Looking for a space-saving way to handle condensation in your system? Our brazed plate condensers are reliable, efficient, and simple to install. They are used in HVAC, refrigeration, and industrial cooling. Explore the options we offer and choose the right plate condenser for your setup and performance needs.

What Makes a Brazed Plate Condenser a Good Choice

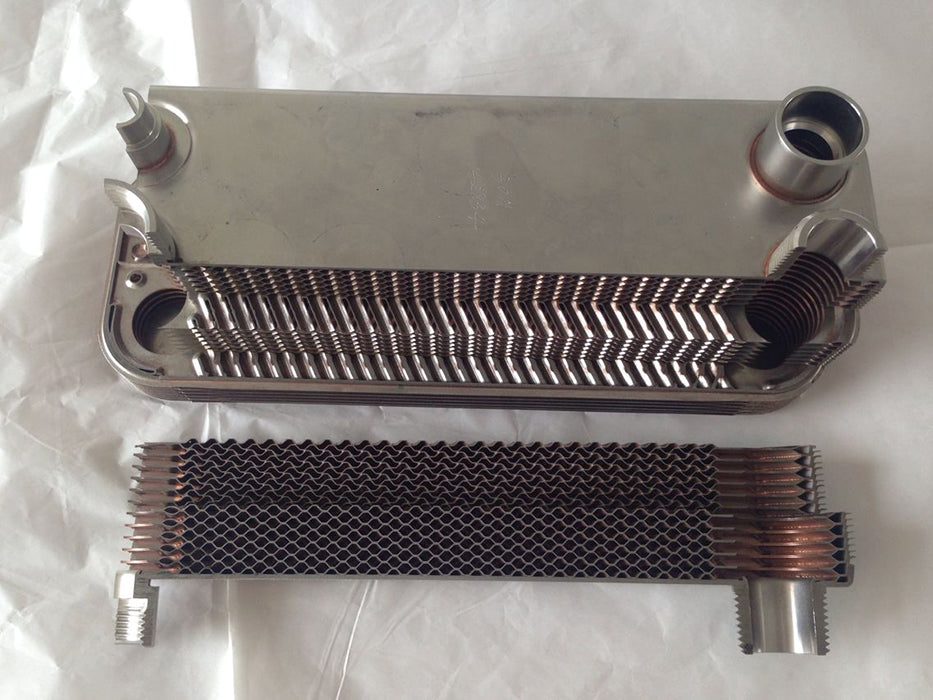

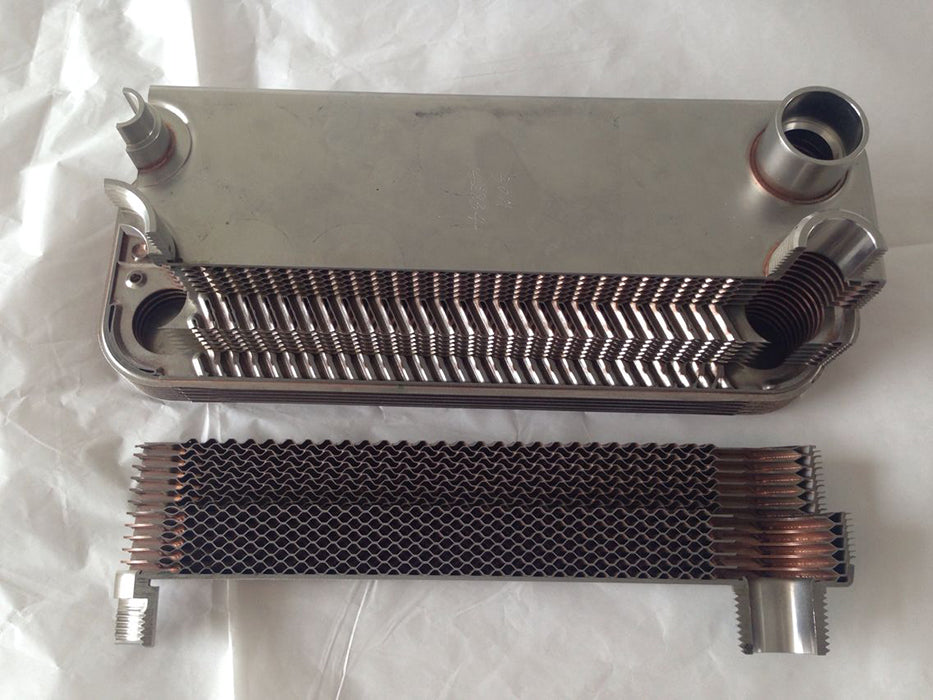

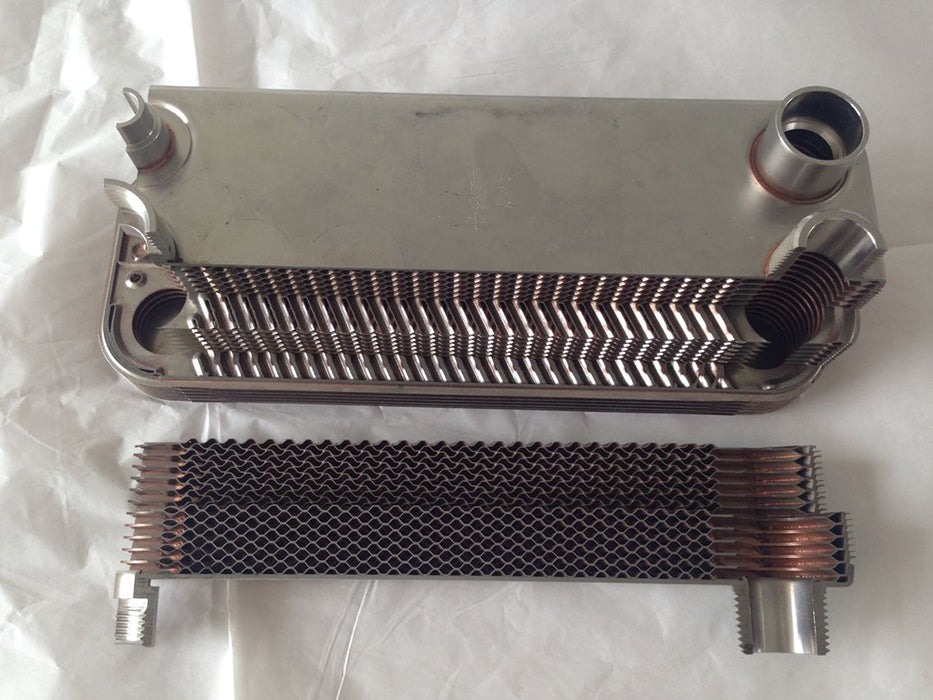

If you’re working with systems that need efficient heat exchange in a compact space, you’re likely already considering a brazed plate solution. These units are designed for high thermal performance in small footprints. The construction method uses vacuum brazing, which creates strong, leak-proof joints without gaskets or additional seals. This ensures minimal maintenance and high reliability.

A brazed condenser operates efficiently even under demanding temperature and pressure conditions. These systems are often used in HVAC, refrigeration, and industrial cooling because they handle condensation tasks exceptionally well. Their efficiency-to-size ratio makes them ideal when performance matters but space is limited.

Tighter installations mean more flexibility in system design, making these units a popular choice for retrofits and new installations.

Applications That Benefit from a Plate Condenser

A plate condenser brings solid advantages in any environment where compact, reliable condensation is essential. From residential chillers to complex industrial processes, its versatility helps reduce system complexity and improve energy use.

Because these condensers transfer heat directly through thin, corrugated metal plates, the contact surface area is maximized. That means fast and efficient heat exchange without unnecessary bulk. The small footprint is not just convenient—it’s often a requirement in systems where space is at a premium.

HVAC installers, OEMs, and system designers often choose brazed plate systems because of their durability and thermal efficiency. More output per square inch = more room for other components in your setup.

High Durability and Low Maintenance Over Time

Choosing a brazed condenser means investing in a long-lasting solution. The brazing process creates a solid bond between plates, making the entire unit resistant to high pressure and thermal cycling. These units don’t require regular disassembly, which cuts down on maintenance time and costs.

Because no gaskets are involved, there’s less chance of leaks or failures, even during peak operation. You install it once, and then it runs reliably for years.

This rugged design is especially valuable in demanding applications like cooling, refrigeration, and heat pump systems. In terms of product lifespan and total cost of ownership, these units consistently outperform other alternatives.

Still, their biggest advantage may be how they simplify installation and system design.

Easy Integration with Various System Designs

A compact condenser fits easily into tight spaces and can be installed horizontally or vertically, depending on your system’s needs. Traditional cooling equipment lacks that kind of flexibility.

Installers appreciate the lighter weight and smaller size, which means faster setup and easier transport. These units help reduce overall volume and simplify connections even in larger systems.

Because a compact condenser offers high thermal performance, you can often reduce the size of pumps and piping needed to support your system. That results in lower operating costs and improved system efficiency.

Efficiency of Plate Cooling Units

A plate cooling unit directs hot fluid over a series of metal plates while a cooler medium flows on the opposite side. This direct contact between the fluids through the plate walls ensures rapid and consistent temperature change.

These cooling units work exceptionally well with refrigeration and condensing applications, where quick heat transfer is key. Because of the large surface area inside a small volume, you get top-tier performance without the bulk of a shell-and-tube design.

Thanks to this efficient layout, a plate cooling unit often replaces larger, heavier equipment with no performance loss—sometimes even gaining an edge in responsiveness and thermal control.

Why Professionals Choose This Solution Again and Again

Reliability, performance, and ease of use—that’s why experts keep coming back to brazed plate and plate condenser models for their systems. These solutions check all the boxes, whether it’s HVAC installations, commercial chillers, or industrial cooling.

High efficiency + compact size = a smart investment for both new builds and system upgrades. And because they come in different sizes and connection types, there’s almost always a model that fits your technical needs.

The combination of strength, thermal output, and design flexibility makes every brazed condenser a reliable long-term solution. If you need a dependable, cost-effective component for your heat exchange system, a plate cooling unit is a strong contender.

FAQ

A brazed plate condenser is a type of heat exchanger designed to remove heat from a vapor and convert it into a liquid. It achieves this by using a series of thin, corrugated metal plates stacked together and permanently joined through a vacuum brazing process. This method of construction eliminates the need for gaskets, allowing for a more compact and leak-resistant unit.

What makes it so practical is the high surface area created between plates. This allows for very efficient thermal transfer in a small space. Each unit is pressure-resistant, compact, and designed for operation in demanding conditions. The rugged design and all-metal construction ensure that you don’t need to worry about common failure points, such as seals or joints.

Compact design = more installation flexibility. These units are frequently selected for use in HVAC systems, chillers, heat pumps, and industrial cooling applications. System designers often turn to this technology when space is limited but performance still matters.

Brazed plate condensers are designed to efficiently handle condensation duties across various systems. By condensing vapor using direct metal-to-metal heat transfer, they remove heat quickly and efficiently. Their construction also makes them suitable for a wide range of fluids, depending on the application and system layout.

If your setup demands reliability, efficiency, and minimal maintenance, this type of condenser offers a well-balanced solution without adding complexity.

A brazed plate condenser works by directing hot vapor across a network of stainless steel plates. On the other side of those plates, a cooler fluid (usually water or glycol) flows in the opposite direction. The heat from the vapor is transferred through the metal plates and absorbed by the cooler fluid, causing the vapor to condense into a liquid.

Each plate in the unit is patterned to create turbulence as the fluids move. This increases the heat transfer rate, making the system more efficient. Because the plates are brazed together, heat transfers directly between the surfaces without the need for seals or additional components.

This high-efficiency layout enables rapid temperature changes, minimal thermal loss, and seamless integration with various system types. It’s one reason these units are often used in cooling loops, chillers, and heat recovery applications.

A larger surface area results in faster heat transfer. This basic equation drives the performance benefits behind plate-style condensers. Instead of relying on large, bulky coils or shell-and-tube systems, a brazed unit achieves better results in a fraction of the space.

Another advantage is durability. The brazed construction withstands continuous use and thermal cycling. You don’t need to disassemble it for regular servicing, and its performance remains consistent over time.

Whether installed horizontally or vertically, these units fit neatly into compact spaces and work reliably under pressure.

Yes, a brazed plate condenser is commonly used in refrigeration systems, including commercial chillers, residential heat pumps, and industrial freezers. Its compact size and strong performance make it ideal for systems that demand efficient heat removal in tight layouts.

In a refrigeration setup, the condenser’s job is to take vapor refrigerant from the compressor and remove enough heat to turn it into a liquid. The brazed plate design accomplishes this quickly and efficiently. The heat from the refrigerant is transferred through the plates and carried away by a cooling fluid, typically water or a water-glycol mixture.

Faster condensation results in lower energy use and improved cooling output. Such a result is crucial in refrigeration systems, where energy efficiency has a direct impact on long-term operating costs.

These condensers also facilitate the design of flexible, space-conscious systems. You’ll find them used in systems that require lightness, reliability, and ease of service—especially in tight mechanical rooms or mobile refrigeration units. The ability to mount them in multiple orientations helps simplify piping layouts and reduce installation time.

Unlike older condenser designs, a brazed plate version delivers high thermal efficiency without the bulk. This makes it a preferred solution in both OEM refrigeration builds and retrofit installations.

Related Heat Exchangers

- Air to Water Heat Exchangers

- Water to Air Heat Exchangers

- Water to Water Heat Exchangers

- Plate Heat Exchangers

- Plate Heat Exchangers (Copper Brazed)

- Brazed Plate Heat Exchangers

- Shell and Tube Heat Exchangers

- Side Arm Heat Exchangers

- Swimming Pool Heat Exchangers

- Pool Heat Exchangers

- Marine Heat Exchanger

- Electrical Heat Exchangers