Keep your compressed air system running efficiently with brazed plate air dryers. These units help reduce heat, protect equipment, and improve airflow. Easy to install and reliable in daily use. Choose a durable solution that fits your setup and supports smooth operation. Browse our models and find the right match for your needs today.

Enhanced Performance for Demanding Air Systems

Efficient temperature control is critical to maintaining long-term system performance. Overheating in compressed air systems decreases energy efficiency and introduces risks to equipment longevity. Investing in a purpose-built air cooling system ensures that thermal buildup is reduced while your operations run uninterrupted.

At Alfa Heating Supply, we offer specialized brazed plate solutions engineered for precision cooling. Their compact design and high thermal conductivity make them an ideal choice for industries that rely on stable, clean air delivery. If your current system is experiencing inconsistent flow or excess heat retention, it may be time to upgrade to a more efficient thermal solution.

Our units are compatible with standard configurations, making them easy to integrate. They’re built to deliver reliability over long-term use—day after day, shift after shift. Here’s what makes these heat exchangers stand out.

Understanding the Role of the Brazed Plate Air Dryer

A brazed dryer protects equipment by removing heat from compressed air before it reaches critical components. This cooling process also supports moisture control, which can reduce the risk of corrosion or contamination downstream.

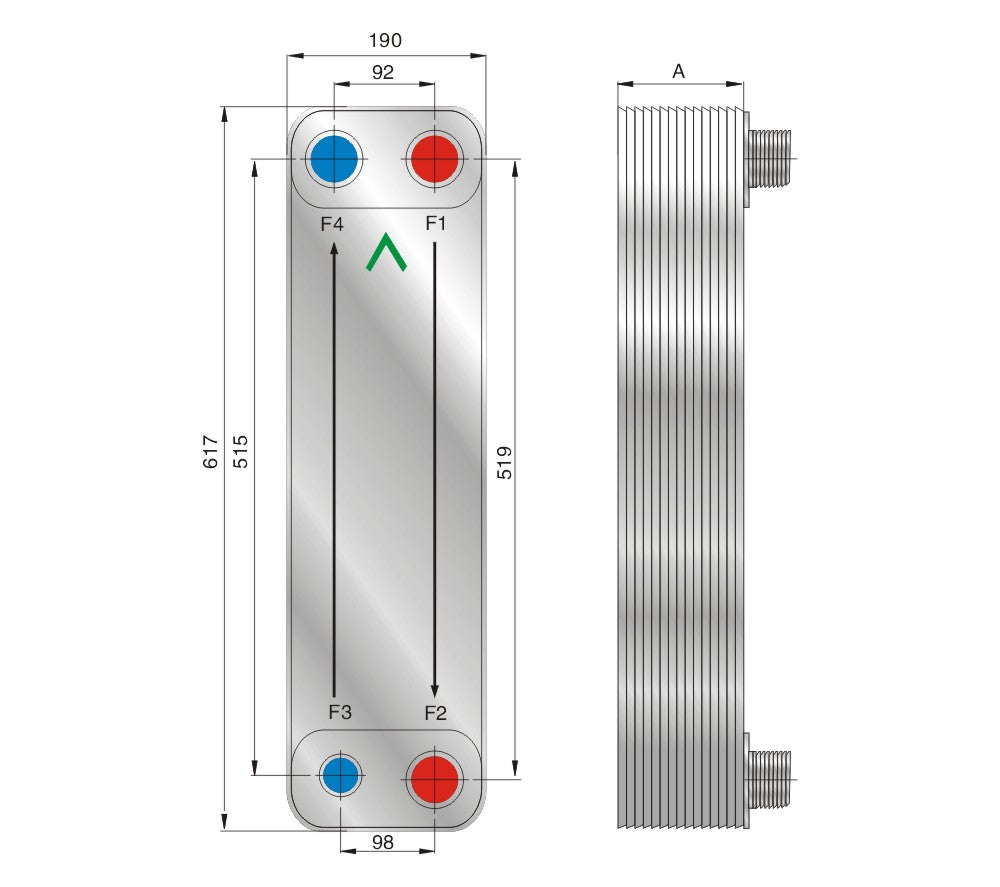

These units are built with stacked metal plates that allow alternating hot and cold fluid paths, maximizing heat transfer in a small footprint. Their compact size makes them suitable for installations where space is limited, but performance is still a top priority. More specifically:

- The brazed design eliminates the need for gaskets or seals, reducing failure points

- Copper brazing improves thermal conductivity and corrosion resistance

- All units are engineered for high-pressure environments

In a typical compressed air unit, the dryer ensures that your system not only cools efficiently but operates within safe thermal parameters, increasing system life and decreasing the likelihood of pressure loss.

Built with 99.9% Copper Brazing for Optimal Efficiency

Material quality directly affects thermal performance. Our units are constructed with 99.9% copper brazing, ensuring high conductivity and resistance to corrosion. This results in more stable performance across the component's operating life and fewer issues with wear or leakage.

Why does copper matter in this context? Higher thermal conductivity = more efficient cooling and reduced energy demand. That translates into faster heat removal and less strain on your primary components.

These features aren’t just technical—they’re practical:

- Minimal maintenance requirements over time

- Reduced operating noise compared to traditional units

- Compact installation options to save on space

A plate dryer with copper brazing isn’t just an upgrade—it’s a solution that pays for itself in performance and system protection.

Designed for Compatibility with Compressed Air Units

Integrating new components into existing systems can often lead to complex adjustments. Our heat exchangers are engineered for seamless compatibility with most standard compressed air unit configurations, simplifying installation and replacement.

Every component is tested to withstand high operating pressures and aggressive thermal cycles, making them ideal for industrial and commercial settings where operational reliability is critical. These heat exchangers are designed to support:

- Multi-shift operations and heavy-duty equipment

- Clean room or moisture-sensitive processes

- Configurations requiring vertical or horizontal mounting

Our models offer flexibility for system designers and maintenance professionals by supporting both new builds and retrofit scenarios.

Reliable Operation with Minimal Maintenance

Once installed, these brazed plate dryers operate with little to no manual intervention. Their design contains no internal moving parts, reducing mechanical failure risk and simplifying long-term upkeep. This makes them well-suited for environments where system uptime is essential, and technician access is limited.

Because there are no gaskets or replaceable seals, maintenance costs stay low. This improves both the return on investment and the predictability of your operation. The performance benefits of a brazed dryer extend well beyond energy savings—they also include stability and confidence in system design.

Maintenance schedules become simpler, and system audits show fewer issues related to inconsistent cooling or component stress.

Compact Design, Scalable Across Applications

The compact footprint of each air dryer we offer allows for easy integration into systems with space constraints. These units are built to be space-efficient while still delivering maximum heat transfer across the fluid paths.

This adaptability makes our solutions attractive across various industries, including automotive, food production, CNC machining, and general manufacturing. Their ability to scale with operational demands means you can start with a single unit and expand without overhauling your existing layout.

And because of their sealed, maintenance-free structure, they are particularly useful in settings where uninterrupted operation is a must.

Lower Operational Risk = Better Long-Term Efficiency

Stability in heat exchange directly supports the health of your overall compressed air infrastructure. When cooling is inconsistent, operational pressure and temperature control are compromised. This leads to increased wear and, ultimately, higher operating costs.

Our air cooling system components are optimized to prevent these issues by maintaining efficient thermal flow over time. Once integrated, they allow for more predictable system behavior—critical for operations that can’t afford unexpected downtime.

A properly selected plate dryer can extend the life of air compressors, protect downstream tools, and reduce energy draw across the board. Because our units are built to perform in both high- and low-volume systems, you can trust their output will meet your day-to-day operational needs without compromise.

Choose Lasting Reliability for Compressed Air Systems

The performance of your cooling unit plays a significant role in overall system health. That’s why choosing the right air dryer isn’t just about temperature management—it’s about preventing costly issues before they arise.

Our brazed models offer a reliable, space-saving solution for engineers, technicians, and buyers seeking long-term stability without unnecessary complexity. Each compressed air unit you build or upgrade with our heat exchangers brings measurable improvements in airflow quality, temperature regulation, and pressure balance.