A radiator that makes use of the coolant is known as an oil cooler or intercooler. The heat is absorbed by the oil as it cools the object in the issue. It is then routed via a chiller before being returned to the heated item. This is a continuous cycle that keeps your object cool at a constant rate.

Water to air intercoolers or other types is most commonly utilized on performance engines that don't or can't be cooled by water. An oil circulation system used for oiling is frequently modified to allow for this cooling system. It needs a larger oil capacity and higher oil pump flow rate, as well as an oil-air oil cooler.

How Does an intercooler work?

When air is compressed, it becomes very heated very rapidly. As a result, the temperature rises, and the oxygen concentration (density) decreases. An intercooler offers a denser, more oxygen-rich air to the engine when the air is chilly. As a result, combustion is improved by enabling more fuel to be consumed.

Types Of Oil Coolers and Intercoolers available at WiseWater Alfa Heating Company

- Air to Air - By sending compressed air through a network of tubes, the Air-to-Air intercooler removes heat. Heat is transported via the tubes and cooling fins as compressed air passes through the intercooler. The cold air absorbs heat from the cooling system as it travels at high speeds.

- Air to Water - Water is used as a heat transfer agent in an Air-to-Water intercooler. The air to water intercooler is pumped with cold water, which removes heat from the compressed air as it passes through. After that, the hot water is sent through a second cooling circuit which is usually a dedicated radiator. The cooled compressed air is pumped into the engine at the same moment.

Advantages & Disadvantages of Intercoolers from WiseWater Alfa Heating Company

The Air-to-Air Intercooler has many advantages, including a simpler structure, fewer components, less weight, and the absence of a hydraulic setup, which is required by the Air-to-Water Intercooler.

Since it is air-cooled, one of the downsides of having this system is that it must be installed at the front of the vehicle. As a result, the piping necessary to link the components, as well as the air's path from the compressor to the intercooler and finally to the engine, is somewhat longer. This might have an impact on the engine's performance.

Related Oil Cooling Solutions

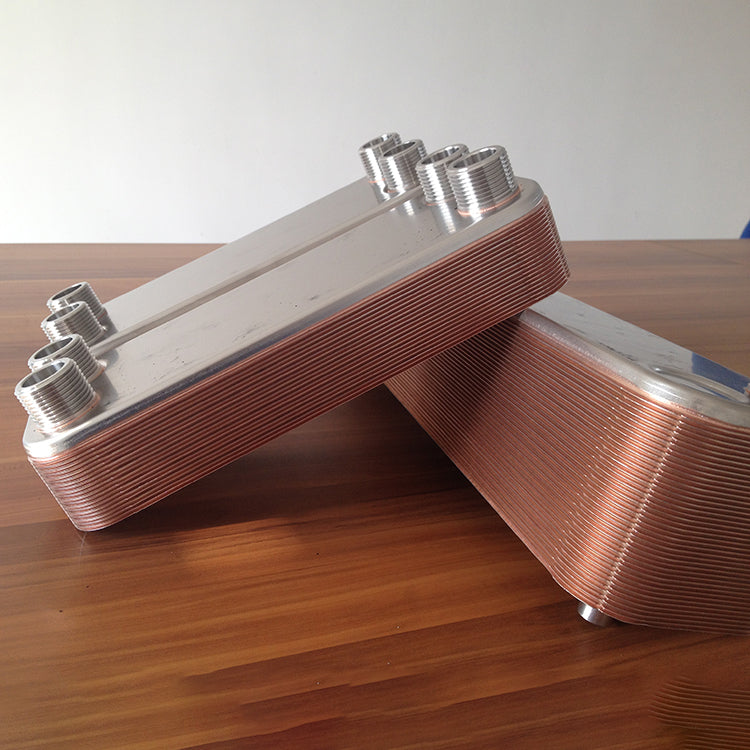

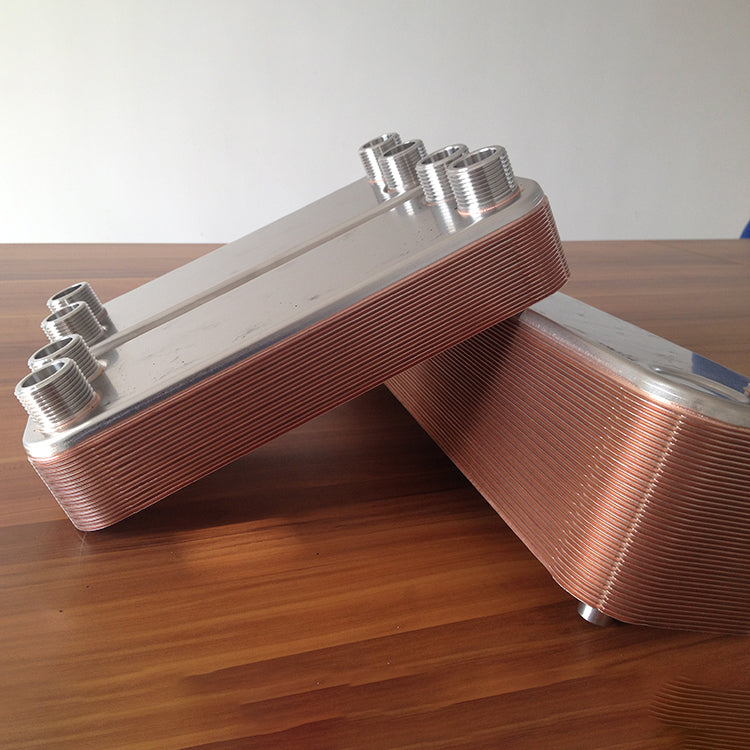

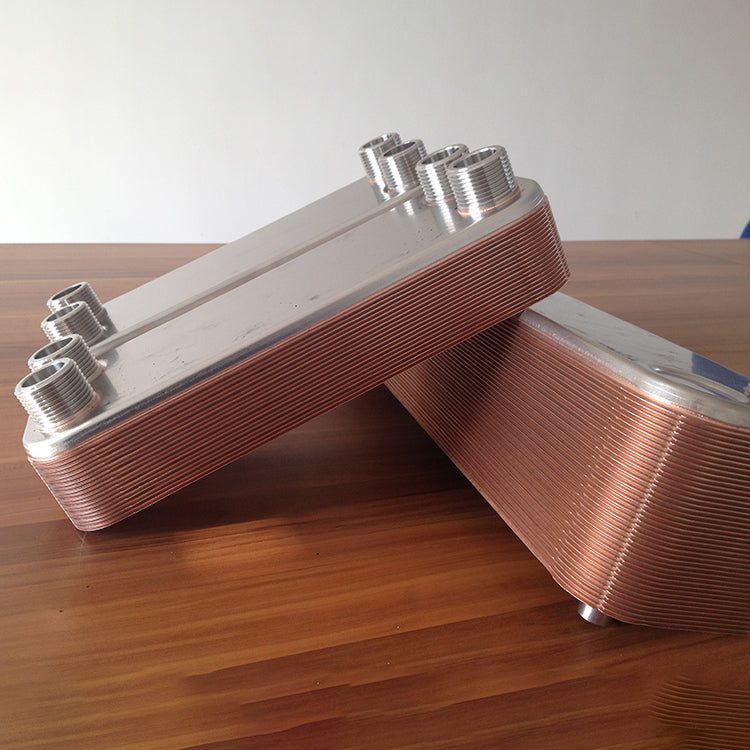

If you're sourcing oil coolers for engines, hydraulic systems, or temperature control units, availability and compatibility are crucial. Alfa Heating offers a wide range of oil coolers and intercoolers designed for both industrial and automotive systems. From water-cooled BPHEs (brazed plate heat exchangers) to marine-grade titanium options, each model is designed to efficiently meet specific cooling requirements.

Every product listed in our collection is selected to meet the thermal control requirements of machinery used in automotive, marine, and manufacturing environments. We provide detailed technical specifications for each item, including connection sizes, material types, and cooling capacities.

Many clients prefer online purchasing due to speed and transparency. On our website, you can explore 17 models, compare options side by side, and filter by application or connector size. Local pickup or international delivery is available, with prompt order processing.

Looking for marine-use stainless steel intercoolers or high-flow shell and tube designs for hydraulic oil systems? Our collection includes both standard and high-capacity models.

If you’re unsure about compatibility, our customer support team can assist with product selection based on your current setup. You can also request custom configurations depending on your oil type and flow rate.

Choosing the right oil cooler depends on the operating environment, fluid type, and cooling method. For temperature control systems in industrial or automotive applications, efficiency and durability come first. Alfa Heating offers oil coolers in two main categories: water-cooled and air-cooled. Each has distinct advantages depending on usage and space constraints.

Water-cooled oil coolers, including our BL and BPHE series, use water as the heat-transfer medium to remove thermal load from oil circuits. These are ideal for systems requiring compact cooling solutions with stable heat exchange, such as hydraulic presses, CNC machines, and high-performance engines.

Shell-and-tube coolers are another popular choice. With their rugged design and seawater compatibility, they are often used in marine settings or for large-scale industrial systems.

In performance vehicles and heavy-duty applications, oil temperature can fluctuate rapidly. This requires coolers with a high surface area and optimized flow paths. Our stainless steel and titanium intercoolers meet these demands while resisting corrosion and wear.

When selecting a unit, consider:

- Flow rate and connection sizes

- Oil type (hydraulic, lube, transmission)

- Ambient cooling environment

Our technical team can recommend the best match based on your equipment type and load profile.

An oil cooler is a heat exchanger that helps manage the temperature of oil used in engines, hydraulic systems, or gearboxes. As machinery operates, oil absorbs heat from moving parts. Without an efficient cooling method, this thermal load can cause premature wear, reduced performance, or complete system failure.

In industrial equipment, oil maintains pressure, lubricates components, and helps dissipate heat. When oil temperatures exceed safe limits, it can lose viscosity and degrade. This compromises lubrication and leads to mechanical issues. An oil cooler prevents this by transferring heat away from the oil and maintaining optimal operating conditions.

In automotive systems, especially in turbocharged or high-performance engines, oil plays a critical role in both lubrication and thermal management. Intercoolers and oil coolers reduce intake air temperature and stabilize oil temperature during rapid load changes.

Marine engines and transmission systems also rely heavily on coolers to handle variable conditions like seawater exposure, changing loads, and confined installation spaces. Our marine oil coolers are built with corrosion-resistant materials like SS316L and titanium to extend service life.

Proper cooling isn’t just about temperature control. It directly affects system longevity, energy efficiency, and maintenance intervals. Selecting the right oil cooler supports smoother operation and fewer breakdowns.