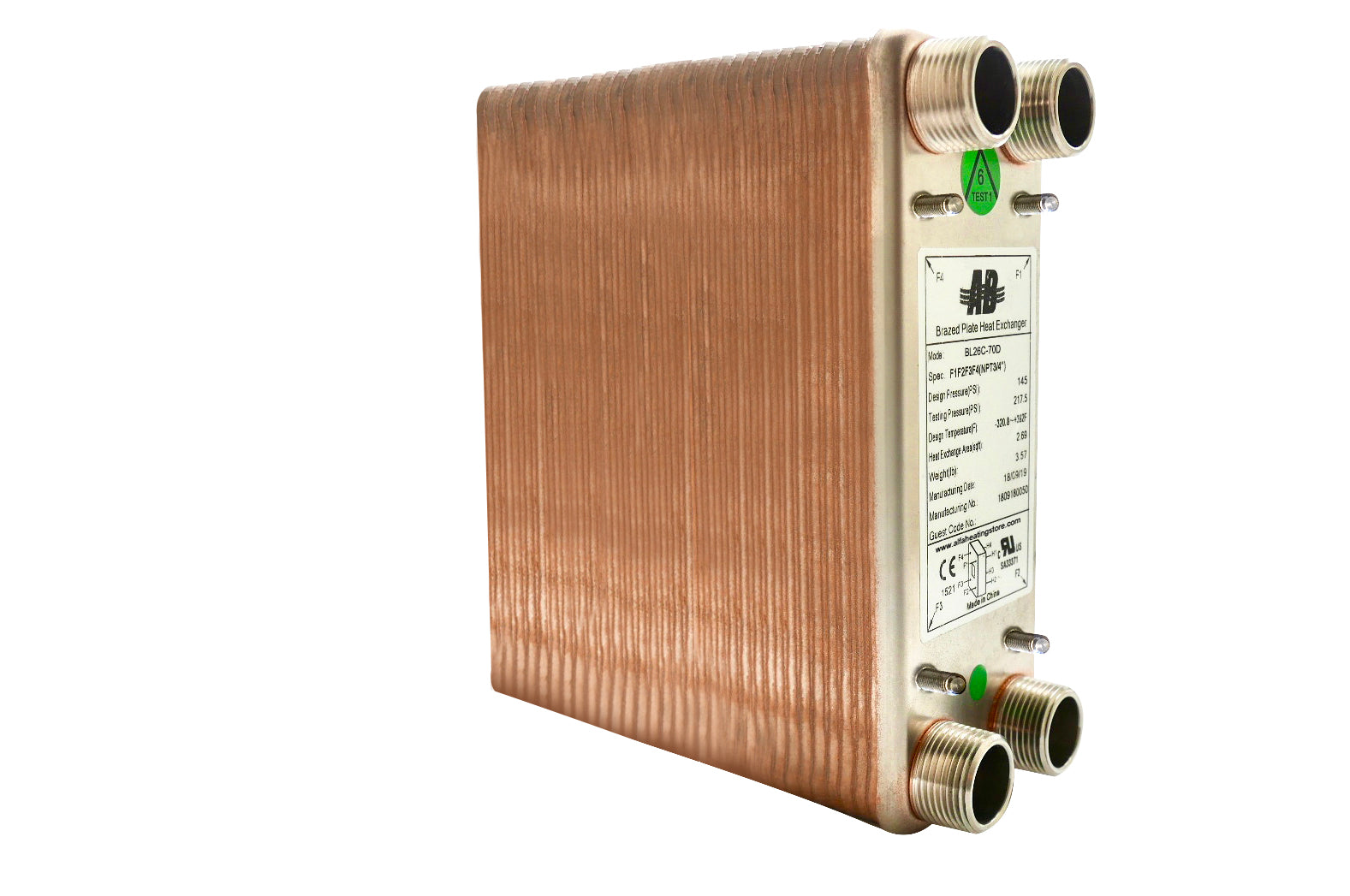

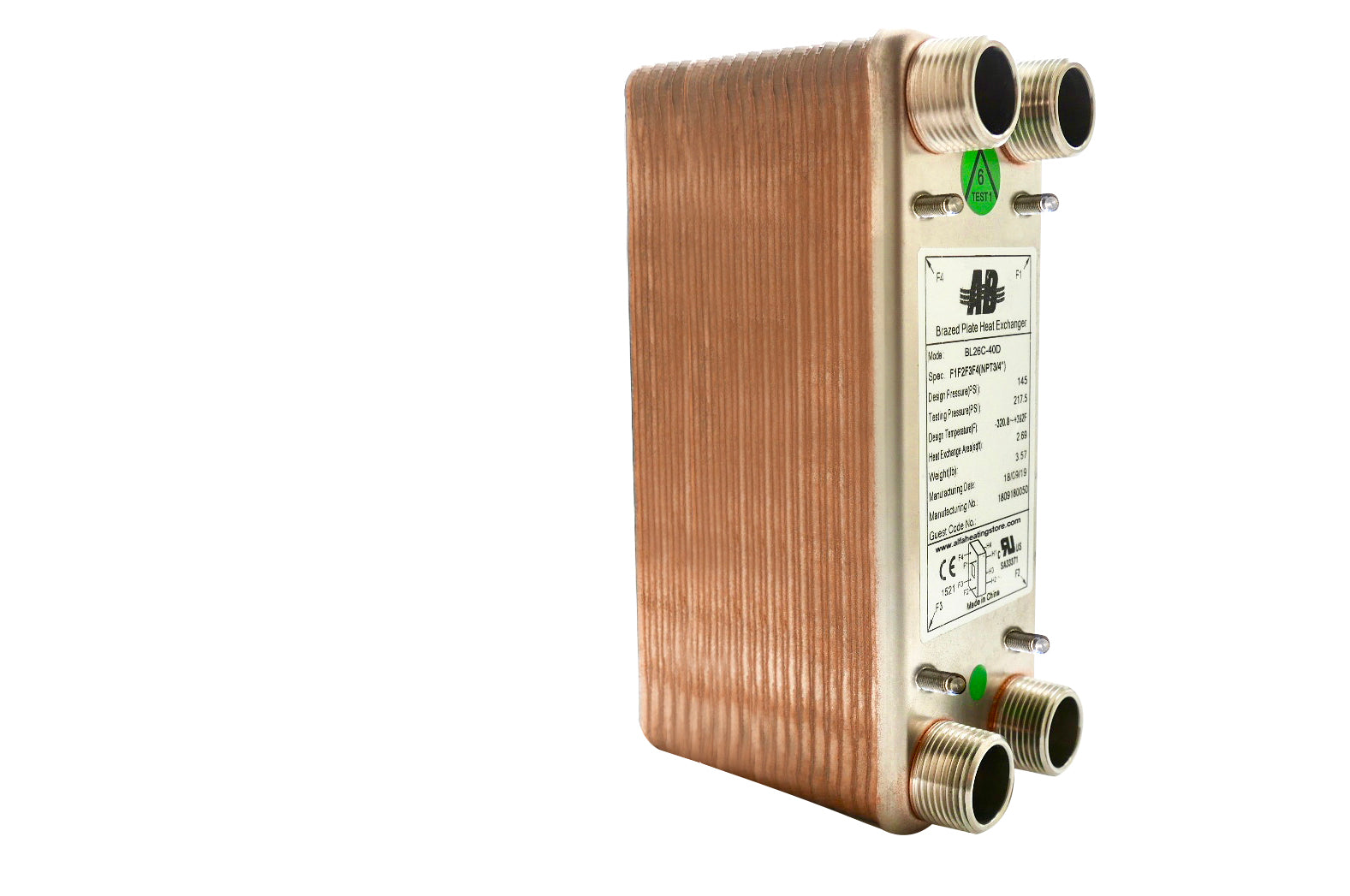

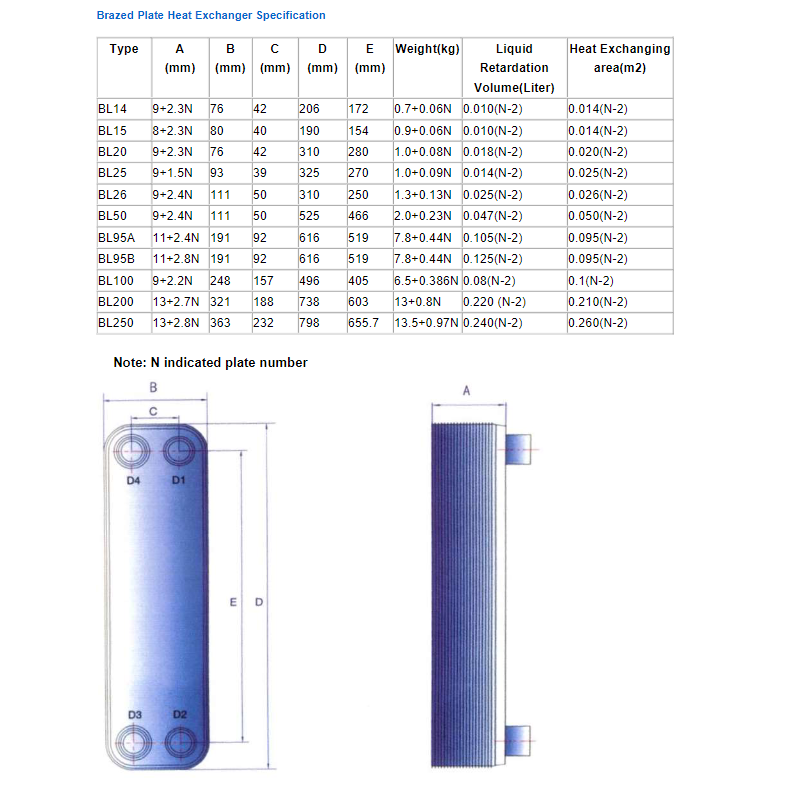

- Brazed Plate Heat Exchangers

- Brazed Plate Condenser

- Shell and Tube Heat Exchangers

- Side Arm Heat Exchangers

- Swimming Pool Heat Exchangers

- Pool Heat Exchangers

- Marine Heat Exchanger

- Electrical Heat Exchangers