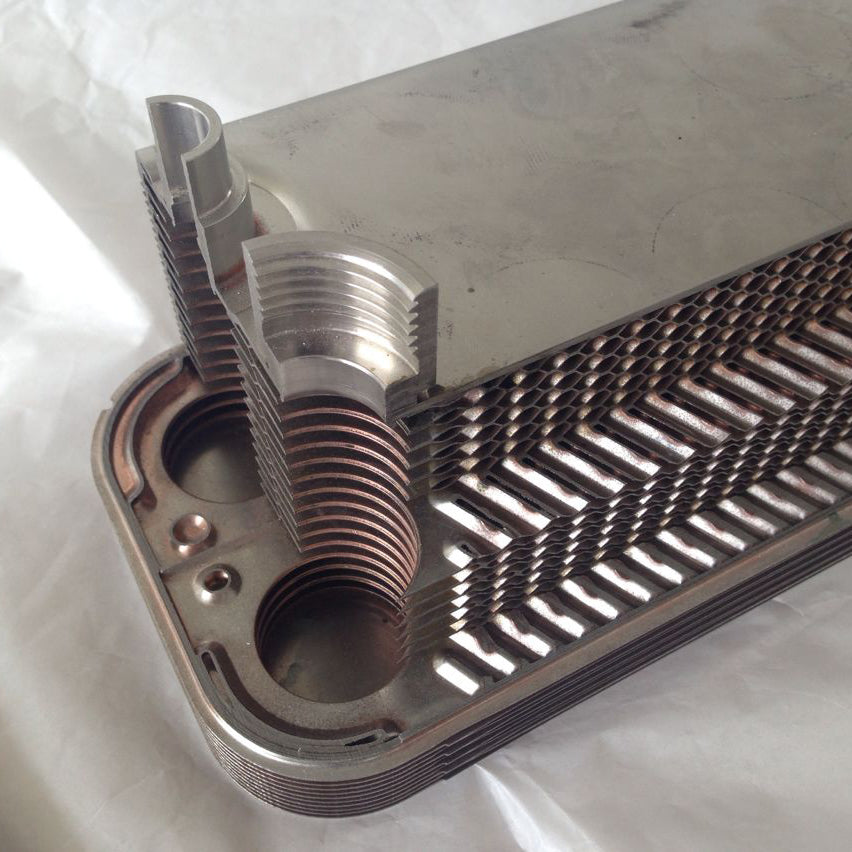

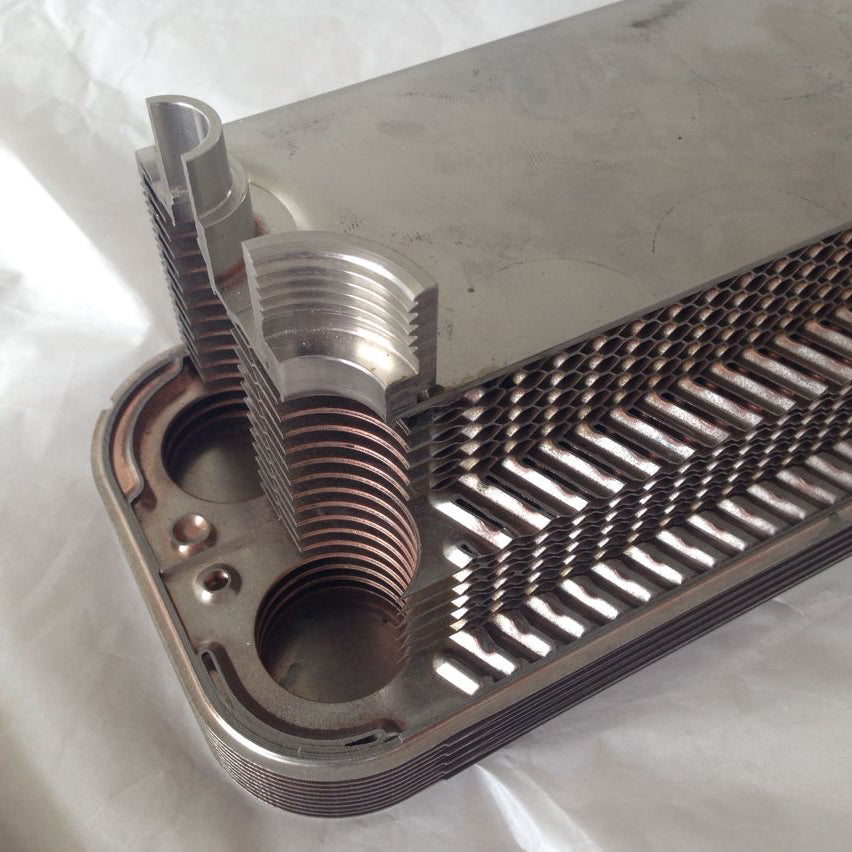

Evaporators help control temperature by removing heat in cooling systems. These plate heat exchangers work with R22 and are easy to install. Ideal for HVAC and industrial use. Check specs to find the right fit for your system and improve performance. Explore our options and choose the model that meets your setup.

Understanding the Function of an Evaporator

A high-performing evaporator unit is essential to any well-designed cooling or refrigeration system. It absorbs heat from the surrounding medium, allowing the refrigerant to evaporate and lower the temperature in a controlled, efficient process. In plate heat exchangers, this means more precise thermal management and reduced energy waste.

Our units are designed for systems using R22 refrigerant, with threaded NPT pipe connections to support simple installation. Their compact design helps fit into various industrial and commercial environments where performance and space optimization are both priorities.

Choosing the correct evaporator unit directly impacts system performance:

- Better evaporation control = more stable system temperatures

- Accurate sizing = fewer breakdowns and improved energy efficiency

These units support heat absorption in cold rooms, beverage processing, and industrial cooling—applications where consistency is essential. As your cooling demands grow, reliable evaporation will remain a key part of system stability.

Cooling Coils and Their Role in System Efficiency

A cooling coil allows the refrigerant to absorb heat efficiently from the air or liquid passing over it. The design maximizes surface area and turbulence in plate-style systems, significantly boosting heat transfer speed. That’s how stable temperature output is maintained even during fluctuating load conditions.

Each of our plate heat exchangers incorporates features that enhance performance:

- Wide surface area for faster energy absorption

- Robust channel layout for even refrigerant distribution

These systems allow consistent output across different industries, including food processing and HVAC installations. They also operate under controlled pressure levels, making them suitable for continuous, long-term use.

When airflow, pressure, and fluid dynamics rely on a single component, the cooling coil becomes more than just a part—it becomes a key performance factor.

Thermal Evaporation for Accurate Temperature Control

A thermal evaporator enables high-precision cooling across various industrial systems. It supports exact heat removal through continuous refrigerant evaporation, which is especially valuable in process industries that depend on controlled operating temperatures.

Our evaporators use compact plate structures designed for efficient phase change—from liquid to vapor—within a small footprint. The benefits of this design include:

- More controlled temperature regulation

- Optimized performance even under changing workloads

A thermal evaporator also minimizes temperature spikes that can cause instability or damage in sensitive environments. This is particularly useful in pharmaceutical and food production lines, where temperature consistency is tied directly to quality standards.

Because our models support R22, they’re compatible with existing infrastructure, giving engineers and technicians working with legacy systems flexibility.

Coil Design and Refrigeration Performance

Every refrigeration coil must balance durability, thermal conductivity, and pressure resistance. In plate heat exchangers, the coil isn’t visible in the traditional sense—but the internal channels perform the same function: guiding refrigerant while absorbing heat with maximum efficiency.

Material quality is key. Our coils are built with corrosion-resistant stainless steel, offering consistent heat transfer without risking leaks or pressure failure. In addition, the spacing of internal plates reduces the likelihood of fouling or flow restriction.

A well-designed refrigeration coil contributes to:

- Faster response to temperature changes

- Improved refrigerant flow and cycle efficiency

These coils reduce compressor load by supporting steady-state operation, helping lower maintenance costs over time. As your system grows, the impact of a high-performance coil will become increasingly important to total efficiency.

Optimizing HVAC Systems with the Right Evaporator

An HVAC evaporator determines how well the system manages airflow, humidity, and thermal balance in HVAC environments. Our plate-based units offer reliable operation under changing load demands while maintaining a compact size and simple pipe connectivity.

The goal is to ensure evaporative cooling occurs at maximum efficiency with minimal system strain. Each HVAC evaporator in our offering is tested for compatibility with refrigerant type, pressure ratings, and temperature range. This ensures seamless integration with broader HVAC setups, including compressors, expansion valves, and fans.

In real-world applications, this translates into:

- Stable temperature control across multiple zones

- Reduced need for manual adjustment or frequent maintenance

If you’re working on HVAC installations in commercial buildings, food storage, or labs, the evaporator is not just a passive component—it’s key to system balance and responsiveness.

Selecting the Ideal Evaporator Configuration

Selecting the correct evaporator = stable output and minimal system disruptions. Here’s what you need to assess before purchasing:

- Pipe size (our models range from 1” to 3” NPT)

- Refrigerant type (all current units are R22-compatible)

- Cooling capacity required for your application

By starting with those three parameters, you can narrow your selection to a model that fits your system’s demands and avoids inefficiencies from under- or oversizing. Overdimensioned evaporators waste energy, while undersized units stress other components, causing wear.

Our plate format simplifies installation, requiring minimal clearance and offering flexibility for vertical or horizontal mounting. Whether your system operates continuously or in batch cycles, these evaporators adapt well to both conditions.

Maintenance Tips and Long-Term Reliability

Even though these evaporators are low-maintenance, regular inspection ensures optimal performance. Keep connections sealed, monitor for refrigerant loss, and clear external surfaces of dust or residue. These steps extend the life of the system and prevent common breakdowns.

Built for industrial durability, our units include strong welds and high-grade materials. A single investment supports long-term service in demanding settings. A plate-style design also helps you access internal components if service is needed.

What this means for you:

- Fewer operational interruptions

- Lower long-term ownership cost

No matter your application, the goal is reliability. Investing in a system that works efficiently—and continues to do so with minimal effort—is the best choice.

Finding industrial evaporators that are both efficient and built for long-term use requires more than just browsing catalog listings. The key is to source from specialized suppliers with technical expertise, proven product compatibility, and a clear understanding of system performance. Alfa Heating provides a dedicated selection of plate heat exchanger evaporators engineered for commercial and industrial environments. All units are available directly through the online store, with transparent pricing in PLN, flexible model options, and detailed specifications for easy comparison.

Each product is listed with full compatibility details, including:

- NPT connection size (from 1" to 3")

- Refrigerant type (all current models are designed for R22)

- Thermal capacity range for industrial applications

Alfa Heating also ensures clear system integration by offering models that fit both new and legacy cooling setups. These evaporators are well-suited for HVAC installations, cold rooms, and process cooling systems where performance consistency is critical. By sourcing from a focused platform like this, users reduce the risk of mismatched components and can rely on products built to perform under pressure.

Stock availability, real-time pricing, and localized currency support make ordering with confidence easier. For system engineers or technicians working under tight project timelines, ordering directly from a specialized provider eliminates guesswork and supports faster implementation.

Before purchasing, compare pipe sizes and heat-load requirements to identify the optimal configuration. If assistance is needed, Alfa Heating provides detailed product descriptions and model comparison tools to guide you.

The most effective evaporators for HVAC and industrial cooling must be compact, compatible, and capable of maintaining stable temperature output even under fluctuating load demands. Plate heat exchanger evaporators deliver high efficiency in smaller footprints, which is why they’re commonly used in cooling-intensive industries such as food processing, pharmaceutical production, and environmental control systems.

What sets high-performing units apart:

- Stainless steel construction for thermal conductivity and corrosion resistance

- Balanced internal plate design for even refrigerant distribution

The evaporators available from Alfa Heating are designed for R22, a refrigerant still widely used in legacy systems. Each model features threaded NPT pipe connections and sizes ranging from 1" to 3", making them compatible with most existing systems. These details are essential when designing for either continuous or intermittent operation.

In HVAC systems, consistent air handling depends on efficient evaporation. Plate heat exchangers maximize surface area and minimize flow resistance, helping maintain pressure balance while avoiding unnecessary compressor strain. For industrial environments, temperature precision is not optional—it directly affects output quality and equipment longevity.

Choosing the best evaporator also requires consideration of long-term reliability. Alfa Heating’s models are built for low-maintenance operation with simple access for inspection and cleaning. This reduces system downtime and supports sustained performance without recurring interventions.

System planners and integrators often select these units because they align with common industry requirements and eliminate the need for customization or retrofitting.

An evaporator absorbs heat by converting refrigerant from liquid to vapor, lowering the temperature within a cooling system. In plate-style systems, this process happens efficiently across a compact internal surface, enabling precise control and minimal thermal loss. These evaporators are key components in both HVAC and industrial refrigeration systems.

The primary applications include:

- Cold storage and food processing

- HVAC systems in commercial buildings

- Process cooling inthe pharmaceutical and chemical industries

In all of these, stability is critical. The evaporator’s role is to remove heat from the medium (usually air or liquid) so the overall system can maintain a desired temperature. Without effective evaporation, cooling systems fail to deliver consistent output, causing spikes, delays, or equipment stress.

Alfa Heating’s plate heat exchangers are designed to meet those demands. The internal structure promotes turbulent flow, improving heat absorption without increasing system resistance. Because each model is built for R22 refrigerant and features welded stainless steel, they are ready for demanding use cases and compatible with many existing systems.

The compact design also helps in tight installations where space is limited. These evaporators can be mounted in various orientations and are easy to integrate into larger systems. With minimal clearance needed, installation becomes faster and less complex.

Evaporators are not just passive components—they actively determine how well a system responds to cooling demands. In environments where precision and uptime are critical, having the right evaporator in place ensures everything else works as intended.