Description

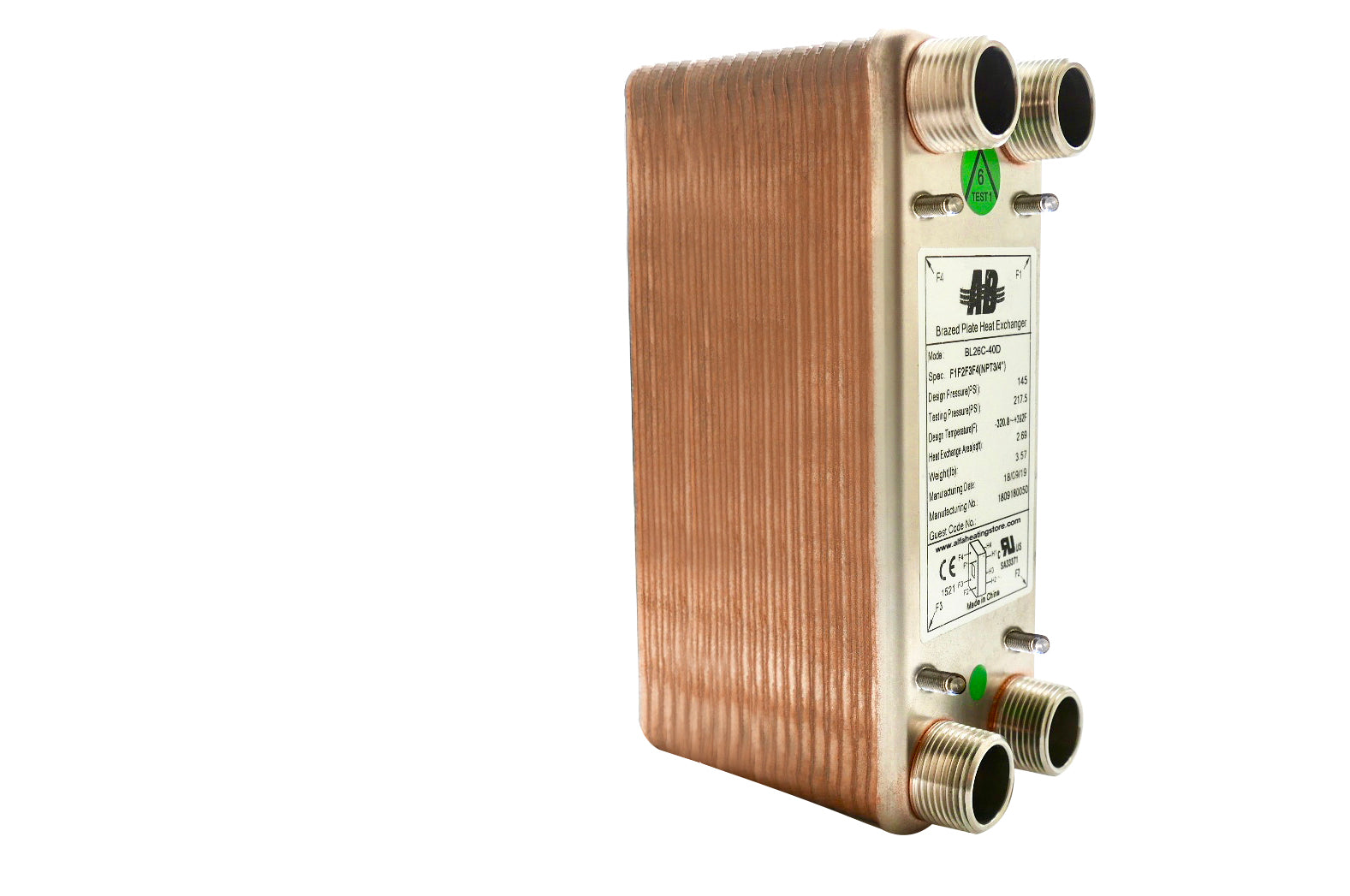

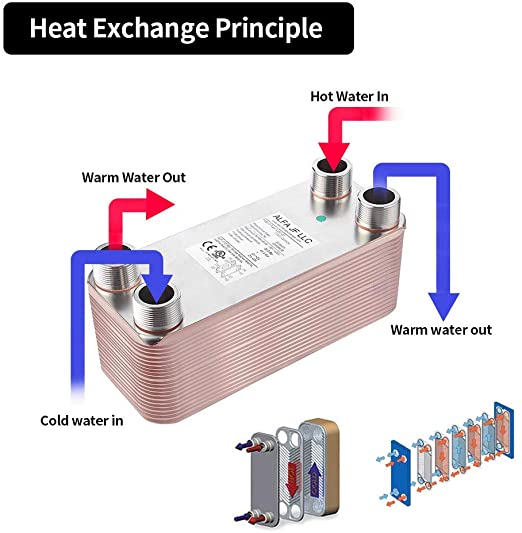

WiseWater Brazed Plate Heat Exchanger has a lightweight and compact design that allows for easy installation and service. When compared to other types, the advantage of this heat exchanger is that it features corrugated plates that produce a highly turbulent flow which allows for a true counter-current exchange. A counter-current flow is the most efficient way of exchanging heat between two fluids. Because of this, and due to the smaller size and reduced material content, Brazed Plate Heat Exchangers can be the most economical heat transfer choice.

- Plate heat exchanger BL26C-40D made of stainless steel 316L, 99.9% copper brazed

- 1 1/4" male fittings connections, 5"x12" dimension

- Depending on the application, the capacity ranges from 380,000 - 530,000 Btu/hr.

- This product has a 1-year warranty against manufacturer defects and is UL listed.

Product Information

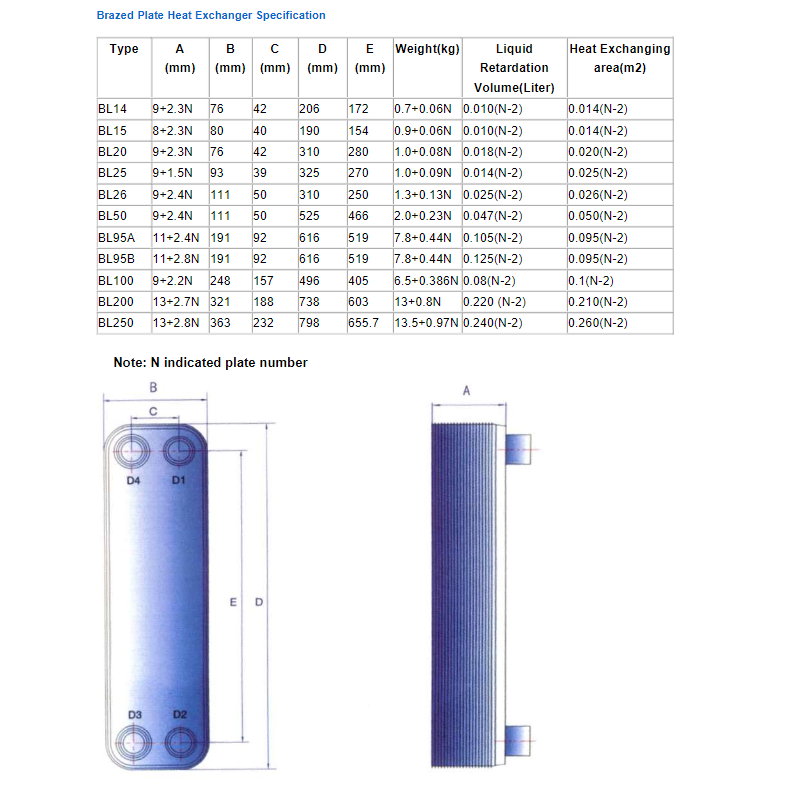

| Model |

BL26C-40D | Fitting Size |

1 1/4" MPT | Materials |

Stainless Steel 316L, 99.9% Copper |

|

Min. |

-310 F |

Max. |

482F |

Dimensions |

5" x 12.2" x 4" |

| Design Pressure |

435psi |

Test Pressure |

653psi |

Weight |

16.5lb |

Application Specifications

| Floor Heating | Domestic Hot Water Heating | Snow Melting |

| 530 kBtu/hr | 430 kBtu/hr | 380 kBtu/hr |

|

26.2 GPM / 26.2 GPM |

24 GPM / 7 GPM (Boiler temp.: 180F Pipes temp.: 40F-140F) |

24 GPM / 27 GPM (Boiler temp.: 180F 50% Glycol temp.: 110F-140F) |

BPHE Brochure.pdf

Limited Warranty of Heat Exchanger.pdf

Instruction Manual.pdf

If you have any special requirements, please fill the Heat Exchanger Sizing and Quote Form.pdf

FAQ and Support

How to protect against freezing:

There are a few ways to help prevent freezing in your heat exchanger:

Using a freeze-protection thermostat and a flow switch in the spare connections (if available) to guarantee a constant water flow before, during, and after compressor operation; use a filter mesh ~1mm; use antifreeze when the evaporating temperature is close to liquid side freezing.

In addition to these freeze prevention tips, try to avoid operating the unit during pump downtime. This product can be used with glycol (50%) for antifreeze purposes.

We have worked with heating systems for over 10 years and are happy to help you with any questions or concerns that you may have. You can email us at info@alfaheating.com or call us at 833 328 6888 for help with your heating projects.