Description

There are three methods employed for water-cooled marine petrol and diesel engines: direct, heat exchanger and keel cooling. Direct cooling of the cylinders and heads by seawater is unsatisfactory because the engine which was probably originally designed for radiator cooling – will run too cold and the sea-water will eventually ruin the cylinder block and heads. Keel cooling is suitable for small boats operating in shallow weedy water, but the need for pipework external to the hull is a severe limitation. Heat exchanger cooling is the most common method, the seawater being isolated in components that can be designed to withstand its corrosive effect.

Alfa Marine Heat Exchangers are fabricated with the distinctive spiral corrugated tube design. Its compact structure for effective use with high fluid velocities and low-pressure drops. The tube stack is fully floating, thus minimizing thermal stresses, and it can easily be removed should cleaning be necessary. Most marine products are made of cupronickel, stainless steel 316L or titanium which are highly corrosion resistant and therefore suitable for use with seawater. Some of the smaller units are fitted with neoprene end covers which can fit directly into the seawater pipework.

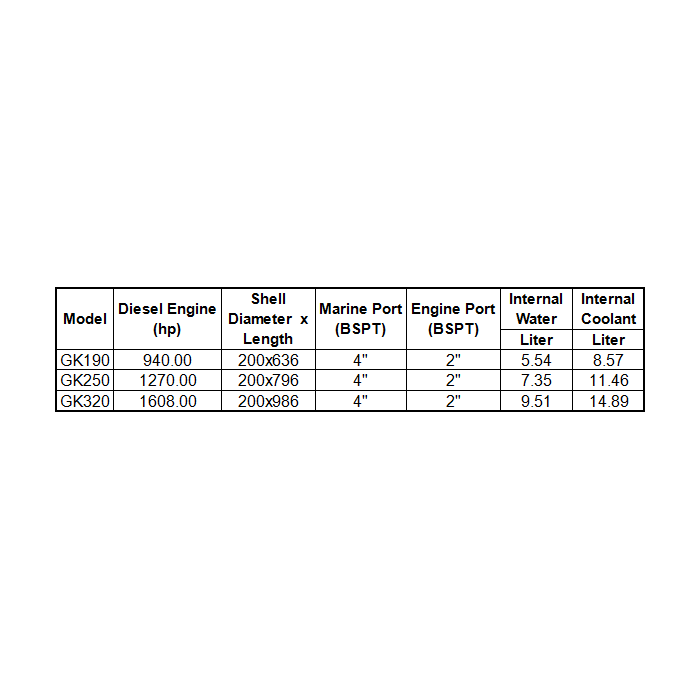

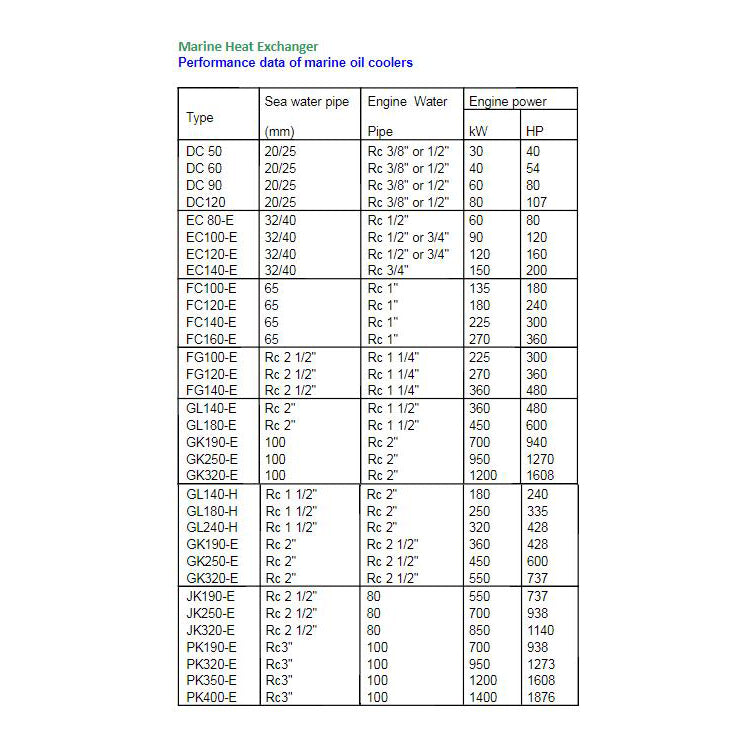

Specifications

- Model Options

SS316: GK190-E, GK250-E, GK320-E

Titanium: GK190-Eti, GK250-Eti, GK320-Eti - Marine Port (BSPT): 4"

- Engine Port (BSPT): 2"

- Max Working Pressure on Engine Water Side: 15 bar

- Max Working Pressure on Sea Water Side:15 bar

- Max Working Temperature:200 degrees C

*Customization Service

Mounting brackets are available.

We produce customized applications on different working pressure and temperature.