Regular maintenance is crucial for keeping any heat exchanger functioning efficiently over time. Ignoring small issues can lead to costly downtime and reduced performance. In this guide, you’ll find clear, practical steps to maintain your plate and frame heat exchanger, brazed plate heat exchanger, and hydraulic heat exchanger for consistent results.

Check Connections and Seals on a Regular Schedule

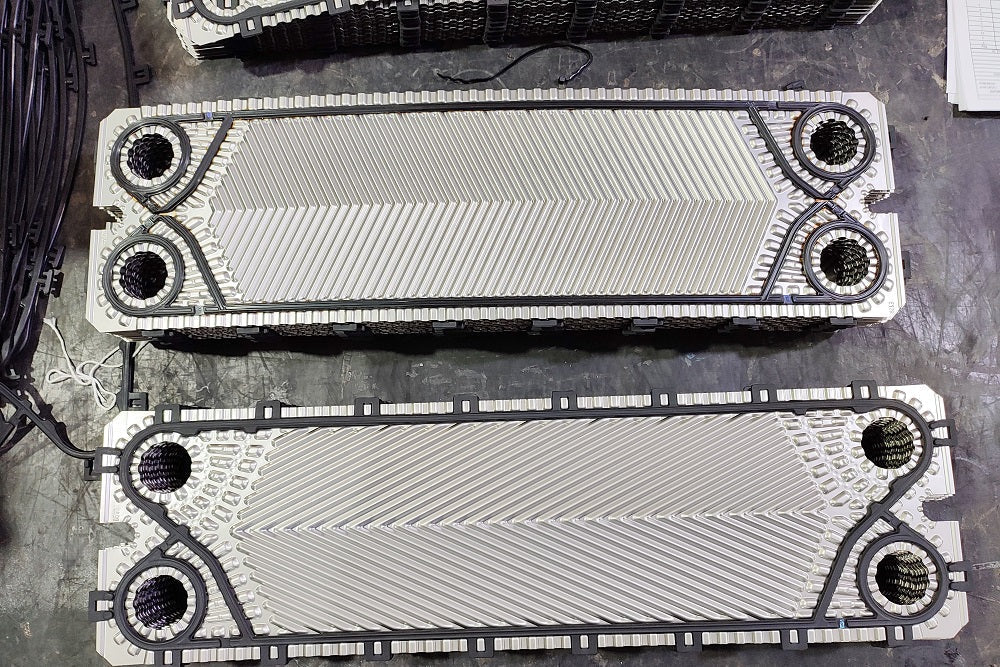

Even the most durable plate-and-frame heat exchanger relies on solid connections and properly fitted gaskets. If a seal loosens over time or a connection begins to leak, the system’s efficiency can drop significantly. This might not seem like a big issue at first, but over weeks or months, it can reduce performance and increase operational costs.

Visual inspections = early problem detection

Pressure loss = possible leak or fouled surface

Make it a habit to:

- Inspect visible connections monthly

- Look for any moisture around seals or joints

- Listen for irregular sounds that could indicate a flow issue

These simple checks can prevent more serious repairs later. This applies whether you’re using a brazed plate heat exchanger, a gasketed unit, or a hydraulic heat exchanger in a demanding industrial setup.

Clean the Plates Without Damaging the System

Fouling is a common issue with any plate and frame heat exchanger, especially in areas with hard water or inconsistent fluid quality. Over time, sediment, minerals, and biological material can build up on the internal surfaces, reducing heat transfer efficiency.

Cleaning too aggressively = plate damage

Using the wrong solution = seal degradation

Use cleaning methods tailored to your specific system:

- CIP (Clean-In-Place): For systems that allow internal circulation of cleaning solutions.

- Manual Cleaning: Disassemble and rinse plates with non-abrasive materials.

- Approved Chemicals Only: Avoid harsh agents that damage gaskets or corrode metals.

This is particularly important for sanitary heating and cooling applications where hygiene is critical.

Don’t Overlook the Circulating Pump

Every heat exchanger relies on fluid movement to function properly. A weak or failing circulating pump leads to poor heat transfer, inconsistent performance, and increased stress on the system.

Signs of underperforming pumps:

- Reduced flow rate through the brazed plate heat exchanger

- Uneven temperatures in zones relying on the hydraulic heat exchanger

- Increased energy usage without noticeable gains

Keep the pump clean and lubricated (if required), and inspect for wear on the impeller and seals. Replacement may be more cost-effective than attempting to overhaul an old pump that has exceeded its life expectancy.

Discover our most popular product categories – find what you need today!

- Air to Water Heat Exchangers

- Water to Air Heat Exchangers

- Plate Heat Exchangers

- Oil Coolers & Intercoolers

- Tankless Water Heaters

Monitor Temperature Differentials

One of the clearest signs that your plate and frame heat exchanger needs attention is a drop in its thermal performance. A good rule of thumb is to regularly check the temperature difference between the input and output on both sides.

Stable temperatures = consistent system efficiency

Large drops = fouling, flow issues, or mechanical fault

If you’re using the exchanger for sanitary heating and cooling, such as in food or pharmaceutical applications, even slight temperature fluctuations can lead to performance issues or safety concerns.

Keep records of your temperature readings and establish a baseline for future reference. That way, any deviation becomes easier to spot and act upon more quickly.

Check for Vibration or Unusual Noise

Systems under constant use can develop mechanical issues that aren’t visible but are audible or physical. A hydraulic heat exchanger mounted near pumps or compressors might pick up excess vibration, which, over time, can loosen plates or weaken joints.

Vibration = long-term component fatigue

Noise = possible flow restriction or debris

Do this monthly:

- Feel for vibration on the housing

- Check mounts and brackets for stability

- Listen for new or louder noises

In a brazed plate heat exchanger, internal cracking can occur if temperature or pressure spikes coincide with excess vibration. Keep this in mind during periods of high operational activity.

Schedule Maintenance Before Problems Start

Waiting until a plate and frame heat exchanger fails is never a cost-effective approach. Preventive maintenance reduces total downtime and increases the lifespan of your system. This is especially important when your setup supports critical systems, such as sanitary heating and cooling, in a production environment.

Plan service checks based on:

- Hours of operation (e.g., every 2,000 hours)

- Seasonal shifts in system load

- Pressure drops across the unit

If your circulating pump or exchanger is more than five years old, it’s worth checking whether newer models could improve energy efficiency or reduce the need for service.

With over 20 years of experience working with heating systems, Alfa Heating Supply combines in-house manufacturing in the USA with deep technical expertise to help businesses maximize the performance of their systems.

Use the Right Fluid and Monitor Its Condition

Using the wrong working fluid in a plate and frame heat exchanger or brazed plate heat exchanger can accelerate wear or cause corrosion. Even approved fluids can degrade over time or become contaminated. Monitoring fluid quality is just as important as monitoring pressure or flow.

Poor fluid = fouled plates + internal corrosion

Clean, stable fluid = longer system life

Be sure to:

- Use the fluids recommended for your specific exchanger

- Monitor pH, conductivity, and visual clarity

- Replace or filter the fluid when it shows signs of degradation

This is especially relevant in sanitary heating and cooling applications, where fluid contamination can lead to compliance issues.