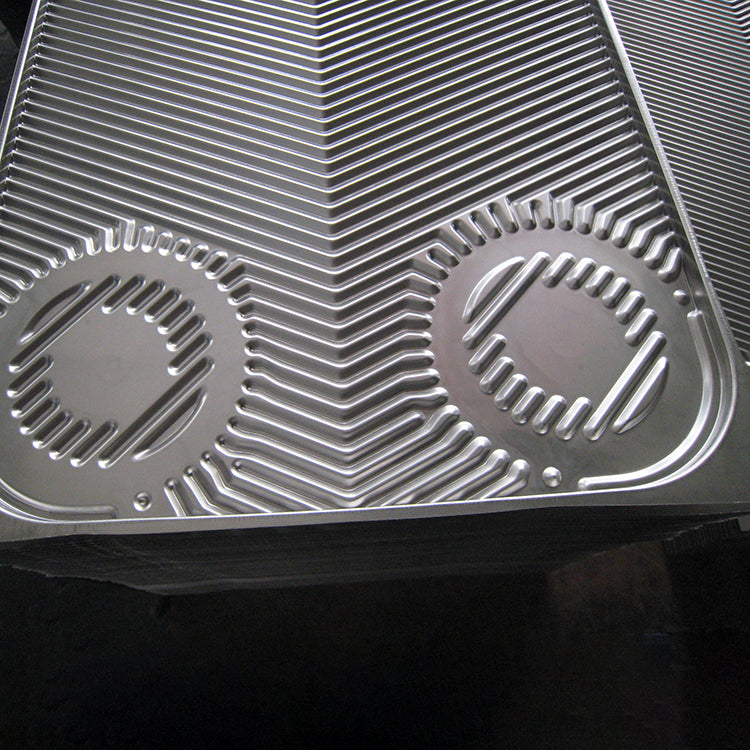

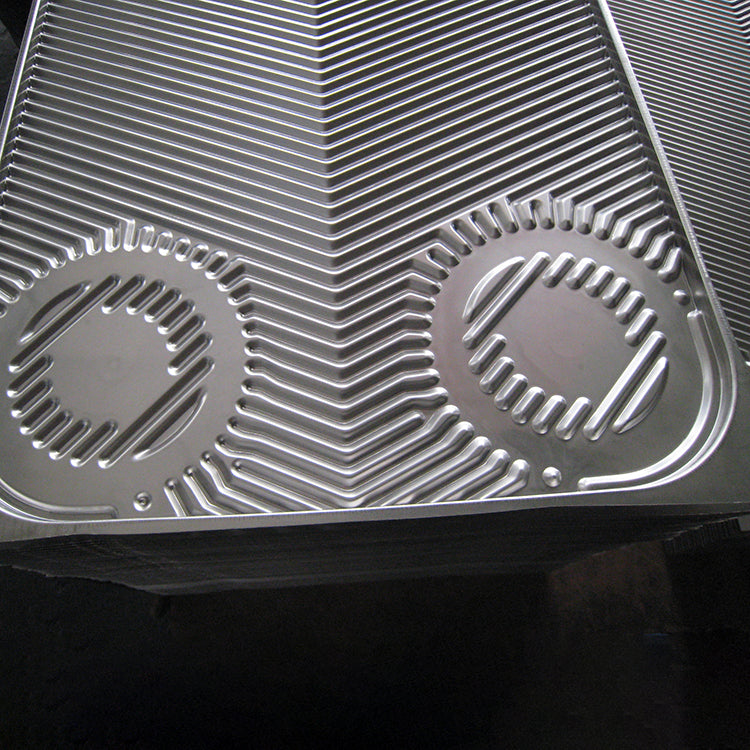

Brazed Plate Heat Exchangers represent the most compact, rugged and cost-effective means of transferring heat in many industrial and refrigerant applications. Plate heat exchangers provide efficient heat transfer in compact equipment with a small footprint - much smaller and more efficient than shell-and-tube heat exchangers. Plate heat exchangers are designed to optimize heat transfer, because the corrugated plates provide by far the greatest surface area through which the heat can be drawn from one gas or liquid to the other.

Flexible design and are easy to service and maintain. Precision heat transfer, closer approach temperature, true counter current flow, 80-90% less hold-up volume. Plate heat exchanger installation reduced installation costs, limited maintenance and operating costs. Less fouling, stress, wear and corrosion. Minimum energy consumption for maximum process effect. The product range is extremely wide and is used in duties for heating, cooling, heat recovery, evaporation and condensation in industries ranging from HVAC, refrigeration, engine cooling, dairy and food to heavier processes like chemical processing, oil production and power generation.

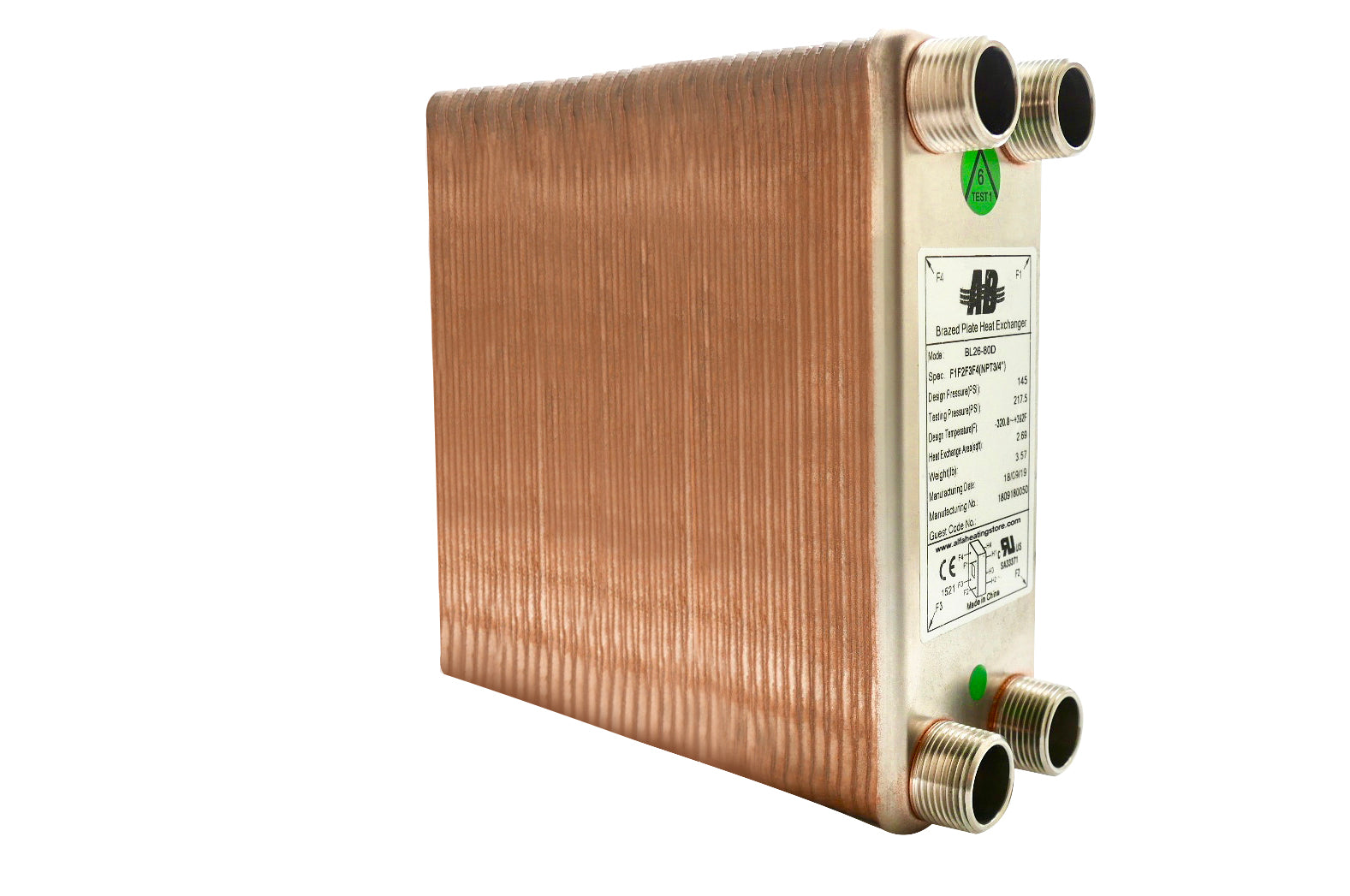

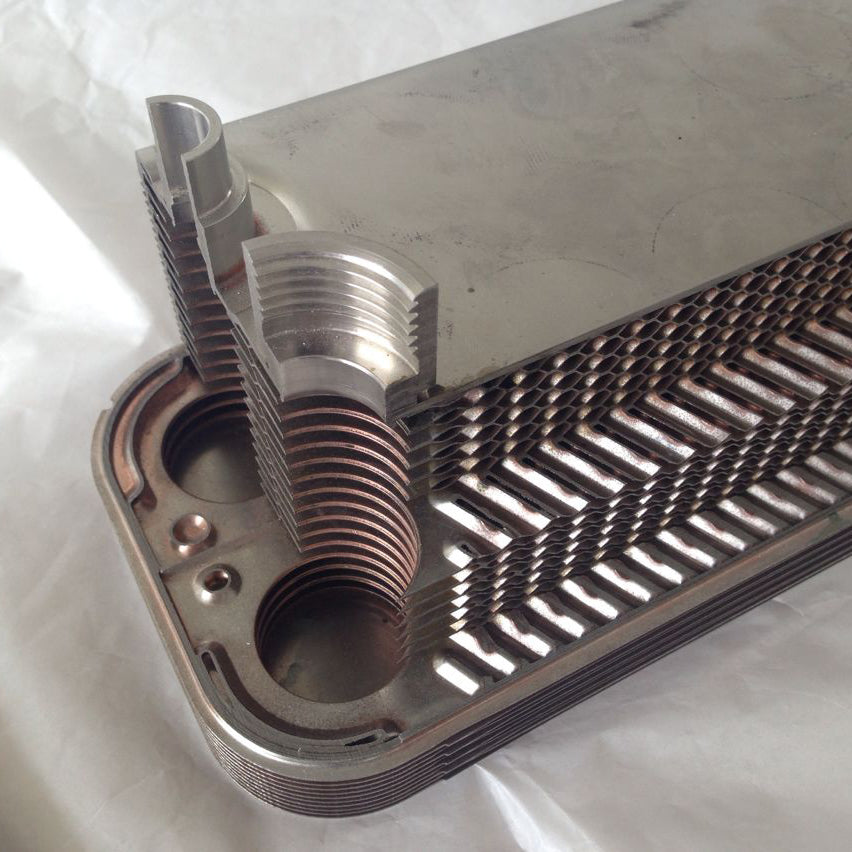

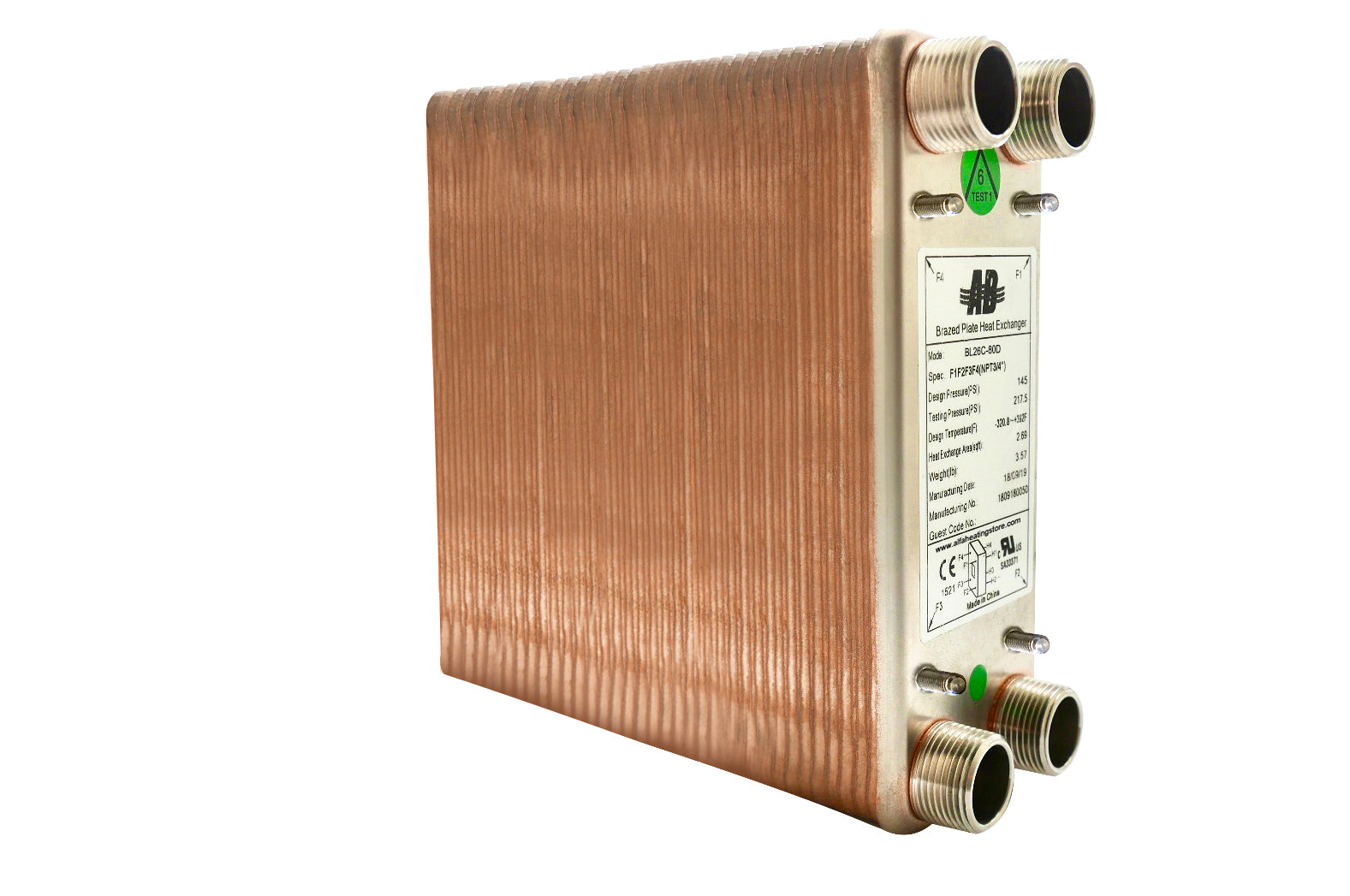

Built from stainless steel with copper or nickel brazing materials, stainless plate heat exchanger provide exceptional corrosion resistance. Pool plate heat exchanger feature corrugated plates that produce highly turbulent flow in a true counter-current direction. This results in high efficiency and a very compact hot heat exchanger design. With their compact size and super-thin stainless steel plates material content, they can be the most economical heat transfer choice. When you buying brazed plate heat exchangers online, shop with the most trusted brand like ALFA.

Built with high quality stainless steel 316L and copper, this model produces a counter-current flow to maximize heat efficiency. Lesser quality materials can cause problems in your heating system, which is why we only use the best materials for our products. To take your boiling wort down to cool and safe temperatures; A poorly constructed coil immersion chiller can take hours to chill wort and thin copper tubing can bend and crack which can cause water to rush out where it should not be, but this durable plate cools wort within minutes without leakage.

UL LISTED; Our plate heat exchangers come with a 1-year warranty to cover manufacturer defects.

APPLICATIONS: These can be used for Domestic Water Heating, Floor Heating, Snow Melting, District or Zone Heating Systems, Outdoor Wood Furnaces, Hydraulic and Lube Oil Coolers, Radiator Heating, Hydronic Heating, Solar Heating, Wood Boiler

Our list has 25 different variants of brazed plate heat exchangers, details showed in below.

FAQ

A brazed plate heat exchanger is a highly compact and efficient device used to transfer heat between two fluids. It consists of multiple thin stainless steel plates that are stacked and fused using copper or nickel brazing. Each plate creates a channel for fluids to flow in alternating directions, maximizing heat transfer in a very small footprint.

This design allows for:

- High thermal performance in limited spaces

- Minimal fluid hold-up volume

- Lower energy consumption and operating costs

These units are built for demanding heating and cooling applications. You’ll find them used across hydronic systems, district heating, refrigeration, engine cooling, and even food-grade systems, such as those used in brewing or dairy. Their stainless steel construction offers excellent resistance to corrosion, and the corrugated plate surface enhances turbulence for improved heat exchange efficiency.

Sizes range from small units capable of 80,000 Btu to large models pushing 1.3 million Btu. Their compact size = less space needed in tight installations. Their true counter-current flow = better temperature control and more precise operation. Installation is simple, and maintenance is limited. If you’re working with hot water, glycol, or non-aggressive chemicals, this type of exchanger is a practical, long-lasting choice.

The typical lifespan of a brazed plate heat exchanger ranges from 10 to 20 years, depending on its use, installation, and maintenance. These units are built from high-grade 316L stainless steel, brazed with copper or nickel, offering strong resistance to corrosion, thermal stress, and pressure fluctuations.

Key factors that affect lifespan include:

- Fluid quality (clean, filtered liquids extend system life)

- Proper sizing (a correctly sized unit avoids overloading)

- Correct installation (orientation, flow direction, and system pressure matter)

Units that are used with clean, treated water in domestic or HVAC systems usually last longer than those used in aggressive industrial settings. Still, compared to traditional shell-and-tube heat exchangers, brazed plate models offer longer service with less fouling or buildup.

Fewer mechanical parts = less wear and tear. Proper system filtration = reduced risk of clogging and internal corrosion. Most Alfa Heating models are UL-listed and backed by a 1-year warranty for manufacturer defects. However, with proper care, they often outperform minimum expectations.

Yes. A brazed plate heat exchanger is an excellent fit for solar heating systems. It acts as the interface between solar collectors and storage tanks, transferring heat from the solar loop to domestic hot water or hydronic systems. These exchangers are designed to handle the temperature swings typical of solar thermal applications, making them a reliable component in energy-efficient setups.

Their compact design is ideal for tight installations in residential and commercial systems. They support:

- Floor and radiant heating

- Pool heating

- Domestic water preheating

High efficiency = more usable heat harvested from your solar system. Their low internal volume also means faster temperature response. Unlike traditional heat transfer methods that require large tanks or extended piping, a brazed plate heat exchanger helps simplify the system while boosting performance.

When designing a solar thermal loop, selecting the right model with a suitable Btu capacity and connection size is crucial. Models from Alfa Heating come in multiple configurations, including ¾” to 1¼” ports and capacities exceeding 1 million Btu. They’re built to handle the job, even as solar gain and system demands fluctuate throughout the day.